Used for conveying wood chips, bark, sawdust, biological waste, etc. between storage silos in sawmills, using the cover to transport bulk goods in a sealed and low-dust manner

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 100mm-1250mm Length: 2-70 meters

Capacity: 458m³/h

Feeding rate: 244m³/h

Speed: 20-150 rpm

Conveying angle: 0-90 degrees

Application: For conveying sawdust and bark in sawmills

Commitment:

Sawdust screw conveyor is mainly used for wood processing line or biomass wood chip pellet production line to transport broken wood, such as sawdust, sawdust, etc. The product can be lifted from the automatic feeding equipment to the storage bin in the shortest time, and enter the next process. The conveying is uniform and fast, and the sealing structure solves the problem that a large amount of dust will be generated when conveying wood chips by traditional conveyors.

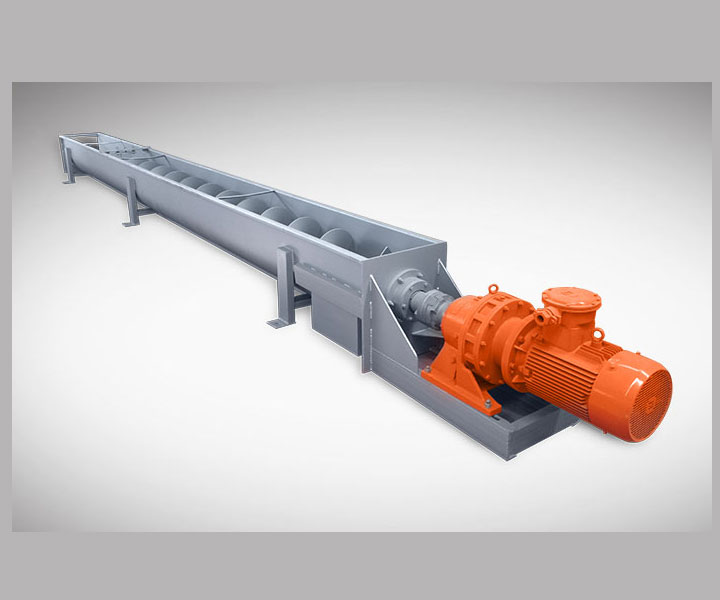

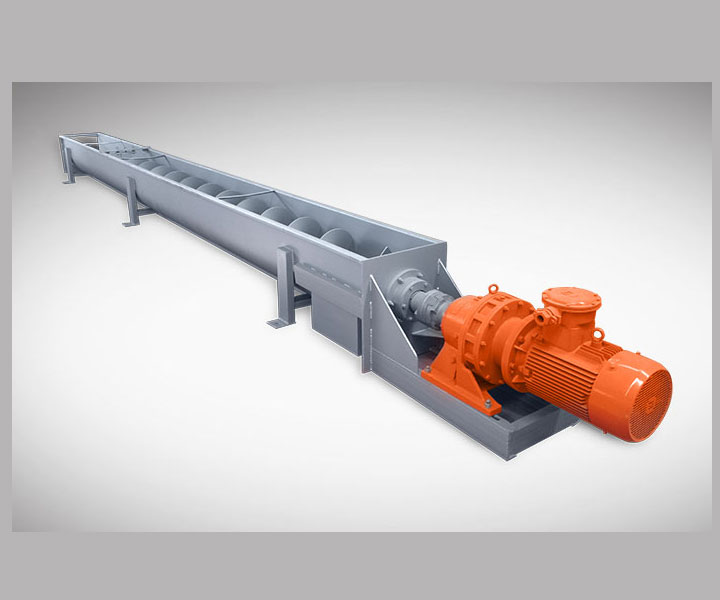

1. Horizontal Sawdust Screw Conveyor

Convey Sawdust to the designated place in the horizontal direction, and multiple inlet and outlet designs can be made.

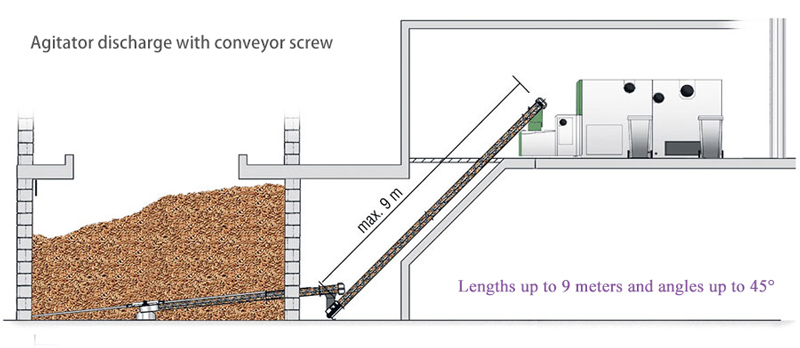

2. Tilt the Sawdust Screw Conveyor

It is usually used between 0-45°. If the inclination angle is too large, the efficiency loss caused by the angle needs to be compensated by increasing the power of the machine and increasing the torque.

3. Vertical Sawdust Screw Conveyor

The highest vertical lifting height is 8m. If vertical design is required, please connect a short horizontal screw at the feed inlet to ensure that Sawdust has enough upward lifting power.

