Suitable for industries such as medicine and food that have high requirements on hygienic conditions or are corrosive

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Model: DH-400/600/800/1000/1200/1500/1800

Layers: 1-5 layers

Mesh: 2 mesh - 500 mesh (0.028mm)

Output: 100kg/h-3000kg/h

Material: 304/316 stainless steel

Application: Suitable for screening and filtration of dry and wet materials that require absolute cleanliness and acidity, such as flour, feed, pharmaceutical powder, plastic granules, etc.

Commitment:

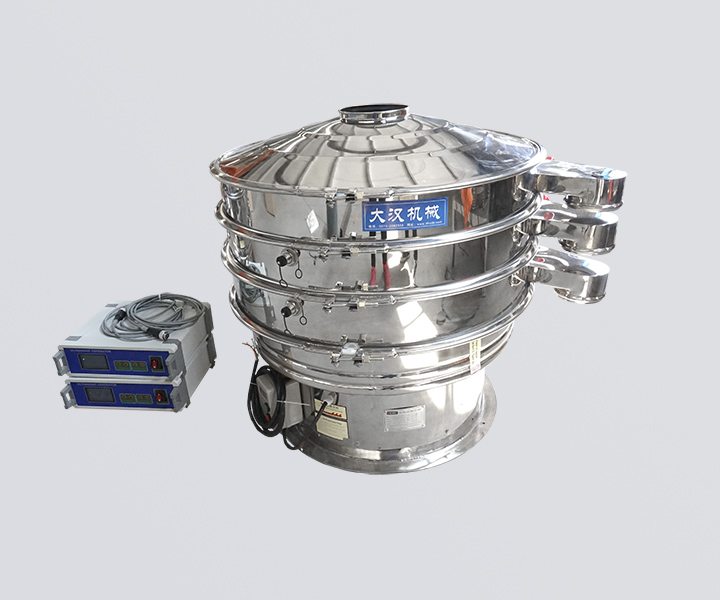

Stainless steel vibrating sieve is made of 304 or 316 stainless steel and is specially designed for the food or pharmaceutical industry. It can be cleaned and sterilized to avoid contamination of materials. It can protect the quality of powder or liquid products by removing excessive contaminants. The most hygienic and highest quality treatment of your screening material.

Stainless steel vibrating sieve is suitable for sieving in the 3-500 mesh range and allows up to 5 layers of sieves to separate 6 products in one operation.

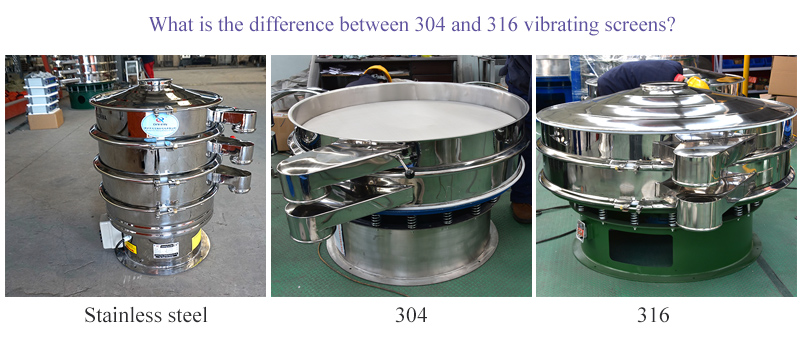

304 stainless steel vibrating sieve: 304 stainless steel is the most common form of stainless steel in the world, containing 16% to 24% chromium and up to 35% nickel, as well as small amounts of carbon and manganese, and can withstand the corrosion of most oxidizing acids. Durability makes 304 stainless steel shakers easy to sterilize, making them ideal for kitchen and food applications. However, it is susceptible to corrosion from chloride solutions or saline environments such as the coast (solutions as low as 25 ppm sodium chloride can start to corrode).

316 stainless steel vibrating sieve: It has almost the same physical and mechanical properties as 304 stainless steel, the main difference is that 316 stainless steel contains about 2% to 3% molybdenum, which increases corrosion resistance and is commonly used in many industries involving processing chemicals applications, as well as high-salt environments, such as the pharmaceutical industry, industrial and chemical industries.

Stainless steel vibrating sieve is a vibrating sieve designed for screening materials with high hygiene standards such as food and medicine, as well as materials with acid and alkali corrosiveness such as medicine and chemical industry.

1. Food industry

The hygienic standard required by the food industry is very high. The whole machine is made of 304 or 316 stainless steel, and the parts in contact with the material are not allowed to have any impurity contamination. The seals of the Stainless steel vibrating sieve are equipped with food hygiene standards.

Application materials: flour, pineapple juice, sesame, coffee, spices, beans, edible oil, etc.

