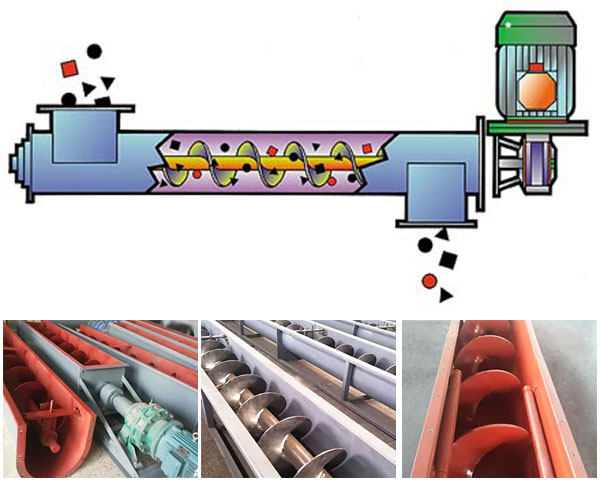

Horizontal conveying of powder, granules and small block materials can simultaneously complete various process requirements such as conveying, stirring and mixing

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 100-800mm

Length: 3~70 meters

Output: 9-140t/h

Material: carbon steel/stainless steel

Motor power: 1.6-73kw

Application: Used for powdery, granular and small block materials in various industries for conveying, cooling, mixing, compacting and loading.

Commitment:

