Commonly used in food processing, pharmaceutical, chemical processing and other industries that require strict hygiene standards and anti-pollution.

![]()

![]()

Price::$850.00-$6,400.00/Set

Consult now and enjoy a 10% discount

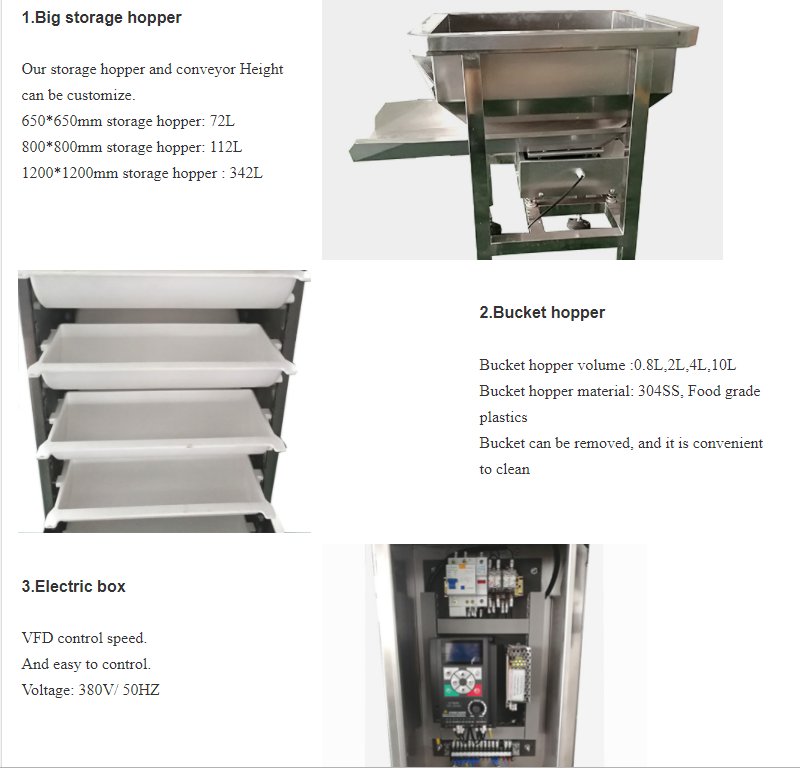

Bucket Material: Food Grade PP

Conveying Speed: 2-5 m³/h

Bucket Volume: 1.8L, 4.0L, and 6.0L (Customizable)

Discharge Height: 2-12 m

In-Feed Length: 863 mm

Out-Feed Length: 1930 mm

conveying capacity: 3-10m³/h

Number of Outlet(s):Single or Muti-dicharge outlets

Application: It is used in equipment or storage bins used in food processing, pharmaceutical, chemical and other industries to lift granular materials from low places or the ground to high places or above.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

