It can quickly lift grain and other materials to the target height in the vertical or inclined direction, improving production efficiency.

![]()

![]()

Price::$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Particle size: 25-70mm

Conveying capacity: 0.65-69.6m³/h

Conveying speed: 1.4-2m/s

Lifting height: 40 meters

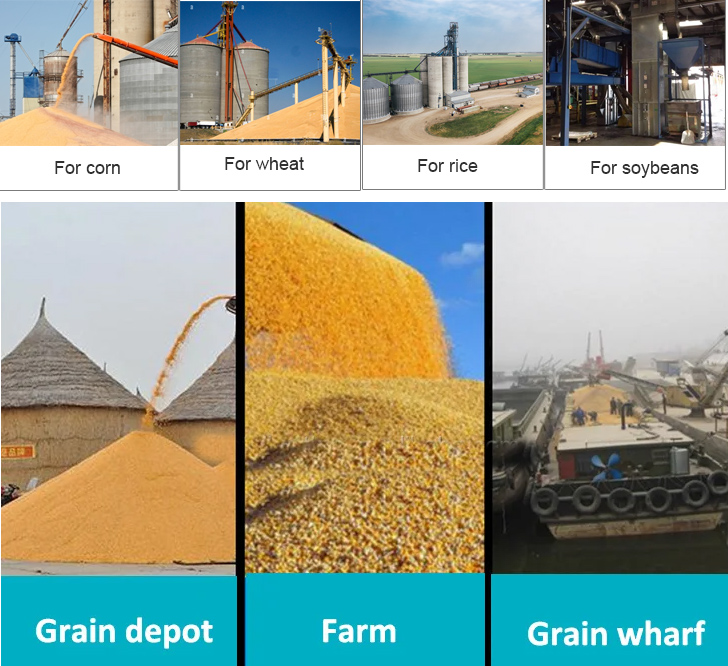

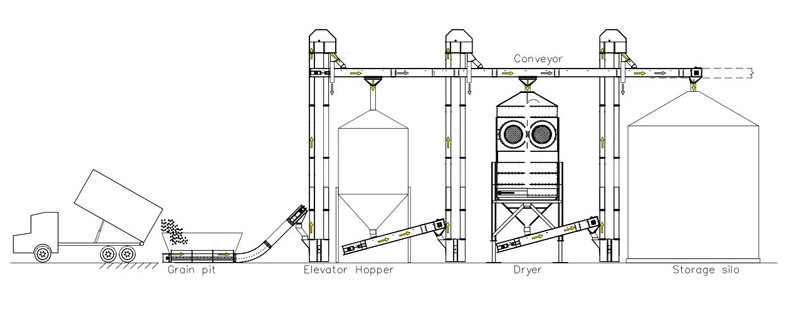

Application: Widely used in grain processing and storage fields. It is used to lift grain, grains and similar bulk materials from the ground or low places vertically or inclined to high places, such as storage warehouses, mills, drying equipment, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

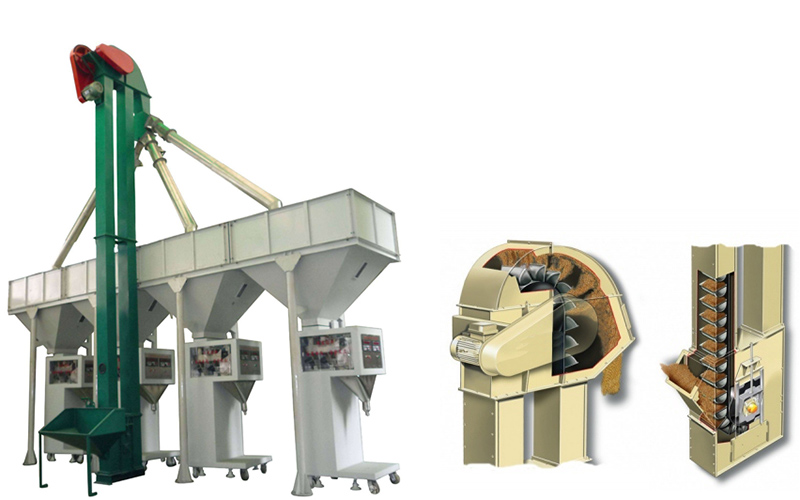

Grain bucket elevator is a type of bucket elevator specifically designed for the vertical transportation of grains. It is commonly used in the agricultural industry, including grain storage facilities, flour mills, feed mills, and other grain processing plants.

