Loading and unloading of quartz sand in storage or transport containers for transfer of quartz sand from storage silo hoppers to transport vessels such as trucks, rail cars or barges

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Spiral direct: 100-1250mm

Length: 2-70 meters

Delivery capacity: 143 cubic meters per hour

Tilt angle: 0-60 degrees

Pitch: 100-630mm

Spiral speed: 13-140r/min

Power: 3-74KW

Application: transfer of quartz sand from shipping containers to storage facilities for further processing or use

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

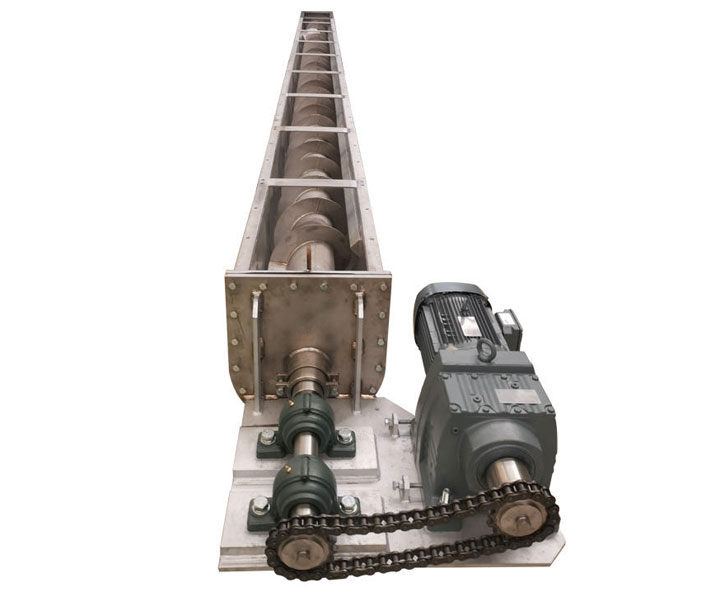

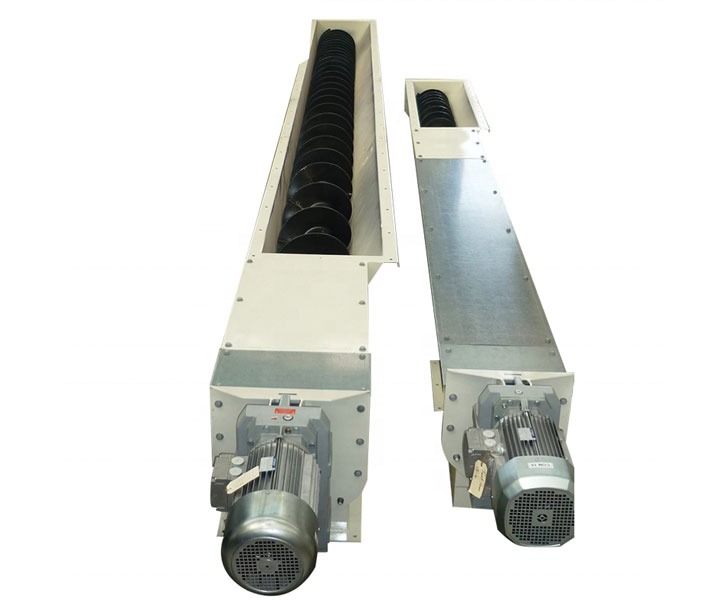

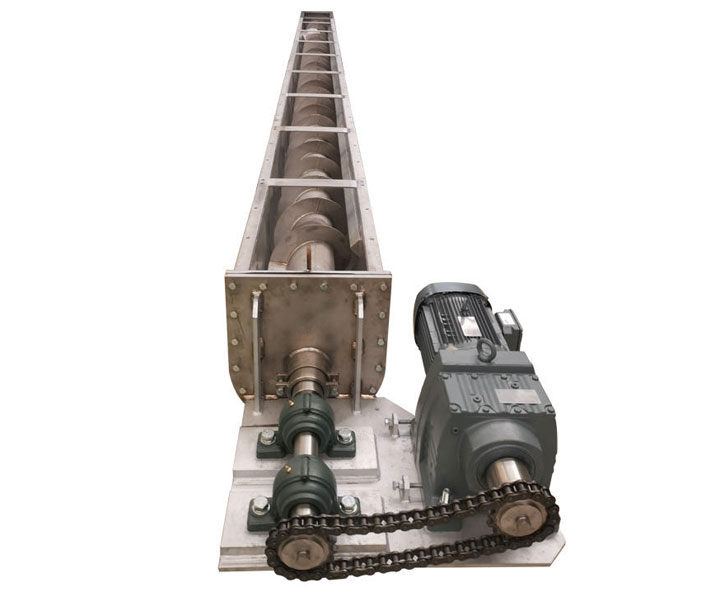

Quartz sand screw conveyor is used in foundries to store and measure quartz sand, and can also be used for vertical feeding of quartz powder storage tanks. Due to the high density and abrasiveness of quartz sand, the screw shaft and screw of the quartz sand screw conveyor The blades are made of high manganese steel, which has better wear resistance. Sturdy and not easily deformed or damaged.