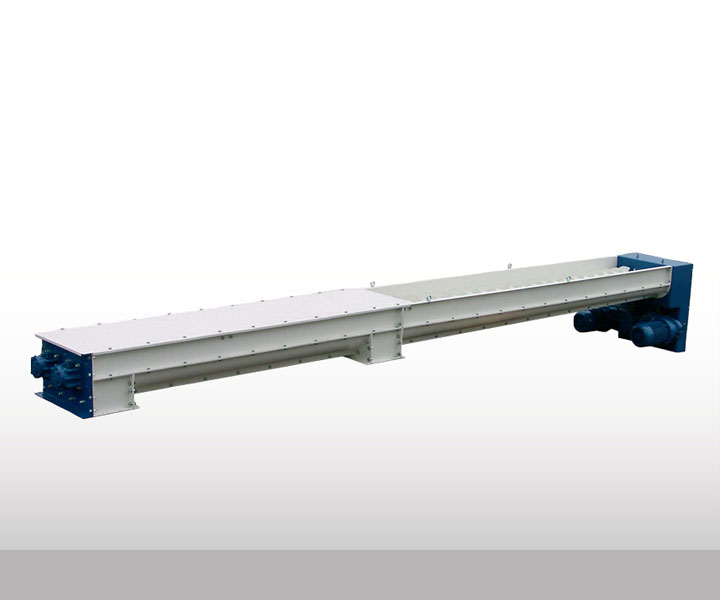

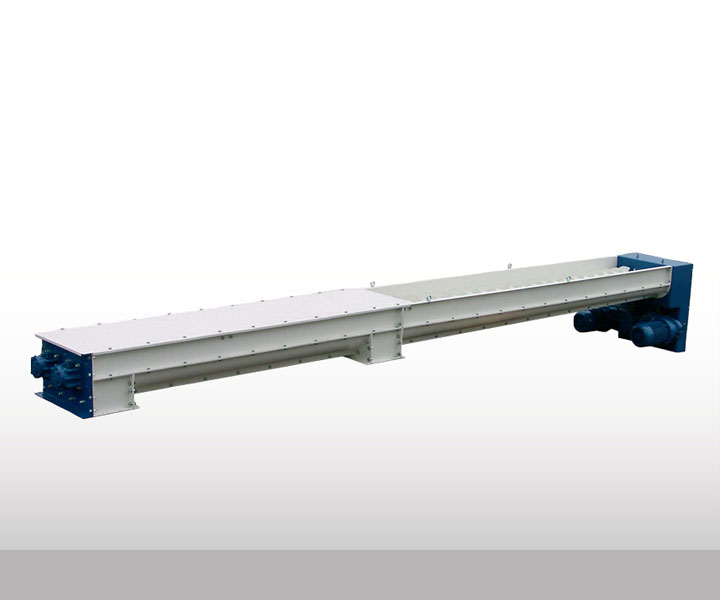

4. Shaftless Sawdust Screw Conveyor

The design of the screw without a central shaft can provide more space for Sawdust transportation, but it will inevitably lead to weakening of power, so please do not use the shaftless Sawdust Screw Conveyor for large inclination angle transportation of more than 15°.

5. Two-axis Sawdust Screw Conveyor

The conveying capacity is increased by 1.5-2 times, and it has a stronger driving force and stirring ability for Sawdust, and it is not easy to be blocked, but the conveying speed is slower.

In wood processing, it is necessary to use screw conveyors to transport the crushed wood raw materials, which is convenient for subsequent processing operations. The traditional screw conveyor will generate a lot of dust when conveying the crushed wood. When the wood flows out from the discharge port, it will cause great harm to the body of the staff and cause pollution to the environment. Therefore, we propose a screw conveyor for wood processing, which solves the problem of In the prior art, when the traditional screw conveyor conveys the crushed wood, a large amount of dust will be generated, and it will flow out together with the wood when it is discharged from the discharge port, which will cause great harm to the body of the staff. , It will also cause technical problems of pollution to the environment.

Applied materials: bark, chips, shavings, sawdust, chips, etc.

1. First, design a silo for the customer. The capacity is twenty cubic meters. All silos are equipped with silo wall vibrators and critical value alarms. The main function of the silo wall vibrator is to ensure the normal feeding of the silo. The function of the critical value alarm is to send out an alarm when the sawdust falls to the designated position, and inform the customer that they can continue to feed.

2. Secondly, at the outlet of the silo. Install a uniform feeding screw conveyor. The sawdust screw conveyor is equipped with a speed control switch, which can effectively control the feeding speed of the silo. To achieve the purpose of uniform feeding.

Workflow: Sawdust is loaded into the screw conveyor and continuously pushed by the helical blade welded on the rotating screw. Sawdust is in the delivery pipe groove, driven by the blade and the subsequent Sawdust, and continues to advance to the discharge point.

1. Sawdust is characterized by toughness and light specific gravity, and it is easy to get stuck during the conveying process. The screw conveyor adopts the design of variable diameter and variable pitch to prevent the phenomenon of broken shaft due to material accumulation.

2. Sawdust is relatively tough and easy to jam, so the length should not be too long, generally controlled within 7 meters, and it is not suitable to add a hanger in the middle to make it a single root.

3. Equipped with speed control switch. It can effectively control the feeding speed of the silo. To achieve the purpose of uniform feeding.

4. The sealed structure prevents the wood from producing a lot of dust during transportation, avoiding great harm to the staff and polluting the environment.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

1. The channel tank and cover are made of 304 stainless steel to prevent corrosion caused by steam inflow during the process. Screws, drive shafts and couplings are sized for the application with torque ratings well in excess of the drive's full motor torque. Inspection ports are included on each bolted coupling for easy access and inspection according to the preventive maintenance schedule.

2. The groove end of the separator provides a space between the groove end and the drive unit. The isolation space allows loose material to fall without contaminating the drive unit. To ensure that no fugitive material can escape, a KWS split gland seal was installed. The KWS Split Gland Seal is fully adjustable with replaceable graphite rope packing and provides a much better seal than traditional lip seals.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.