A grain bucket elevator consists of a series of buckets attached to belts or chains that move in a continuous cycle to lift grain vertically and transport grain horizontally. The main purpose of a grain bucket elevator is to efficiently and safely handle large quantities of grains such as wheat, corn, rice, barley and soybeans. It provides a reliable method for lifting grain from the ground or storage bins to a higher level such as silos, processing equipment or distribution systems.

The most common type of bucket elevator designed specifically to handle grains is the continuous bucket elevator. Continuous bucket elevators are well-suited for handling grains due to their ability to provide a continuous flow of material and accommodate high-capacity applications.

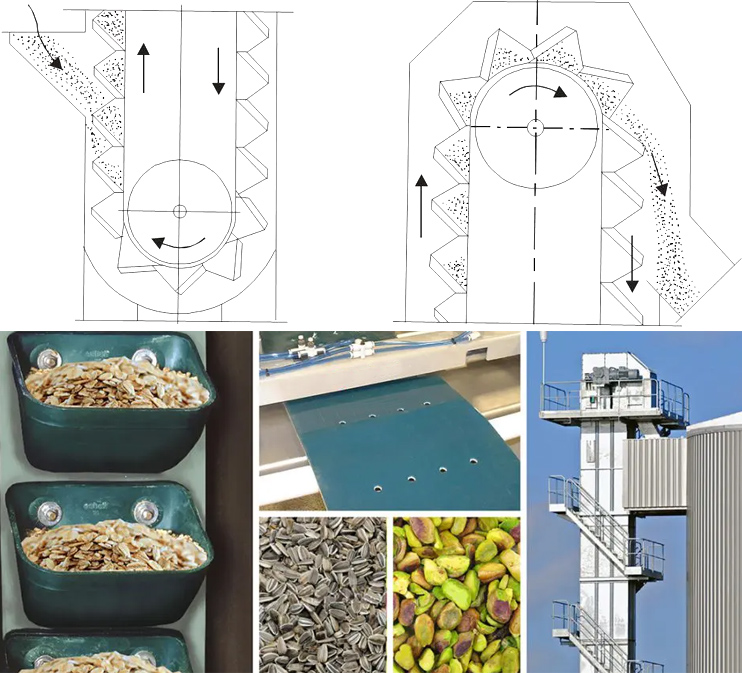

Continuous bucket elevators feature a series of evenly spaced buckets or cups that are attached to a belt or chain. The buckets are designed to scoop up the grains at the bottom of the elevator and carry them vertically to the desired discharge point. As the belt or chain moves, the buckets maintain a continuous flow of grains, ensuring efficient and uninterrupted handling.

Grain bucket elevators have a variety of applications in agricultural and grain handling facilities. Here are some common applications:

