Stainless steel linear vibrating screen is made of 304 stainless steel, which is more durable and rust-proof, and is suitable for applications where any contamination of the processed material must be strictly avoided and absolute cleanliness and perfect corrosion resistance are required. , such as flour and feed processing, the food industry, the chemical or pharmaceutical industry.

The stainless steel linear vibrating screen can separate particles of different sizes and remove dust. The linear vibration track has higher work efficiency, and the screening and removal rate reaches 95%.

Stainless steel linear vibrating screen is a kind of vibrating screen machine specially used in food, medicine and chemical industry. It conforms to industry hygiene standards, is easy to clean, has no pollution and is corrosion-resistant.

1. Safe screening to eliminate foreign objects: Remove broken or undersized products such as lumps and other contaminants for final quality inspection.

2. Separation of different particle sizes in the same product: By installing sieves with different mesh sizes, the mixed materials are separated into finished products of different specifications according to the mesh number of the sieves to achieve particle homogenization.

The stainless steel linear vibrating screen is mainly made of SUS304 stainless steel, which is corrosion-resistant, high-temperature resistant, not easy to rust, clean and hygienic. It has the following advantages:

1. Stainless steel material, easy to clean - 304 or 316L stainless steel material is selected, which is anti-corrosion, rust-proof and high-temperature resistant. The surface of the equipment and the welding points are carefully polished and polished, and there will be no powder hanging during the screening process, which is convenient for cleaning and disinfection.

2. Contamination-free operation - all welded joints are seamless, ensuring no material deposits and zero possibility of material contamination.

3. Closed system - the whole machine has a sealed structure, which can eliminate the dust problem in the air and reduce the pollution to the material and the screening environment.

4. 5 grades classification - the screening efficiency is up to 96%, the screen mesh is optional from 1 to 5 layers, and the material can be screened into 2 to 6 different grades.

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Stainless steel linear vibrating screen can choose 304 or 316L stainless steel, the difference is as follows:

304 stainless steel is a kind of corrosion-resistant sulfuric acid, phosphoric acid, formic acid, urea, etc., suitable for general acid and alkaline materials.

316L stainless steel adds molybdenum element on the basis of 304, which improves its resistance to intergranular corrosion and oxide stress corrosion and reduces the tendency of hot cracking during welding. It also has the performance of chloride corrosion resistance. The price of 316 is 304. 2 times.

Stainless steel linear vibrating screen is composed of screen box, screen frame, screen mesh, vibration motor, motor pedestal, vibration damping spring, bracket and so on.

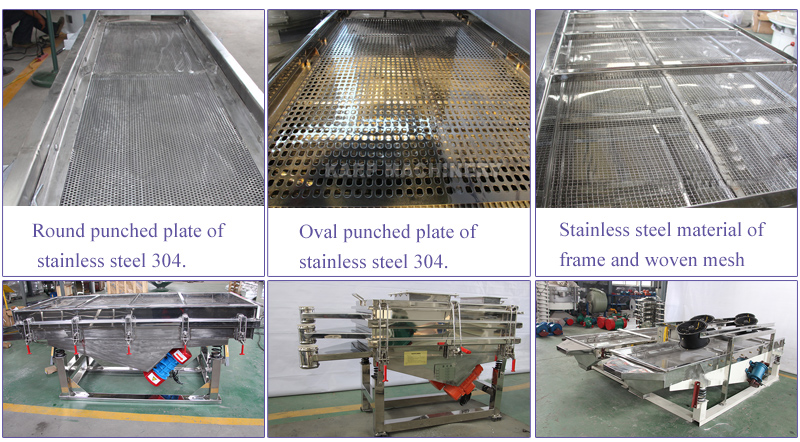

Screen: It is mainly used for screening materials. The aperture size of the screen is from 2 mesh to 200 mesh. There are many types and can be installed according to different screening requirements.

Screen box: The screen box is mainly used to hold the materials that need to be screened. The materials in the screen box are subjected to the action of the vibration motor to make a parabolic motion on the screen to achieve the purpose of screening.

Dust cover: The dust cover can solve the problem of dust when screening powdery materials;

Feed port and discharge port: The material enters the screen box from the feed port and is automatically discharged from the discharge port after being screened;

Vibration motor - force guide plate - shock-absorbing spring: the vibration force generated by the vibration motor drives the movement of the screen box through the conduction of the force-guide plate and the shock-absorbing spring, and the material moves on the screen, so as to achieve the purpose of screening.

| Product | Proportion | Mesh |

Capacity (kg/h) |

Model |

| Millet | 0.15 | 250 mesh | 600 | DZSF-515-2s |

| Quartz sand | 1.6 | 70 mesh | 30000 | DZSF-1540-3s |

| Raisin | 0.83 | 60 mesh | 6000 | DZSF-520-1s |

| Sunflower seeds | 0.04 | 80 mesh | 7100 | DZSF-525-1s |

| Plastic particles | 0.95 | 3 mm | 500 | DZSF-515-2s |

| Flour | 0.6 | 24 mesh | 1500 | DZSF-515-3S |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.