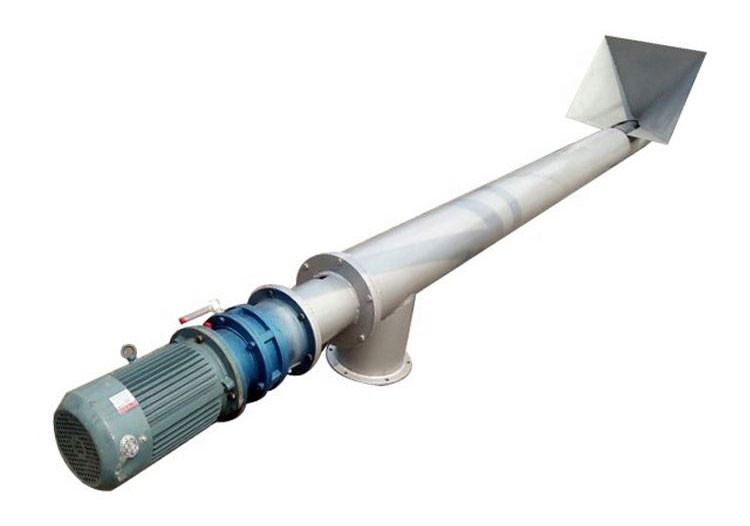

At the same time, the sealed tube design means that there will be no dust, which means that the quartz sand is more in line with environmental protection requirements during the transportation process, and at the same time ensures a good production environment.

Quartz sand screw conveyor is used to transfer products from each hopper, silo or bulk bag discharger to a buffer hopper, and then let them all pass through a sealed conveyor into the mixing chamber of the factory, suitable for many industries Quartz sand transportation and Processing, including glass manufacturing, foundries, construction, water treatment and chemical processing. , the following is the practical application of quartz sand screw conveyor

1. Loading and unloading: screw conveyors are used to transport quartz sand from storage bins or hoppers to transport containers such as trucks, rail cars or barges. The screw conveyor is located below the storage container and the sand is fed into the conveyor by gravity. A screw conveyor then transports the sand to a transport ship where it is unloaded.

2. Conveying between processing stages: Screw conveyors can be used to convey quartz sand between different stages of a processing plant, for example from crushing stage to screening stage. Screw conveyors can be designed in different configurations, including inclined or horizontal, to meet specific processing requirements.

3. Mixing and blending: the screw conveyor can be used for mixing and blending of different types of quartz sand or adding other additives or materials.

4. Screening and classification: The screw conveyor can transport the quartz sand to the screening machine or classifier, and sort the quartz sand into particles of different sizes and shapes.

5. Storage and recovery: The screw conveyor can transport the quartz sand to the storage silo or hopper, where it is stored until further processing or use is required. Screw conveyors can also be used to recover sand from storage bins or hoppers for further processing or use.

1. The conveying capacity can reach 458 cubic meters per hour, which can be automatically conveyed 24 hours a day to meet the production needs of quartz sand.

2. The screw shaft is made of manganese steel, and the screw is 8mm thicker, which minimizes the wear and tear of the quartz sand on the screw, and has a longer service life.

3. The long-distance transportation of 2-70 meters by a single machine can realize the connection and use of multiple conveyors, and the conveying direction can be designed horizontally, inclined and vertically.

4. The shell is made of seamless steel pipe, which can realize the whole process of sealed transportation of quartz sand and avoid dust.

Project: Conveying Quartz sand in Stone Plant

Customer need: Our customer owns a stone processing plant and needs to purchase a screw conveyor to convey the ground Quartz sand. There are multiple Quartz sand storage bins, which require multiple feed ports and one discharge port. The machine needs to work 14 hours/day, the maximum conveying capacity is 3000kg/h, occasionally there will be a small amount of conveying, and the factory has an inclination angle not greater than 10°.

Our design: First of all, for the consideration of transportation sanitation and efficiency, we chose the Quartz sand screw conveyor with tubular design. We confirmed its material density to the customer, and according to the characteristics of strong abrasiveness of the material, we specially coated the screw Layer spraying to reduce maintenance costs and prolong service life. In addition, in order to adapt to the uncertain delivery volume, it is necessary to choose an adjustable speed motor.

Quartz sand screw conveyor features:

1. The throughput can realize the production situation of 0.8t/h-3t/h

2. Environmentally friendly and safe tubular seal design

3. Coating makes the machine use longer

4. Use adjustable speed high-quality motor

Project: Conveying Aggregate in Building Material Factory

Customer need: Fill the mixer with relatively uneven fine aggregate particles with a diameter of 0.16-5mm. The use time is not fixed. The single delivery volume is about 60m³/h, and it needs to be delivered at an inclined angle of 50°.

