Choosing a suitable slag bucket elevator is crucial to efficiently handle slag and improve operating results. This article will look at some of the key factors to help you make an informed decision when choosing a slag bucket elevator.

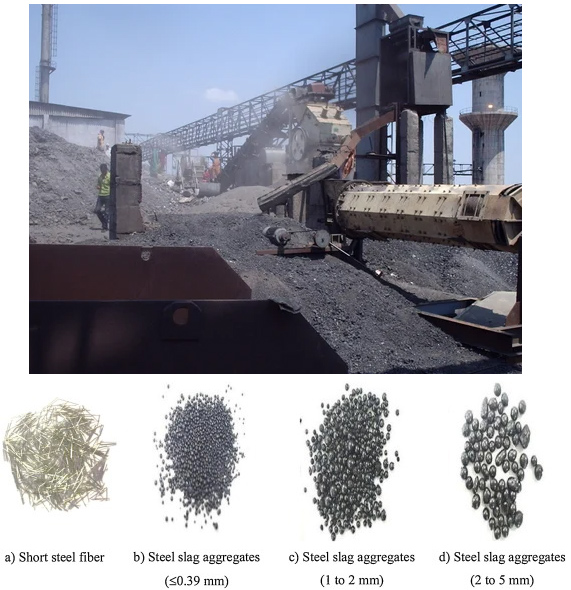

Temperature: Knowing the maximum temperature of your slag is crucial. The elevator's components, particularly buckets and belts, need to be rated for those temperatures to ensure safe operation.

Size and abrasiveness: The size and abrasiveness of your slag particles will influence the bucket design and material selection. Larger or more abrasive slag may require heavy-duty buckets with thicker walls and wear-resistant materials.

Moisture content: If your slag has any moisture content, it can cause issues like sticking and clumping. You may need an elevator with special features to address this, such as scraper blades or anti-adhesion coatings.

| Size | Temperature | Moisture content | Selection suggestions |

| less than 5 mm | 1000-1400°C | 1-5% | You can choose a bucket elevator with a larger bucket volume, such as a chain bucket elevator or a belt bucket elevator. |

| 5-25 mm | 900-1300°C | 2-7% | You can choose bucket elevators made of materials that are resistant to high temperatures, such as stainless steel bucket elevators or cast iron bucket elevators. |

| 25-50mm | 800-1200°C | 3-10% | You can choose a bucket elevator with an effective discharge method, such as a scraper bucket elevator or a vibrating bucket elevator. |

| greater than 50 mm | 700-1100°C | 5-15% | You can choose a bucket elevator with a smaller bucket volume, such as a hopper type bucket elevator or a Z-type bucket elevator. |

Quantity of slag to be transported: Determine the amount of slag you need to move per hour. This will help define the elevator's capacity and bucket size.

Desired speed: Consider how quickly you need the slag to be transported. This will factor into the motor size and overall design of the elevator.

The conveying capacity formula of the bucket elevator is as follows:

Q = 3.6V•a/t•ψ•γ (t/h)

in:

Q: Bucket elevator conveying capacity (t/h)

V: Chain (belt) speed (m/s)

a: Dou Rong (L)

t: Bucket distance (m)

ψ: filling coefficient, which decreases with the increase of speed and increases with the increase of material accumulation angle.

γ: Material bulk density (t/m³)

Example:

Assume there is a bucket elevator with a chain speed of 1 m/s, a bucket capacity of 50 L, a bucket distance of 2 m, a material filling factor of 0.8, and a slag packing density of 1.5 t/m³. Then the conveying capacity of the bucket elevator is:

Q = 3.6 × V × a / t × ψ × γ

Q = 3.6 × 1 × 0.05 / 2 × 0.8 × 1.5

Q ≈ 13.5 t/h

Therefore, the conveying capacity of this bucket elevator for slag is approximately 13.5 t/h.

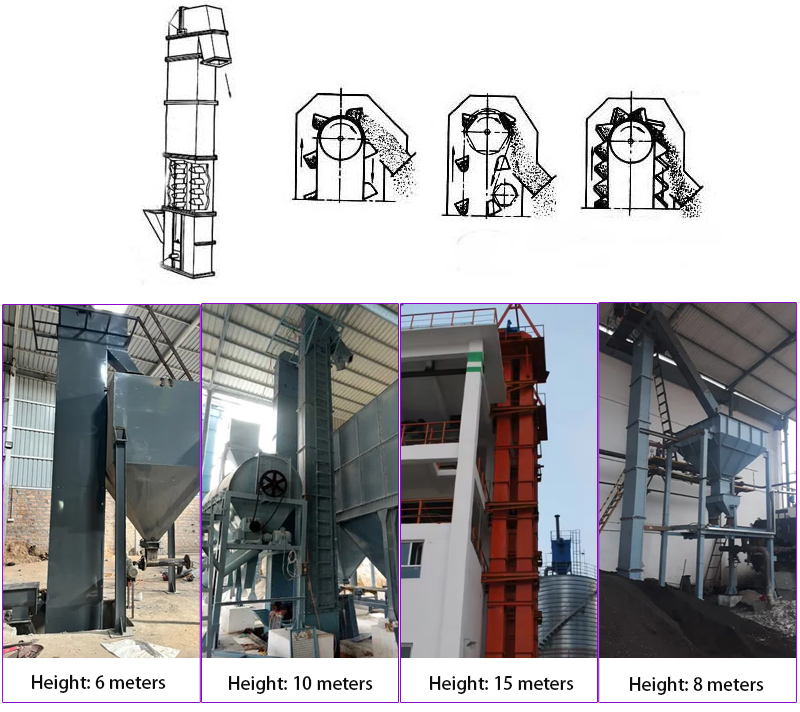

Available space: Measure the available space for the elevator and ensure the chosen model fits comfortably.

Discharge height and location: Determine the height at which the slag needs to be discharged and choose an elevator with a suitable discharge point.

Feeding method: Decide how the slag will be fed into the elevator. This could be from a hopper, conveyor, or directly from the furnace.

Dust control systems: If dust generation is a concern, consider an elevator with a robust dust control system to maintain a safe work environment.

Water cooling systems: For very hot slag, a water cooling system on the elevator might be necessary to prevent overheating and equipment damage.

Safety features: Look for elevators with safety features like overload protection and emergency shut-off switches.

Budget: Slag bucket elevators come in various price ranges depending on size, features, and capacity. Define your budget and choose an elevator that meets your needs within that range.

Supplier reputation: Research potential suppliers and choose one with a good reputation for quality, reliability, and after-sales service.

By carefully considering these factors and consulting with a qualified supplier, you can select the right slag bucket elevator that efficiently and safely handles your specific slag handling requirements.

Thank you for visiting our articles page! Please feel free to click the link below ((https://www.dahanmachine.com/product-center/Slag-Bucket-Elevator.html)) to enter our product page and learn more details about our products. If you have any questions or require further assistance, please feel free to contact our team. We look forward to providing you with an excellent product and service experience!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.