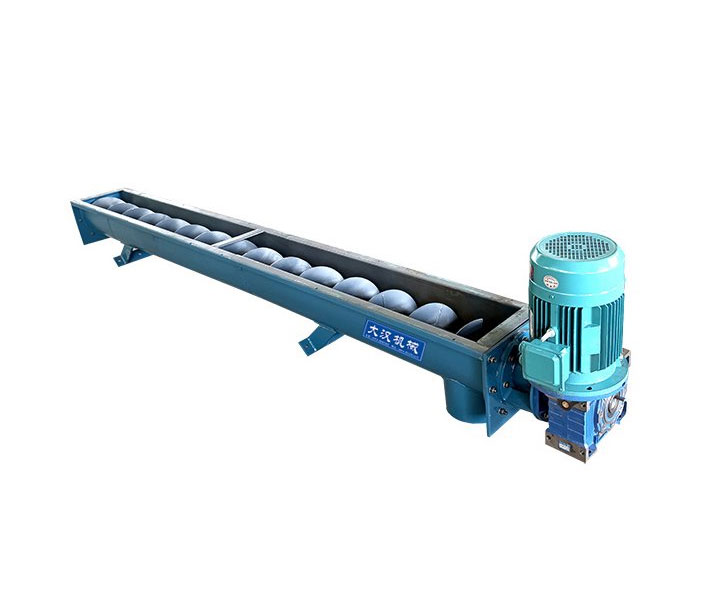

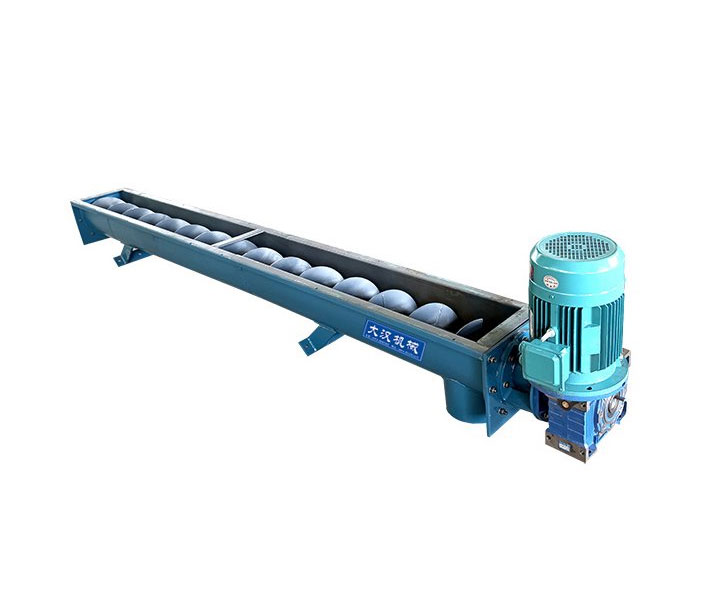

Horizontal screw conveyor is used to convey powder, granules and small block materials horizontally, and can complete various process requirements such as conveying, stirring and mixing at the same time. When too many materials enter, there will be no jamming phenomenon, which is convenient for multi-point loading and unloading. Horizontal screw conveyor models are: 200, 250, 300, 400, 500, 600 and other 6 specifications, suitable for small-scale, short-distance conveying of powder/granule/small block materials, conveying length 10-20 meters, the longest can be Up to 60 meters, the conveying capacity is 9-438 cubic meters per hour, and the inlet/outlet is connected by flange/bag, which has good sealing performance and can prevent dust.

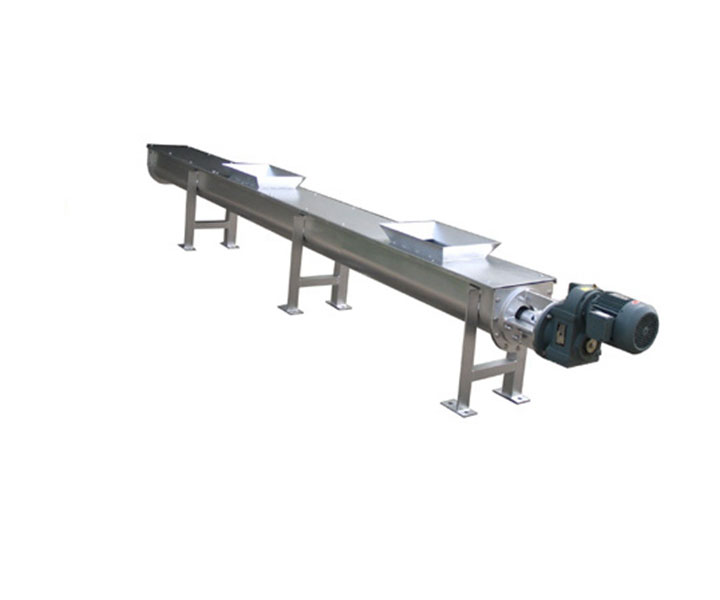

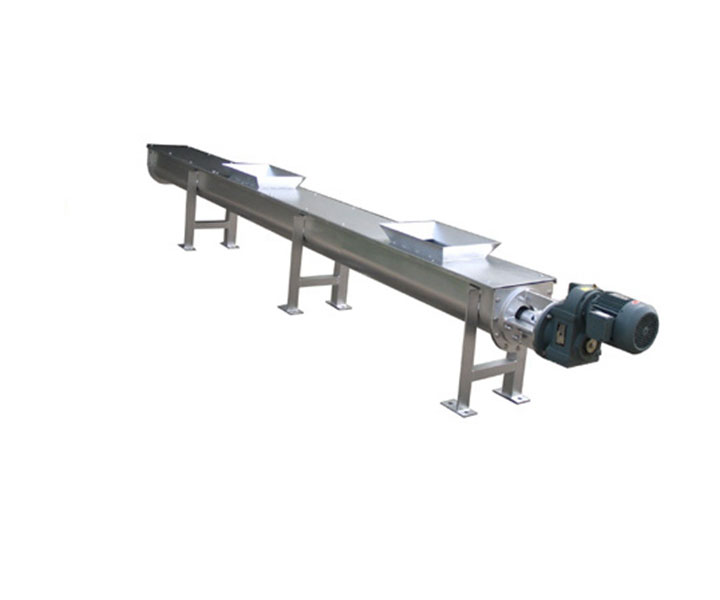

| Type | Horizontal tube screw conveyor | Horizontal U type screw conveyor | Horizontal shaftless screw conveyor | Stainless steel horizontal screw conveyor |