Our design: Only a small Quartz sand screw conveyor can complete the work. In order to ensure the smoothness of material transportation, we choose to design variable pitch for the screw, and increase the silo to facilitate receiving aggregates. Since the 50° inclination is to compensate for the loss of efficiency, Choose a larger power motor, and at the same time, because the conveying aggregate is more abrasive, the spiral blades are cold-rolled.

Quartz sand screw conveyor features:

1. Variable pitch design to avoid blockage

2. High-power motor with sufficient power

3. Increasing the silo is more convenient for feeding and has a certain storage function

4. The hardness of the cold-rolled blade is higher

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Quartz sand screw conveyors usually consist of a trough or tube containing a helical blade coiled around a shaft, either driven from one or both ends, or a "shaftless screw" driven from only one end.

Trough: It is a circular or U-shaped container in which the material is enclosed during conveying. Channels are usually fabricated from sheet steel and are available in standard lengths. If longer slots are required, a greater number of such units are connected together.

Spiral shaft: it consists of a long narrow steel plate of certain thickness twisted and wound in a helical shape, these standard threads are welded to the central shaft, alternatively, the conveying element is suspended along the length of the trough with the help of a hanger .

Drive end and discharge end: Also known as the box, at the drive end, the shaft is connected to the bevel gear, the power is transmitted to the screw blade through the shaft, and the shaft rotates around the shaft and remains close to the bottom of the tank. Feed is typically added through the feed port, providing a uniform flow of material. At the discharge end, an open chute or open bottom chute is used to receive material.

The screw conveying equipment used for the transportation of bulk sand and gravel particles can perform mobile work and can be used in production lines such as stone factories and foundries.

The quartz sand screw conveyor can also be used for conveying other types of sand, such as:

1. Silica sand: Silica sand is a kind of sand with high silica content, which is often used in the production of glass, ceramics and refractory materials. Silica sand screw conveyors can be used to convey sand from storage bins or hoppers to processing equipment.

2. Foundry Sand: Foundry sand is used in the casting process in foundries and can be made from a variety of materials including silica, chromite, and zircon. Foundry sand screw conveyors can be used to convey sand to foundry machines or storage bins or hoppers.

3. Frac Sand: Frac sand is a special type of sand used in hydraulic fracturing operations in the oil and gas industry. Frac sand screw conveyors can be used to transport sand from storage bins or hoppers to transport vessels such as trucks, rail cars or barges.

4. Construction Sand: Construction sand is used in various applications such as building foundations, landscaping and road construction. Construction sand screw conveyors can be used to convey sand from storage silos or hoppers to construction sites.

| Sand Type | Use | Practical Application |

| Silica sand | Conveys sand from storage bins or hoppers to processing equipment. | Glass manufacturing plants transport sand from storage bins to glass furnaces, foundries transport sand to casting machines or storage bins or hoppers, water treatment plants use silica sand as a filter medium to remove impurities in water, and use screw conveyors to transport sand Conveying to filtration systems, used in construction applications such as building foundations and road construction, screw conveyors can be used to transport sand from storage silos or hoppers to construction sites. |

| Foundry sand | Conveying sand to casting machines or storage bins or hoppers. | In sand preparation, it is used to transport sand and other materials to sand making equipment such as sand mixer, in sand mold cooling, it is used to transport hot sand to cooling equipment such as sand cooler, in sand recovery, it is used to transport waste sand from casting machine Transport to sand recycling equipment such as sand separator. |

| Frac sand | Used to transport sand from storage bins or hoppers to transport vessels such as trucks, rail cars or barges. | In sand storage and transportation, it is used to transport fracturing sand from storage bins or hoppers to transport ships such as trucks, railcars or barges; in loading and unloading, it is used to transfer fracturing sand between transportation containers and storage bins or hoppers; In sand processing, frac sand is conveyed to processing equipment such as dryers or screens, in mixing, it is used to mix different types of frac sand, or to mix other additives or materials. |

| Construction sand | Can be used to transport sand from storage silos or hoppers to construction sites. | Conveying construction sand from storage silos or hoppers to construction sites, for transferring construction sand between transport containers and storage silos or hoppers, for conveying sand to processing equipment such as washing machines or screens, for mixing Different types of construction sand or mixed with other additives or materials. |

We are a professional manufacturer of quartz sand screw conveyors. We have many years of production experience and technical advantages, and our products sell well at home and abroad. Our R&D and manufacturing teams have always maintained excellent features such as leading technology, reliable quality, simple operation, and convenient maintenance. The product range is complete and the specifications and models are diversified, which can meet different customer needs. We will, as always, adhere to the service concept of "quality first, customer first", and provide every customer with high-quality products and perfect services. Welcome customers to inquire!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.