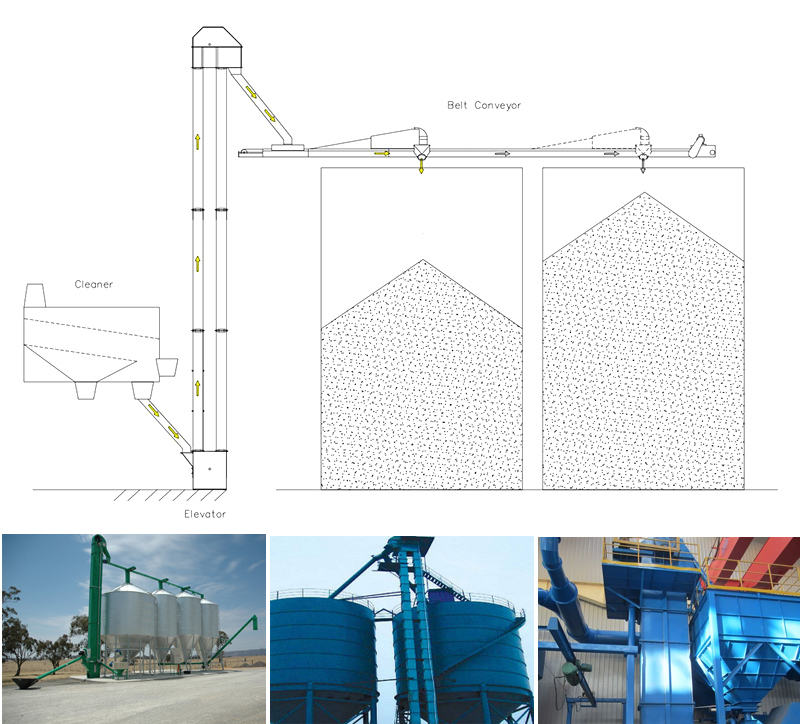

1. Grain storage facilities: used in grain storage facilities such as granaries and granaries. They are used to efficiently move grain from ground intake points to higher levels within storage structures. This allows for efficient vertical storage and easy retrieval of grain when needed.

2. Grain processing plants: It can be used to lift grain from cleaning or sorting equipment to milling or drying machines. This allows for a smooth, continuous flow of grain during processing operations.

3. Grain distribution and loading: Transfer grain from storage silos to ship loading systems or rail car loaders. This ensures efficient and reliable loading of grain onto carriers for domestic or international distribution.

4. Feed mills and livestock facilities: used to lift grain from storage silos or bins to mixing equipment, pellet mills or other processing machinery. This enables efficient feed production and distribution within the facility.

| Application occasions | Convey products | Use |

| Feed production line | Corn, soybeans, wheat bran, etc. | Lift raw materials from the ground to the mixer |

| grain storage facilities | Wheat, rice, soybeans, etc. | Lifting grain from the ground to storage bins or shipping equipment |

| Flour production line | Wheat flour | Lift wheat from storage area to mill |

| Brewing production line | Rice, distiller's grains, yeast, etc. | Promoting raw materials and by-products for alcoholic fermentation |

| Corn processing production line | Corn, corn bran, starch, etc. | Lift corn from receiving area to grinder, degerminator or storage bin |

Grain bucket elevators can transport various grains including wheat, corn, rice, soybeans, oats, barley, paddy, oats, sorghum, etc. They can adapt to the particle size, density, fluidity and moisture content of different grains, ensuring efficient and safe lifting of grain from the ground or storage bins to different processing equipment, storage bins or transportation devices.

Grain bucket elevators are generally suitable for handling a wide range of grain types. However, there are some grain characteristics that may pose challenges or require additional considerations when using bucket elevators. Here are a few examples:

1.Fine or powdery grains: Grain bucket elevators may not be ideal for handling very fine or powdery grains, such as flour or powdered spices. These types of grains can be prone to dusting or creating excessive fines during the lifting and discharge process. Specialized equipment, such as pneumatic conveyors or screw conveyors, may be more suitable for handling such materials.

2.Sticky or moist grains: Grains that have a high moisture content or sticky properties, like wet corn or soybeans, can present challenges in bucket elevators. They may adhere to the buckets or the elevator components, leading to issues such as clogging, reduced capacity, or increased wear. In such cases, modifications or additional equipment, such as bucket elevator boot dryers or grain conditioning systems, may be necessary to improve the handling of sticky or moist grains.

3.Abrasive grains: Some grains, such as rice with husks or certain varieties of barley, can be abrasive in nature. They may cause increased wear and tear on the bucket elevator components, including buckets, belts/chains, and discharge chutes. Selecting appropriate materials for the elevator components and implementing regular maintenance practices can help mitigate the effects of abrasion.

It's important to consider the specific characteristics of the grain being handled and consult with equipment manufacturers or experts in grain handling systems to ensure the suitability of a grain bucket elevator for a particular grain type. They can provide guidance on equipment selection, modifications, or alternative conveying methods if necessary.

High capacity

For efficient processing of large quantities of grain. They transport grain in bulk, handling materials faster and more efficiently than manual or alternative methods.

Vertical transportation

They transport grain from the ground to elevated storage silos or other processing equipment, optimizing space utilization and promoting smooth material flow.

Handle gently

Grain bucket elevators are designed to move grain skillfully, minimizing damage and maintaining grain quality. The shape of the barrel prevents grain spillage and maintains grain integrity, ensuring minimal product degradation during transport.