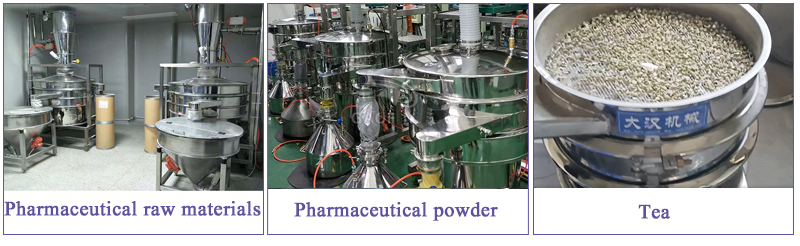

2. Pharmaceutical industry

The pharmaceutical industry has very strict requirements on the screening of materials. It must be stainless steel 304 or even 316. Before leaving the factory, the equipment must be cleaned several times with alcohol, and the entire machine is polished inside and outside without black spots and burrs.

Application materials: pharmaceutical raw materials with strict hygiene requirements such as pharmaceutical powder tablets, capsules, pellets, granules, raw materials, tablets, and drug residues.

3. Chemical industry: In the chemical industry, there are not only some materials with weak acidity, but also some materials with strong alkalinity. For materials that are not strong in acidity and alkalinity, stainless steel can be selected. For materials with strong acidity and alkalinity , plastic material is recommended.

Application materials: fertilizer, urea, resin powder, phosphor powder, etc.

4. Pollution treatment: easy to wipe, does not breed bacteria, and resists corrosion. Example: In some farms, impurity removal and filtration can be performed on the sewage in chicken, pig, rabbit, cattle and other farms.

Application materials: industrial wastewater, domestic sewage, calcium hydroxide slurry, etc.

No welds, hygienic operation

The whole machine has also been polished internally and externally, with no welds at the welds, high cleanliness and easy cleaning, which can ensure that the materials will not be polluted during the screening process, and meet the hygiene requirements of the food and pharmaceutical industries.

Fine mesh sieve

Screening to 500 mesh or 0.028mm, the finished product has a uniform particle shape, and the addition of bouncing balls made of silica gel can effectively prevent the screen hole from clogging and improve the screening accuracy and output.

Acid and alkali corrosion resistance, high temperature resistance

It is made of 304 or 316 stainless steel to avoid chemical reaction with acid and alkaline materials, and can resist high temperature within 200 degrees Celsius.

Closed system

The fully sealed structure can ensure that the materials will not appear dust flying and liquid splashing during the screening process.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 |

| DH-600 | 600 | 0.25 | |||

| DH-800 | 800 | 0.55 | |||

| DH-1000 | 1000 | 0.75 | |||

| DH-1200 | 1200 | 1.1 | |||

| DH-1500 | 1500 | 1.5 | |||

| DH-1800 | 1800 | 2.2 |

|

|

|

|

| Edged type | Gate type | Movable type | Explosion-proof type |

| heightened dust cover to prevent liquid materials from splashing | prolong the screening time of materials, suitable for fine powder and difficult-to-screen materials | increase the universal wheel, more flexible, suitable for changeable production environment | use explosion-proof motor, better sealing, suitable for environments with a lot of dust and easy to generate static electricity |

Stainless steel vibrating sieve generally consists of a screen cover (usually provided with a feeding interface), a screen frame (built-in screen components, which are formed by coil welding), a driving device (usually a vertical vibration motor), a vibration isolation device (a set of It is composed of several parts such as support spring), base, etc. Among them, the screen cover and screen frame are vibrating parts, and the other parts are non-vibrating parts. In addition, the base also has a supporting function.

Material for screen wire cloth: stainless steel 304, 304L, 316, 316L

Wire diameter: 0.025–2 mm

Mesh: 3–508 mesh

Aperture width: 0.025–6.87 mm

Open screening area: 25% – 71%

| Material | Mesh | Capacity (kg/h IT/h) |

odel |

| Chinese medicine powder | 100-300 | 400-600 | DH-600 |

| Wheat Flour | 20-80 | 1000 | DH-800 |

| Cocoa Powder | 300 | 700 | DH-800 |

| Ground Coffee | 20-80 | 400-800 | DH-600 |

| Powdered Sugar | 80-200 | 3500 | DH-1800 |

| Rice | 12-14 | 1200 | DH-1000 |

| Pineapple Juice | 100 | 3000 | DH-1200 |

| Plant Oil | 100 | 3800 | DH-1800 |

| Sesame | 20 | 1200 | DH-1000 |

| Honey Sugar | 80 | 200 | DH-600 |

| Dregs Of a Decoction | 60-150 | 3000 | DH-1400 |

| Forage | 40 | 2200 | DH-1600 |

| Brim Stone | 80 | 450 | DH-600 |

| Yeast Liquid | 32 | 8000 | DH-1000 |

| Capsule Pellets | 10-32 | 3000 | DH-1800 |

| Traditional Chinese Medicine Decoction Pieces | 2-10 | 2600 | DH-1400 |

Pharmaceutical Particle Grading

Purification and sorting through sieving to remove impurities to ensure the quality of pharmaceutical raw materials, made of the highest quality 316L grade stainless steel to ensure that metal impurities are reduced to a minimum.

Safely Sieving Flour

Industrial safety sieving vibrating sieve, used to remove contaminants from flour and protect operators, preventing foreign matter from entering the next process and causing food safety problems.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.