The rotating impeller is used to impact the material and continuously lift the material.

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-142 tons/hour

Lifting height: ≤40 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

Application: It is used to continuously lift materials and throw them out through impact force. It is suitable for various industries.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

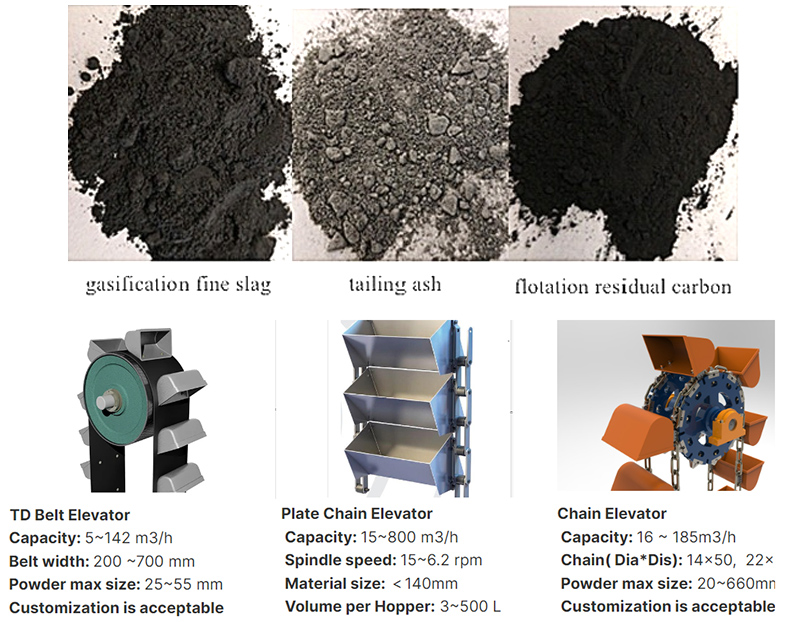

Slag Bucket Elevator is a piece of industrial equipment used to transport slag, a molten waste product from various industrial processes, from a lower position to a higher one. Its main components include motor, transmission device, main frame, lifting bucket, and guide roller , tail wheel, sprocket, chain, etc. The motor drives the transmission device to drive the chain to rotate, so that the lifting bucket circulates along the chain to transport the material from the bottom to the top.

Slag bucket elevators are suitable for various industrial fields, such as mining, construction materials, metallurgy, etc. They are used to vertically lift bulk materials, improve production efficiency, reduce labor costs, and ensure the smooth operation of production lines. It has a simple and solid structure and reliable operation. It is one of the important material conveying equipment.

Slag bucket elevators are used in a variety of industrial applications, including:

Transporting slag from a furnace to a disposal site

Feeding slag into a processing plant

Loading slag into trucks or railcars for transport

Common application occasion:

Steel Industry: Slag bucket elevators are commonly used in steel plants for the vertical transportation of slag generated during the steelmaking process.

Mining Industry: In mining operations, slag bucket elevators help move slag material efficiently within processing plants or between different stages of the production process.

Power Plants: Power generation facilities that use coal or biomass often employ slag bucket elevators to handle ash and slag materials produced during combustion.

Purposes of slag bucket elevator:

Vertical Conveying: Slag bucket elevator is designed to transport bulk materials vertically from the bottom to the top to achieve efficient vertical material transportation.

Improve production efficiency: Through the use of elevators, factories and enterprises can quickly and continuously transport materials, improve production efficiency, and reduce production costs.

Ensure product quality: Slag bucket elevator can avoid mixing and contamination of materials during transportation, ensuring product quality and stable operation of the production line.

The working principle of slag bucket elevator is that the motor drives the transmission device to drive the chain to rotate, so that the lifting bucket circulates along the chain. When the lifting bucket moves upward along the chain, the bulk materials at the bottom are loaded into the bucket. As the lifting bucket moves, the materials are lifted vertically to the top. At the top, material is unloaded by gravity or other means. Subsequently, the lifting bucket returns to the bottom and the next round of lifting is cycled. This cyclic operation process realizes the vertical transportation and lifting of bulk materials.

Efficient processing

Slag bucket elevators can handle large amounts of slag efficiently. Its design allows slag to be lifted and transferred quickly and continuously, improving processing efficiency and reducing the need for manual operations.

Flexible to adapt

Slag bucket elevators can be customized according to different slag characteristics and processing requirements. Parameters such as lift speed, lift height and capacity can be adjusted to meet the needs of specific applications.

Wear resistance

Slag bucket elevators usually use wear-resistant materials and structural designs to resist the wear and impact of slag. This helps extend the life of the equipment and reduces maintenance costs.

Automation

The slag bucket elevator can be integrated with the automated control system to achieve automated operation and monitoring. This helps improve production efficiency, reduce labor costs, and ensure the stability and consistency of the production process.

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

Slag bucket elevators have several design features that make them suitable for handling slag:

1.Heavy-duty construction: They are made from thick steel plates and other robust materials to withstand the weight and impact of slag.

2.Heat-resistant materials: The buckets, belts, and chains are made from materials that can withstand the high temperatures of slag, which can reach up to 1,200 °C (2,192 °F).

3.Wear-resistant materials: The buckets and other components that come into contact with slag are made from wear-resistant materials to minimize wear and tear.

4.Dust control systems: These systems help to suppress dust generation during operation to provide a safer working environment.

5.Water cooling systems: In some cases, slag bucket elevators may have water cooling systems to help cool the slag and prevent damage to the equipment.

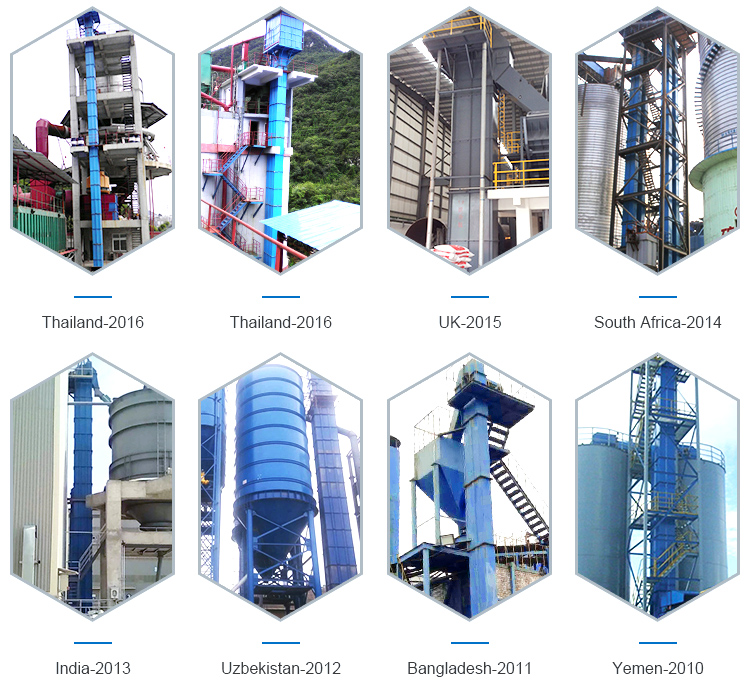

The slag bucket elevator produced by Xinxiang Dahan Factory played an important role in a mining project in Bangladesh. With its stable performance and efficient conveying capacity, the elevator successfully transported a large amount of slag from the bottom to the upper processing equipment, achieving rapid and efficient lifting of the slag. The customer highly praised the reliability and efficiency of the elevator, believing that it saved production costs and improved production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.