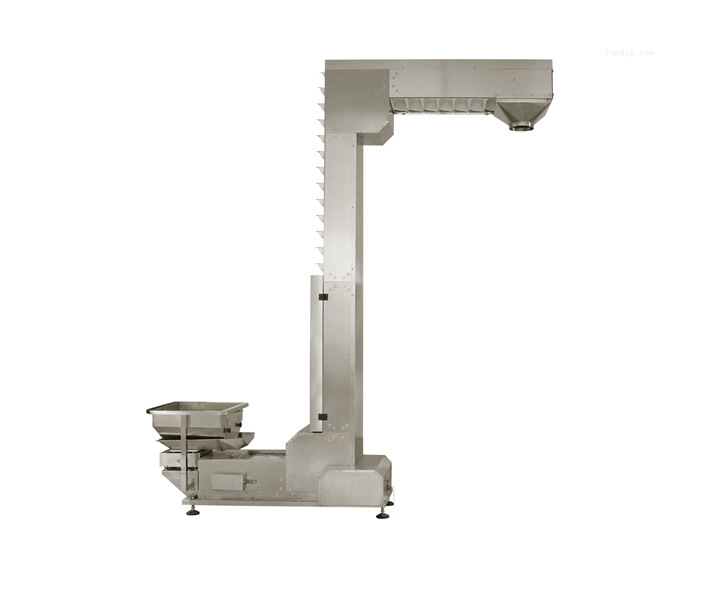

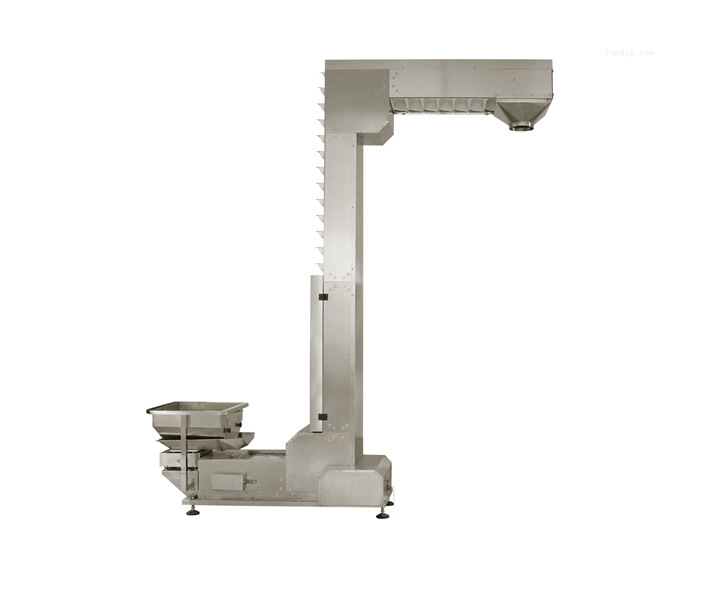

Stainless steel bucket elevator is a type of vertical material handling equipment used to lift bulk materials from a lower or ground level to a higher level or overhead processing equipment or storage bins. It is constructed using stainless steel material, which offers corrosion resistance, durability, and ease of cleaning.

Stainless steel bucket elevators are designed to handle a wide range of materials, including granular, powdery, or lumpy substances. They are available in various sizes and capacities to accommodate different material handling requirements.

Single Point Infeed: Materials enter the elevator system from one inlet of the elevator. This feeding method is suitable for situations where there is only one source of material or a single material flow is required.

Multiple Point Infeed: Materials enter the elevator system from multiple inlets of the elevator simultaneously or sequentially. This feeding method is suitable for situations where multiple sources of materials need to be processed at the same time or where materials need to be diverted from different sources.

Single Point Discharge: Discharge materials from one outlet of the elevator. In Z-type bucket elevators, a discharge hopper or a discharge port is usually used to discharge materials from the bottom or side of the elevator. This discharging method is suitable for situations where there is only one material receiving end or a single material flow is required.

Multiple Point Discharge: Discharge materials from multiple discharge ports of the elevator simultaneously or sequentially. This discharging method is suitable for situations where materials need to be diverted to different destinations or supplied to multiple receiving ends at the same time.

Stainless steel bucket elevators are suitable for various industries where bulk materials need to be handled in a hygienic and corrosion-resistant manner. Some common applications include:

Food Processing: Stainless steel bucket elevators are widely used in the food industry for handling ingredients, grains, grains, spices, nuts and other food products. They ensure the cleanliness and integrity of transported materials and meet the strict hygiene requirements of food processing.

Pharmaceutical Industry: In pharmaceutical production, stainless steel bucket elevators are used to lift and transport pharmaceutical powders, tablets, capsules and other materials. Stainless steel construction ensures compliance with strict hygiene and cleanliness standards, preventing contamination and maintaining product quality.

Chemical Processing: Stainless steel bucket elevators are used in the chemical industry to handle corrosive or abrasive materials such as fertilizers, salts, minerals and chemicals. The corrosion-resistant properties of stainless steel make it suitable for handling these substances safely and effectively.

Beverage Industry: Stainless steel bucket elevators are used in breweries, wineries and beverage production facilities to lift and transport raw materials such as malt, hops, grains and other raw materials. They provide hygienic and durable solutions to ensure quality and purity of the beverage production process.