Dust control

Grain handling produces large amounts of dust, which can be hazardous to workers and equipment. Grain bucket elevators are equipped with dust control measures such as dust collection systems, enclosed or sealed housings, and dust-proof bucket connections. These features help minimize dust emissions and improve the overall work environment.

Automation and efficiency

Can be integrated into automation systems for efficient, continuous material handling. They can be equipped with sensors, controls and monitoring equipment to optimize operations, increase productivity and reduce labor requirements.

Versatility

Can handle a variety of grain types including wheat, corn, barley, rice and more. They can accommodate different particle sizes and densities, making them suitable for a variety of grain processing and storage applications.

Security function

Equipped with safety devices to prevent overloading, belt deviation or other potential hazards. These safety features help ensure reliable, safe operation of equipment, protecting workers and the grain itself.

Customizable configuration

Grain bucket elevators can be customized to fit specific facility layouts, space constraints and processing requirements. They can be designed with adjustable height and capacity to suit different grain handling applications.

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

Grain bucket elevators have several options to choose from in terms of design and configuration to meet different needs and application scenarios. Here are some common options:

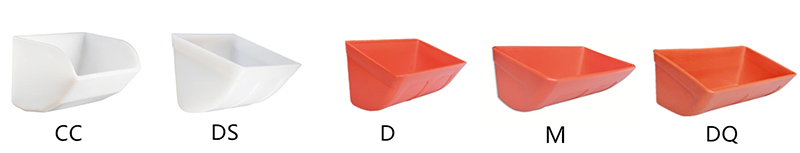

1. Bucket shape: The bucket of the bucket elevator can have different shapes, such as standard bucket, shallow bucket, deep bucket, etc. The shape of the bucket can be selected according to the characteristics and handling requirements of the material to maximize the loading capacity and conveying efficiency of the material.

2. Transmission mode: There are usually two options for the transmission mode of bucket elevators: belt transmission and chain transmission. Belt drives are better suited for lighter loads and lower speed applications, while chain drives are better suited for heavier loads and higher speed applications. When choosing a transmission method, you need to consider the weight of the material, the conveying speed, and the reliability and maintenance of the equipment.

3. Bucket spacing and bucket capacity: The bucket spacing and bucket capacity of the bucket elevator can be adjusted according to the characteristics and processing requirements of the material. A larger bucket capacity can improve the material conveying efficiency, while a smaller bucket spacing can increase the load-bearing capacity of the bucket elevator.

4. Safety devices: In order to ensure the safety of operators and the normal operation of equipment, bucket elevators are usually equipped with various safety devices, such as limit switches, speed monitoring devices, blockage detection devices, etc. Choosing appropriate safety devices can improve the safety and reliability of your equipment.

5. Dust-proof and explosion-proof design: In some special environments, such as places with flammable or explosive dust, bucket elevators can be designed to be dust-proof and explosion-proof. This includes measures such as sealed designs, dust covers and explosion-proof electrical appliances to ensure safe operation of the equipment.

6. Material selection: Appropriate materials can be selected for the components and parts of the bucket elevator according to the properties of the material. For example, for wet or corrosive materials, stainless steel or corrosion-resistant materials can be selected to extend the service life of the equipment.

The following is a sample table showing some application examples of grain bucket elevators. Specific application parameters may vary depending on different engineering projects and equipment specifications.

| Applications | Convey products | Conveying capacity | Conveying height |

| Grain storage facilities | Wheat | 5000 cubic meters/hour | 30 meters |

| Grain processing plant | Corn | 2000kg/hour | 20 meters |

| Feed production equipment | Soy flour | 3000kg/hour | 10 m |

| Grain mill | Wheat flour | 1000kg/hour | 15 meters |

| Granular Materials Storage Facility | Rice | 8000 cubic meters/hour | 40 meters |

Xinxiang Dahan is a manufacturer specializing in the production of grain bucket elevators. They focus on designing and manufacturing high-quality grain bucket elevator equipment for grain processing and material transportation fields. The company's products have stable performance, reliable quality and wide application, and are favored and trusted by customers in the grain processing industry. Xinxiang Dahan is committed to providing customers with customized solutions to meet the needs of different grain processing sites.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.