The screw conveyor can be divided into a Shaftless screw conveyor and a shafted screw conveyor in the conveying form. The working principle and function of the shafted screw conveyor and the shaftless screw conveyor are basically the same, and they are all used for material conveying equipment. Different types of screw conveyors have different advantages and have their own unique advantages. The following will summarize some of the differences:

Compared with the traditional shafted screw conveyor, the shaftless screw conveyor adopts a central shaftless design and a U-shaped cross section.

The shafted screw conveyor has a spiral shaft support in the middle, and adopts a tubular or U-shaped cross section. The shaftless screw conveyor adopts wear-resistant lining, and the spiral blade is thicker than the shafted screw conveyor.

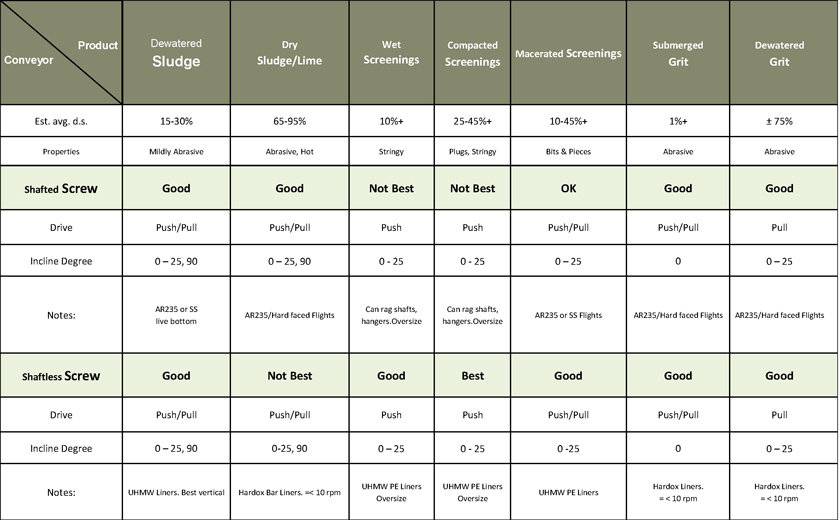

The conveying angle of the shaftless screw conveyor can't exceed 30 degrees, otherwise it will easily lead to material falling off when conveying materials.

The shafted screw conveyor has a screw shaft support, the conveying angle can exceed 30 degrees, and even the vertical conveying state can be achieved. In addition, Dahan Company can customize according to the actual needs of users.

Since the shaftless screw conveyor adopts the design without a central shaft, it is suitable for conveying materials: sludge, domestic garbage, grid slag, etc., which are viscous, entangled materials and block materials.

The shafted screw conveyor is suitable for conveying materials: powder, small particle materials, etc. If the viscous material such as sludge is transported, it will stick to the inner tube shaft and the blade, and the block material will easily cause blockage and affect the transportation efficiency. At the same time, it also caused a certain loss to the machine.

Because the shaftless screw conveyor adopts no shaft, the material is not easy to be blocked, and the discharge port is not blocked, so it can run at a lower speed, smooth transmission and reduce energy consumption. The torque is large and the conveying capacity is large. The conveying distance is long, and the single machine can transport up to 60 meters. According to the needs of users, it can be installed in multi-stage series, conveying materials over long distances, and the conveying capacity is 1.5 times that of the traditional shafted screw conveyor of the same diameter.

The above is a comparative analysis of the difference between the shafted screw conveyor and the shaftless screw conveyor, I hope to help you!

Dahan manufacturer produces different types of screw conveyors. There is always one that interests you. If you want to know more information, please click on the online chat on the right and I will be happy to answer your questions. Your consultation is very welcome.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.