Z type bucket elevator

Z type bucket elevator Stainless steel z type bucket elevator

Stainless steel z type bucket elevator Z type bucket elevator with multi-point feeding

Z type bucket elevator with multi-point feeding Z type bucket elevator with multi-point discharge

Z type bucket elevator with multi-point discharge Z type bucket elevator system

Z type bucket elevator system

Can be specially used in the food packaging industry to lift various bulk materials

![]()

![]()

Price:$850.00-$6,400.00/Set

Consult now and enjoy a 10% discount

Bucket Material: Food Grade PP Conveying Speed: 2-5 m³/h

Bucket Volume: 1.8L, 4.0L, and 6.0L (Customizable)

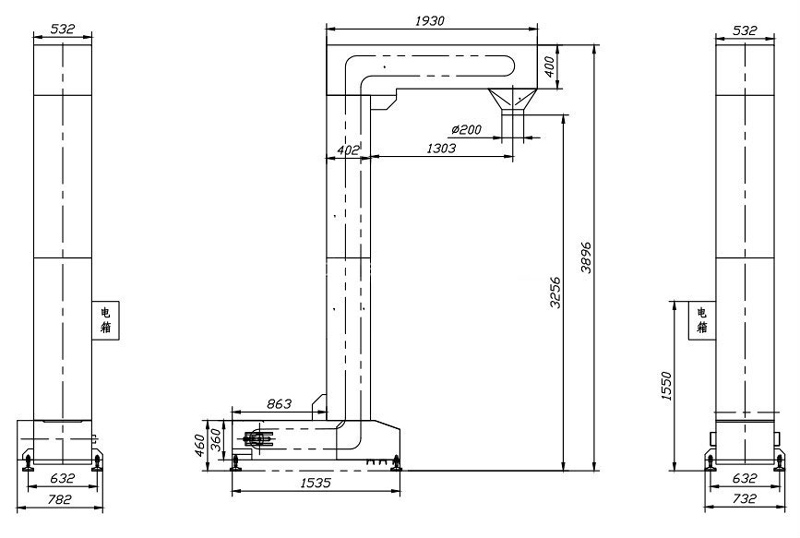

Discharge Height: 2-12 m

In-Feed Length: 863 mm Out-Feed Length: 1930 mm

conveying capacity: 3-10m³/h

Number of Outlet(s):Single or Muti-dicharge outlets

Application: Used for the promotion of granular materials such as granaries, grain processing plants, feed processing plants, and food processing industries, such as beans, potato chips, peanuts, candy, etc.

Commitment:

Stainless steel Z type bucket elevator shell is made of SUS304 or 316 stainless steel, and bucket is made of food-grade PP. It is used in industries with strong corrosiveness, high temperature or strict hygiene requirements, such as food and pharmaceutical industries, etc. The material will not be contaminated during the conveying process.

It helps to convey products from low to combination scales, vertical packaging machines or other equipment. It is suitable for vertical lifting of grains, pasta, candy, seeds and other granular, sheet, roll or irregular shaped materials, such as potato chips, coffee beans, nuts, puffed food, biscuits, chocolate, pet food, frozen food, etc. Broken or intact.

304 stainless steel: It is a widely used steel with good corrosion resistance, heat resistance, low temperature strength and mechanical properties, good hot workability such as stamping and bending, and no heat treatment hardening phenomenon (non-magnetic, convenient temperature- 196℃~800℃), can only be used for less corrosive materials, generally only suitable for weak acid, weak alkali or food, beverage and other production lines.

316L stainless steel: 316L stainless steel is a kind of molybdenum-containing stainless steel. It is added with 2-3% molybdenum element, which greatly improves its corrosion resistance and high temperature. Its corrosion resistance is better than 304 stainless steel, and it has good heat resistance. , suitable for screening strong acid and alkali materials, such as chemical industry.

Stainless steel Z type bucket elevator is made of stainless steel, which can prevent the material from being polluted. It is suitable for industries with high hygiene requirements such as food and medicine or industries that are corrosive.

Food industry: biscuits, gummies, marshmallows, small steamed buns, pancakes, chicken essence, milk tea, jelly, shrimp chips, potato chips, rice noodles, rice balls, dumplings, chocolate, peanuts, coffee, sugar, nuts, jelly beans, sunflower seeds , pistachios, walnuts, almonds, rice, millet and other granular powder foods.

Chemical industry: plastic granules, powder (PP PE PS), activated carbon, preservatives, additives, fertilizers, etc.

Pharmaceutical industry: pills, capsules, tablets, etc.