| Image |  |

|

|

|

| > Features | The pipe diameter ranges from 100mm to 1250mm, and the speed is high to ensure fast and uniform delivery. | Small range conveying, single point or multiple points feeding and discharging, detachable cover, easy to maintain | Without a shaft, no intermediate or end bearings are required, suitable for viscous and entangled materials, such as sludge, biomass, garbage, etc. | 304/316L stainless steel material, resistant to high temperature of 200℃, resistant to acid and alkali corrosion, not easy to rust, in line with food, medical and health regulations |

| Capacity | 142m³/h | 134m³/h | 458m³/h | 142m³/h |

| Length | 2-70 meters | 2-70 meters | 2-70 meters | 2-70 meters |

| ZPS-1500 |

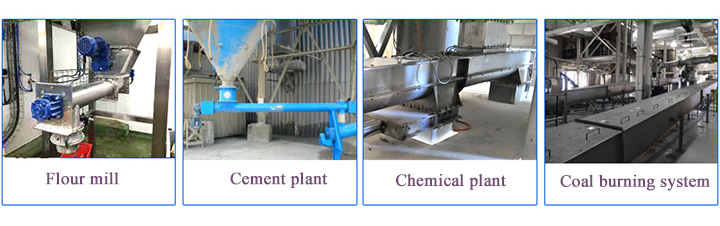

Horizontal screw conveyor is suitable for conveying powdery, granular and small block materials with small inclination angle and small range. It is widely used in grain, chemical industry, building materials, metallurgy, mining, electric power and other departments. The following are several common application occasions:

Sewage treatment plant: It can be used in sewage treatment plants to transport solid debris, such as coarse and fine grid cleaning machine slag and sludge dewatering machine mud cake and other materials.

Garbage treatment plant: Kitchen waste or domestic waste generated by household kitchens, restaurants, restaurants, canteens, markets and other industries, stainless steel can prevent damage to the machine due to corrosive materials.

Industrial waste treatment: such as boiler coal feeding system, solid waste incineration, etc.

Cement batching plant: It is used for conveying powder materials such as cement and fly ash. During the conveying process, the materials can also be mixed and stirred to prevent concrete agglomeration.

Conveying grain

Conveying sludge

Conveying clay

1. High conveying efficiency

It can be conveyed horizontally or obliquely, the conveying inclination angle is less than 20°, the conveying length of a single machine can reach 70 meters, and the conveying capacity can reach 458 cubic meters per hour.s

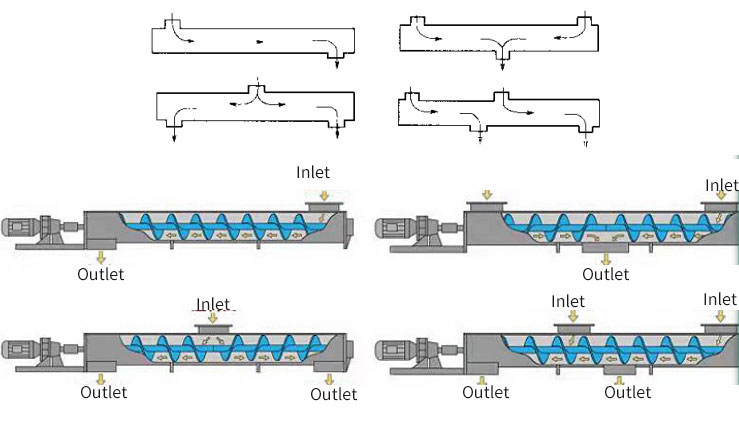

2. Flexible layout

The conveying direction can be reversed, and it can also be conveyed to the opposite two directions at the same time. According to the process requirements, it can meet the multi-point feeding and discharging.

