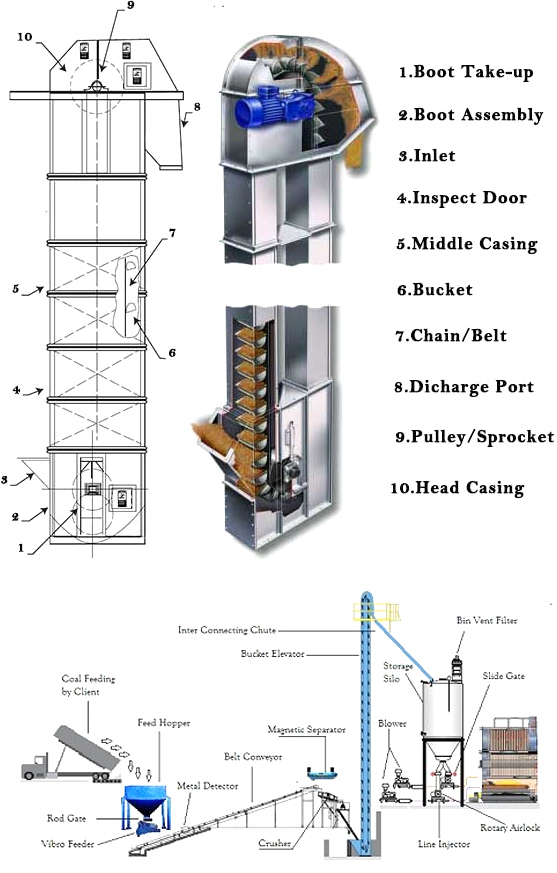

It is an efficient, continuous and vertical lifting machine for bulk coal.

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Type: Belt/Chain

Material particle size: 25-70mm

Lifting capacity: 5.4-142 tons/hour

Lifting height: ≤40 meters

Lifting speed: 1.4-2 m/s

Material: carbon steel, stainless steel

Application: It is used in coal mines, thermal power plants, coking plants and other industries to lift coal from the ground to the required height to provide raw materials for subsequent processing or power generation.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Coal bucket elevator is a type of bucket conveyor specifically designed for the vertical transportation of coal within industrial applications. It is widely used in coal mines, power plants, and other industries where coal is mined, processed, or utilized as a fuel.

By utilizing a coal bucket elevator, industries can achieve efficient and reliable vertical transportation of coal, ensuring a continuous flow of the material while optimizing production processes. The robust construction, wear resistance, dust control measures, and safety features make coal bucket elevators suitable for handling coal in various industrial applications.

The purpose of a bucket elevator in coal handling is to efficiently and vertically transport coal and related materials, such as coal dust, coal fines, or coal chunks, from one level to another within a coal handling system. It helps to streamline the coal handling process, ensuring a continuous flow of coal and facilitating the loading, unloading, and storage operations in power plants, coal mines, and other industrial facilities.

Coal bucket elevators are widely used in the following common applications:

1. Thermal power plant: Coal bucket elevator is used to transport coal from coal piles or bunkers to coal-fired boilers or coal crushing equipment to ensure the continuity and accuracy of fuel supply.

2. Coal mines: Coal bucket elevators are used in underground or open-pit coal mines to lift coal from mining areas or coal storage areas to loading points or processing equipment to improve the transportation efficiency and production capacity of ore.

3. Coal processing plant: Coal bucket elevators are used to transport raw coal or coal products from different processing units (such as coal washing equipment, crushers and screening equipment) to storage areas or the next processing stage.

Efficient transportation

The bucket elevator efficiently transports coal vertically, allowing for the smooth and continuous movement of coal from one level to another.

Increased productivity

By automating the coal transportation process, the bucket elevator reduces the need for manual labor and speeds up coal handling operations.

Space-saving design

The vertical nature of the bucket elevator requires less floor space compared to horizontal conveyors, making it suitable for installations where space is limited.

Dust control

Bucket elevators are equipped with enclosed casings and dust collection systems, which help to minimize dust emissions during coal transportation.

Versatile handling capabilities

Bucket elevators can handle various types of coal, including different sizes, densities, and moisture content. They are adaptable to handle both fine coal particles and larger coal chunks, providing flexibility in coal handling operations.

Reliable and durable

Properly designed and maintained bucket elevators offer reliable and long-lasting performance. They are built to withstand the harsh operating conditions of coal handling environments, ensuring minimal downtime and maintenance costs.