Stainless steel Z type bucket elevator for feed

Stainless steel Z type bucket elevator for candy

Food grade standard

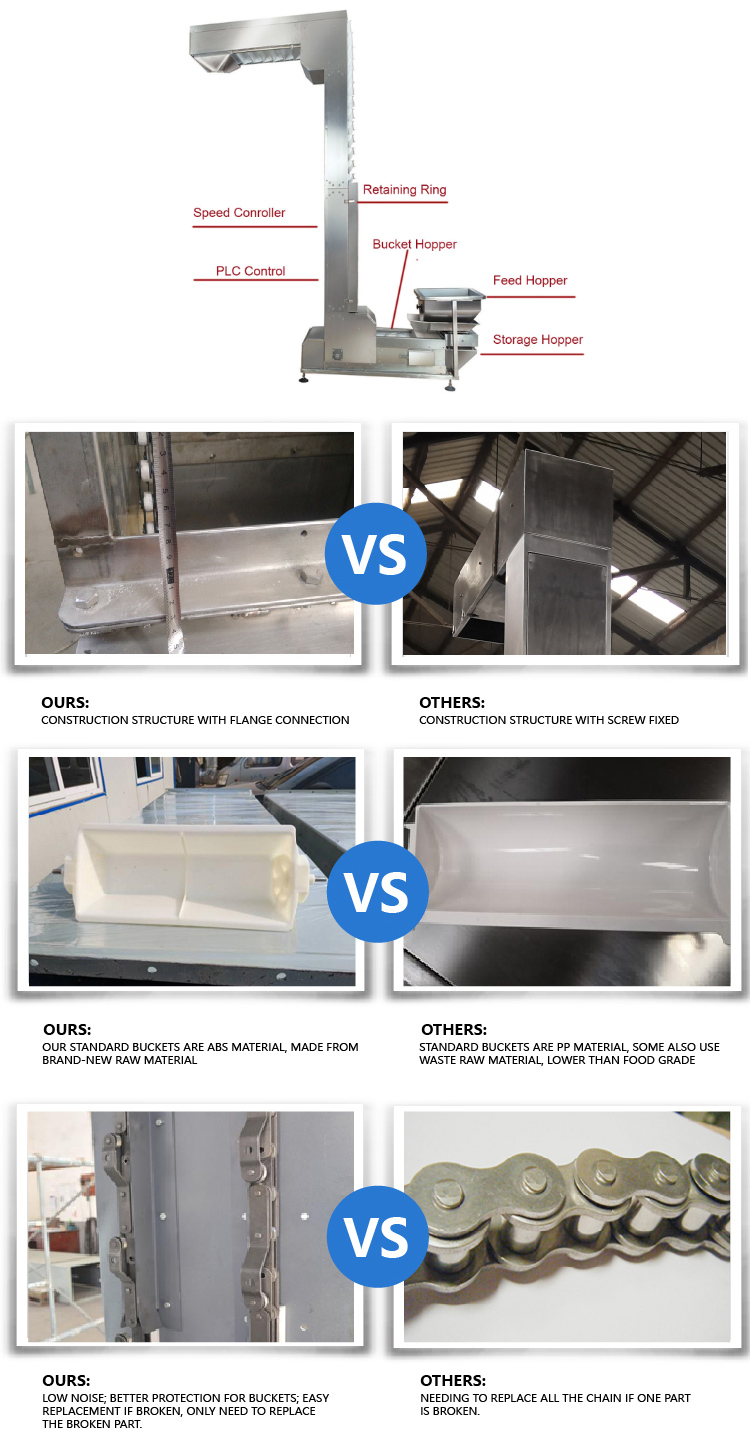

Made of SS304 or 316L stainless steel, the bucket is made of food-grade ABS, which is corrosion-resistant, not easy to rust, and not easy to contaminate the material.

Less broken

The inflow feeding method is adopted, and the non-traditional excavation feeding method is adopted, and the material crushing rate in the whole process is low.

Closed system

The hoppers are densely arranged, the shell of the whole machine is sealed, it is not easy to spread the material, and the dust flying caused by the leakage of materials during operation is reduced.

Multi-point feeding and unloading

2-7 discharge ports are available, multiple inlets and multiple discharge points can be combined into one system.

Uniform feeding

It can be equipped with a vibrating feeder, and the inflow-type uniform feeding can reduce the phenomenon of material omission.

Small footprint

With both horizontal and vertical conveying functions, one stainless steel Z type bucket elevator can meet the feeding needs of multiple silos, saving customers' equipment procurement costs.

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

Stainless steel Z type bucket elevator is mainly composed of casing, conveyor chain, hopper, driving wheel, steering wheel, tensioning device, guiding device, feeding port, discharging port, etc.

Bucket: Food grade reinforced polypropylene

Bucket Volume: 0.8L, 2L, 4L, 10L

Machine Frame: SS304/316 stainless steel

Stock Bin: 80L/120L

Motor to drive the chain wheel:motor can be selected for 220V/380V/415V, 50Hz/60Hz

Storage hopper and vibrating feeder: the hopper with small volume or big volume

Electric control box: start, stop, emergency stop, vibrate control, speed control, signal interface with other machine

Xinxiang Dahan Machinery Co., Ltd. has been focusing on the research and development, production and sales of conveying equipment for 15 years. Its main business is z-type and c-type bucket elevators. The thickness of the plate is between 4mm-8mm. The product manufacturing meets strict quality standards, and has obtained ISO and CE certification, various models are available from stock, and different models, materials, configurations or designs can be tailored according to the actual application of users according to the characteristics, capacity and lifting height of the material.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.