3. No dust

The overall sealing is rigorous, which can prevent dust from flying and reduce environmental pollution.

4.Easy to operate

It is convenient for loading and unloading at multiple points, and can complete the mixing, stirring or cooling functions during the conveying process.

The horizontal screw conveyor is made of a rotating shaft with a spiral piece that rotates in a closed trough. When the material is added to the fixed trough, due to the gravity of the material and the friction between the machine trough, it will accumulate on the machine trough. The material in the lower part of the tank does not rotate with the spiral body, but only moves forward under the push of the rotating spiral blade, just like the non-rotating nut doing translational movement along the rotating screw rod, so as to achieve the purpose of conveying materials.

The horizontal screw conveyor is composed of a driving device, a head assembly, a casing, a shaftless screw body, a trough liner, a material inlet, a material outlet, a cover (when necessary), a base, etc.

1. Driving device: Cycloidal pin wheel reducer or shaft-mounted hard-toothed gear reducer is used. When designing, the driving device should be installed at the end of the discharge port as much as possible, so that the spiral body is in a tensioned state during operation.

2. The head is equipped with a thrust bearing, which can withstand the axial force generated when conveying materials.

3. Chassis: The casing is U-shaped or O-shaped, with a rainproof cover on the top, made of stainless steel, carbon steel or glass fiber reinforced plastic.

4. Spiral body: Shaft or shaftless design is optional, and the material is stainless steel or carbon steel.

5. Lining plate of tank body: the material is wear-resistant plastic plate or rubber plate or cast stone plate, etc.

6. Inlet and outlet: There are two types of square and round. Generally, the form of inlet and outlet is determined by the user.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

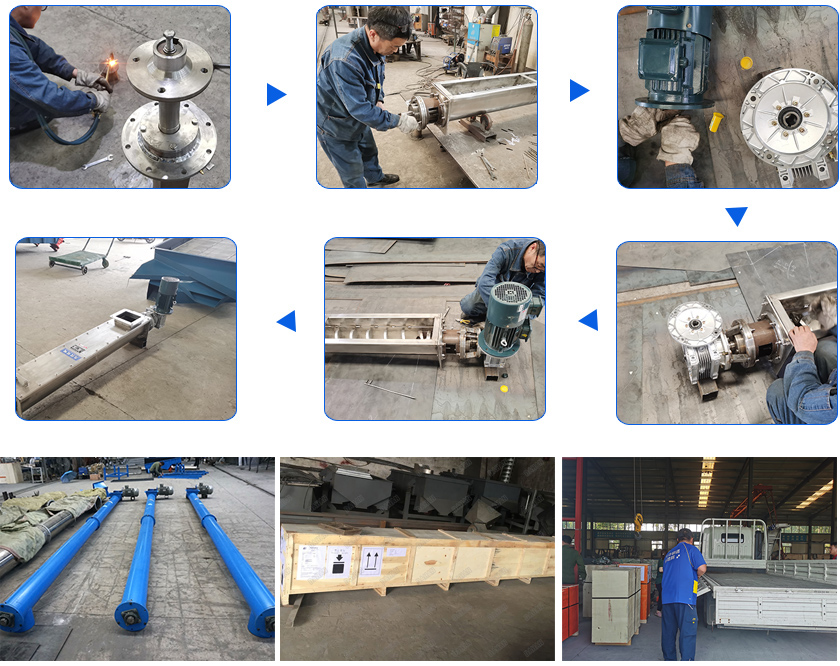

Xinxiang Dahan has 15 years of experience in producing horizontal screw conveyors. It has a complete range of models and can provide free selection and drawing design. It has various lathes, milling machines, installation workshops, spraying workshops, warehouses and other processing workshops, as well as various cutting machines and bending machines. Machine and polishing machine processing equipment, provide one-stop service from design, drawing, processing, assembly, painting, quality inspection, test machine, packaging and delivery, provide 12-month quality warranty, and provide maintenance services for life.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.