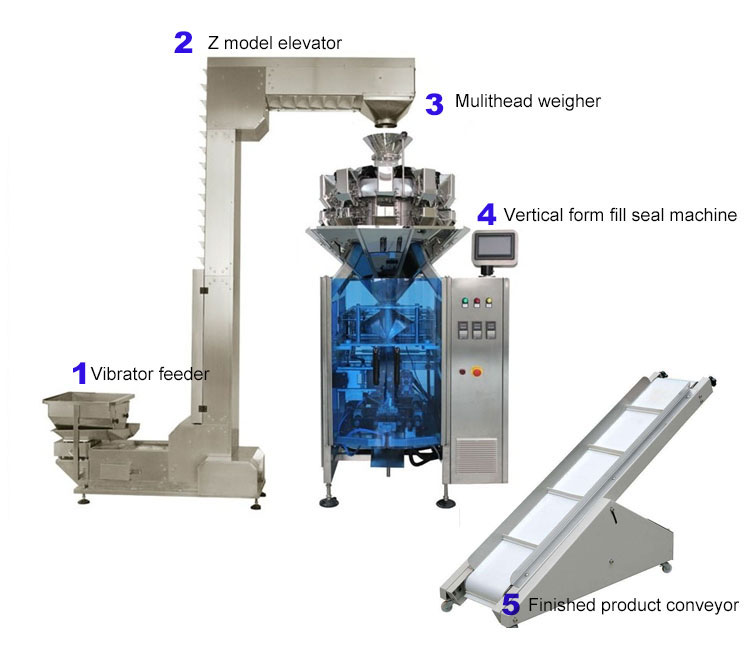

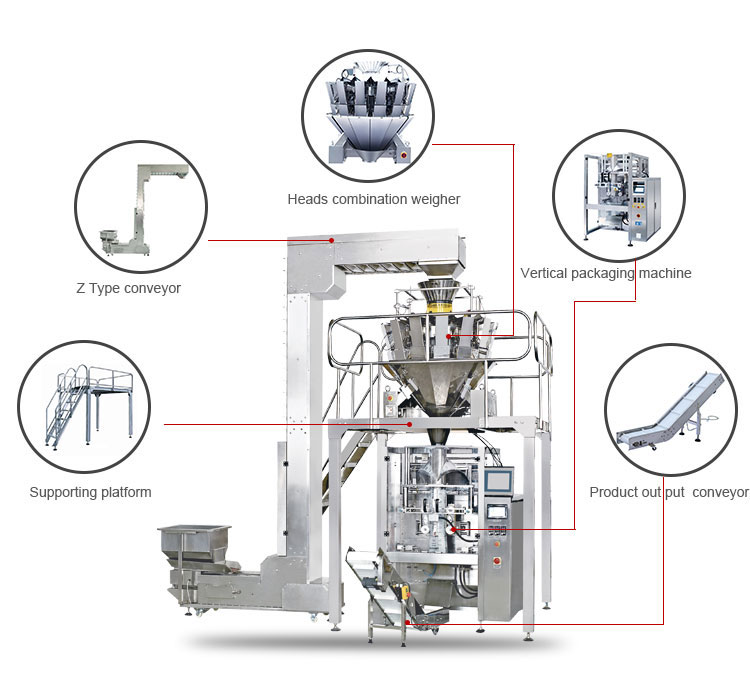

The supporting Z Type Bucket Elevator for packaging machine is one of the important equipment in the process of producing or processing products, and the matching Z Type Bucket Elevator is a machine used to move the required materials from one place to another. They are often used together to increase production efficiency and reduce labor costs. The following will introduce the application, structure and model of the Z-type elevator supporting the packaging machine.

When the Z-type rotary bucket elevator is working, the geared motor drives the two sprockets to move synchronously through the bearing, so that the two chains meshing with it move synchronously on the closed track. When the material is transported to the feeder, it slides into the horizontally forward hopper, because the material slides into the hopper instead of being scraped by force, so the material will not be broken.

The synchronous movement of the two chains makes the hopper between the two chains move continuously on its closed track. Under the action of the tipping bucket device, the hopper is turned over, and the materials in the hopper fall into the matching equipment temporary storage bin from the discharge port of the elevator.

The Z-type hoist matched with the packaging machine is widely used in food, medicine, chemical industry, metal, electronics, plastics and other industries. Use the Z-type elevator to raise the raw materials or packaged products from the ground to a suitable height, and cooperate with the packaging machine to realize the automated production process, thereby improving production efficiency and greatly reducing the labor intensity of workers.

The body of the Z-type hoist is made of stainless steel, with a smooth and beautiful appearance, compact structure and small space occupation. It is mainly composed of automatic feeding device, conveyor belt, hoist and auxiliary device. The automatic feeding device adopts the suspended spiral lifting motor to send the material to the conveyor belt, and the conveyor belt sends the material to the feeding port of the hoist, and the hoist delivers the material to the lower transportation device.

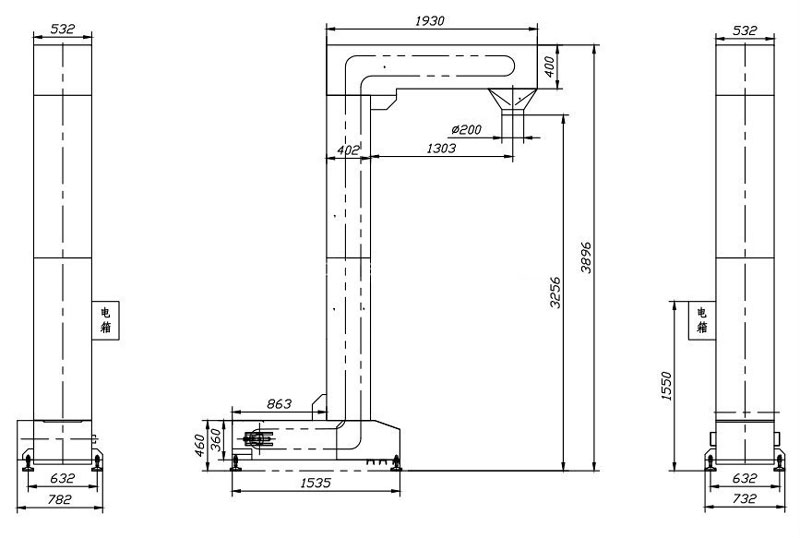

There are many types of Z-type elevators, which are generally classified according to parameters such as carrying capacity, conveying distance, and lifting height. Here are a few common Z-type elevator models:

1. ZDS-1 hoist: the carrying capacity is about 1 ton/hour, the conveying distance is about 60m, and the lifting height is about 4m.

2. ZDS-2 hoist: the carrying capacity is about 2 tons per hour, the conveying distance is about 90m, and the lifting height is about 6m.

3. ZDS-5 hoist: the carrying capacity is about 5 tons per hour, the conveying distance is about 120m, and the lifting height is about 8m.

In a word, the Z-type elevator for packaging machine is a very useful industrial machine, which can play a key supporting role in production, enhance production efficiency and reduce labor costs. With the continuous development of automation technology, Z-type hoists are gradually being widely used and will make important contributions to the sustainable development of industrial manufacturing.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.