Coal bucket elevators can be integrated with other equipment to achieve efficient coal transportation and handling. Here are some common ways to integrate devices:

1. Coal storage equipment: Bucket elevators are usually used in conjunction with coal storage equipment (such as coal bunkers and coal piles). It can vertically lift coal from storage areas to where it is needed, such as coal-fired boilers, coal processing equipment or loading points.

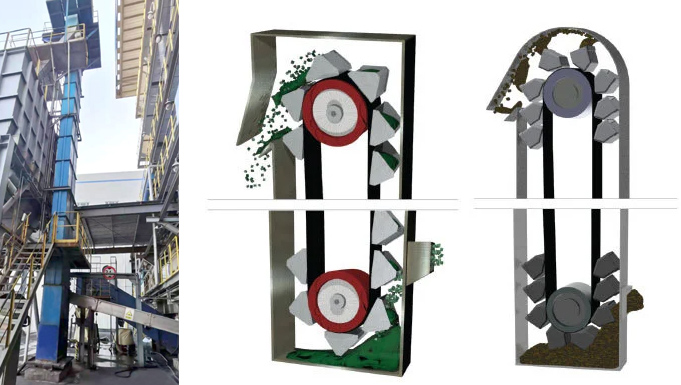

2. Coal crushing and screening equipment: Bucket elevators can be integrated with coal crushers, vibrating screens and other equipment to transport raw coal after crushing and screening. It lifts the crushed coal to the next processing stage or storage area.

3. Coal washing equipment: During the coal washing process, bucket elevators can be integrated with washing equipment (such as cyclones, heavy media separators) to transport the washed coal to storage areas or other processing equipment.

4. Conveyor belt system: The bucket elevator can be integrated with the conveyor belt system to realize continuous transportation of coal. It can unload coal from the top of the elevator onto the conveyor belt, and then the conveyor belt system will transport the coal horizontally to the target location.

5. Coal loading equipment: Bucket elevators can be integrated with coal loading equipment (such as loading buckets and conveyor belts) to unload coal from the elevator to the loading equipment to achieve fast and efficient loading operations.

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

Coal bucket elevators are commonly integrated into larger conveyor systems to facilitate the vertical movement of coal between different conveyor lines or processing stages. The integration of a coal bucket elevator into a conveyor system involves several key steps and considerations:

1.System Design: The integration begins with the overall design of the conveyor system, taking into account the specific requirements of the coal handling process. The layout, flow rates, and transfer points between conveyors are carefully planned to ensure a smooth material flow.

2.Feeding Conveyor: A feeding conveyor is typically positioned at the bottom of the coal bucket elevator to receive coal from an upstream conveyor or transfer point. This conveyor transfers the coal horizontally to the loading point of the bucket elevator.

3.Loading Point: At the loading point, the coal is fed into the buckets or cups of the bucket elevator. The loading mechanism can vary depending on the system design, such as direct loading, chute feeding, or controlled feeding through gates or valves.

4.Discharge Point: At the discharge point of the bucket elevator, the coal is transferred to another conveyor or processing stage. This could be a horizontal conveyor, a storage facility, or a feeding system for boilers, furnaces, or kilns, depending on the application.

5.Transfer Points: Transfer points between the bucket elevator and other conveyors are critical to ensure a seamless material flow. Proper transition components, such as chute designs, skirting, and sealing systems, are used to minimize spillage, dust emissions, and material degradation during transfer.

Thermal Power Plant

The thermal power plant uses coal bucket elevators to transport coal from coal bunkers to coal-fired boilers. The bucket elevator's efficient delivery ensures continuity of fuel supply while reducing the need for manual handling. This increases power plant productivity and ensures an accurate supply of coal.

Coal Mine

An underground coal mine uses coal bucket elevators to transport coal from the mining area to surface loading points. The vertical conveying capability and adaptability of the bucket elevator enable coal to be transported from underground to the surface quickly and safely, improving the production capacity of the coal mine and reducing risks during the transportation process.

Coal Processing Plant

The coal processing plant uses coal bucket elevators to transport washed coal from the washing equipment to storage areas. The integration of the bucket elevator allows the washed coal to be lifted to the storage area quickly and efficiently, ensuring the smooth progress of the subsequent processing stages.

Xinxiang Dahan is a professional coal bucket elevator manufacturer. As a leading supplier, they are committed to providing high-quality, reliable equipment solutions to the coal industry. Xinxiang Dahan's coal bucket elevators have efficient vertical transportation capabilities, flexible adaptability and advanced safety features, helping customers improve production efficiency, reduce labor intensity, and ensure safe and efficient coal transportation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.