The horizontal screw conveyor is suitable for conveying bulk materials from one process point to another in the horizontal direction. It can be loaded and unloaded at multiple points. The conveying length is generally 10-20 meters, and the length can reach 60 meters. The following will introduce you The structure and working principle of horizontal screw conveyor.

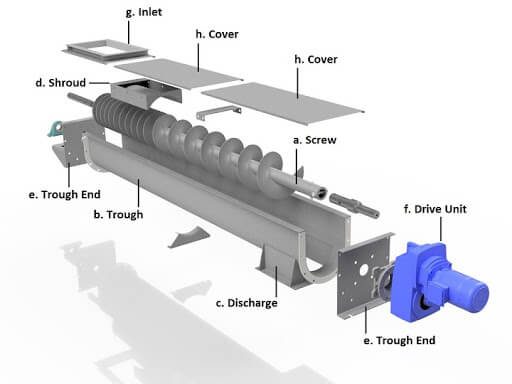

The level is mainly composed of driving device, intermediate bearing, screw shaft, screw body, screw blade, head, middle, tail, feeding and discharging device and other components.

1. Driving device: It is composed of a motor and a deceleration deceleration unit. The driving motor is 380V, three-phase, 50Hz, the protection class is IP55 (outdoor type), and the insulation class is F class. The gear reducer has high torque, low noise and no oil leakage.

2. Intermediate suspension bearings: divided into two types:

①Head bearing: Thrust bearing: bear the axial force generated by the resistance of the conveyed material, and place it in front of the material.

②Intermediate bearing: split sliding bearing, used to support the screw shaft.

3. Spiral shaft: There are two types: shaft and shaftless, carbon steel or stainless steel can be selected.

When the material is put into the fixed trough, due to the material's own weight and the friction between the troughs, it will accumulate on the machine trough, and the material will move forward under the push of the rotating helical blade, so as to achieve the horizontal conveying.

The above is the introduction to the structure and working principle of the horizontal screw conveyor. There are 200, 250, 300, 400, 500, 600 and other types of horizontal screw conveyors, which are used for small, short Distance conveying, single-point feeding, single-point unloading, multi-point feeding, and multi-point unloading can be selected according to requirements.

|

Diameter (mm) |

150 | 200 | 250 | 300 | 400 | 500 |

| pulverized coal |

Speed (r/min) |

112 | 100 | 900 | 80 | 70 |

|

Delivery capacity (m3/h) |

8 | 14 | 24 | 34 | 64 | |

| cement |

Speed (r/min) |

90 | 75 | 75 | 60 | 60 |

|

Delivery capacity (m3/h) |

3.5 | 6.7 | 13.3 | 8.3 | 43.5 |

This article aims to introduce you to the structure and principle of the horizontal screw conveyor. If you are interested in the product or have any questions about the product, you can click: https://www.dahanmachine.com/product-center/SCREW-CONVEYOR.html to view the product introduction page.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.