Seed Processing: In seed processing plants, stainless steel bucket elevators are used to handle and transport seeds such as corn, soybeans, wheat and other grains. Stainless steel construction prevents contamination and maintains seed integrity during transportation.

Recycling Industry: Stainless steel bucket elevators are used in recycling facilities to process recyclable materials such as plastic pellets, glass fragments, metal scraps and other scrap materials. Stainless steel's corrosion resistance and durability make it suitable for handling these materials in harsh environments.

Corrosion resistance

Stainless steel has strong resistance to corrosion, rust and chemical reactions. This feature makes stainless steel bucket elevators suitable for handling materials in industries where cleanliness and hygiene are critical, such as food processing, pharmaceuticals and chemicals.

Hygiene and cleanliness

Stainless steel is easy to clean and maintain, making it ideal for applications requiring strict hygiene standards. Stainless steel bucket elevators can be thoroughly cleaned to prevent the build-up of contaminants, bacteria and odors. This feature is critical for industries where cleanliness is critical, such as food processing and pharmaceuticals.

Versatility

Stainless steel bucket elevators can handle a variety of materials, including powders, granules and bulk solids. They can be customized with different bucket sizes, shapes and configurations to meet specific material handling requirements, allowing for efficient and reliable vertical or inclined transportation.

Durability and strength

Stainless steel is a strong and durable material capable of withstanding heavy loads and harsh operating conditions. Stainless steel bucket elevators are designed to handle bulk materials and provide reliable performance over an extended period of time, reducing maintenance and replacement costs.

Long lasting

Stainless steel has excellent longevity and maintains its structural integrity over time. Stainless steel bucket elevators have a long life and can withstand the wear and tear of continuous material handling operations, reducing downtime and increasing productivity.

Easy to maintain

Stainless steel bucket elevators require minimal maintenance due to their durable and corrosion-resistant properties. Routine cleaning and inspections are usually enough to keep your equipment in top condition. The smooth surface of stainless steel also helps to easily remove any material residue, reducing downtime and maintenance costs.

Stainless steel Z type bucket elevator for feed

Stainless steel Z type bucket elevator for candy

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

The structure of stainless steel bucket elevator usually consists of the following components:

Frame structure: usually made of stainless steel material, providing overall support and stability. The frame structure includes components such as columns, beams, and bases, and its design and strength must be able to withstand the weight of the material and the hoist itself.

Bucket: used for loading and transporting materials. Buckets are usually made of stainless steel material for strength and corrosion resistance. The shape and size of the bucket can be customized according to material characteristics and processing requirements, such as square, round or special shapes.

Transmission system: used to provide power and drive the bucket to move in vertical or inclined directions.

Guide device: guides the bucket to move in the vertical direction and ensures smooth feeding and discharging of materials.Discharge device: The discharge device is used to control the discharge of materials from the bucket.

Safety devices: In order to ensure safe operation, stainless steel bucket elevators are usually equipped with safety devices, such as anti-lag devices, limit switches, emergency stop buttons, etc. These devices are used to monitor and protect the safety of the hoist during operation.

| Customer application examples | Conveying materials | Conveying capacity | Lift height |

| Food processing plants | Rice, flour, sugar, etc. | 1,000 kg/h | 5 meters |

| Chemical pharmaceutical factory | Powdered medicine | 500 kg/h | 3 meters |

| Grain storage facilities | Cereal, chaff | 2,000 kg/h | 8 meters |

| Plastic products factory | Granular plastic raw materials | 800 kg/h | 4 meters |

| Pulp and Paper Mills | Pulp and cardboard raw materials | 1,200 kg/h | 5 meters |

| Fine chemical plant | Granular chemical raw materials | 600 kg/h | 3 meters |

These examples are for reference only, and the actual application of stainless steel bucket elevators in different industries and application fields will vary. Conveying materials, conveying volume and lifting height all need to be customized and adjusted according to specific production needs and process requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.