Conveying solid particles or granular materials from one location to another

![]()

![]()

![]()

Price:$760.00-$20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 100-1250mm

Angle of inclination: 0-90 degree

Contact part material: Mild steel,SUS304 or SUS316L

Hopper Size: 100L, 230L Feeding rate: 244m³/h

Loading capacity: 250kg

Conveying height: ≤8 meters

Power Supply: 380V/220V 50-60Hz Power: 1.5-5.5KW

Application: Provide a reliable and efficient solution for moving pellets over long distances, and can be customized to meet specific material handling requirements, suitable for conveying pellets such as plastic pellets, wood pellets, feed pellets, etc.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Particle screw conveyor is a mechanical device used to move granular materials in a controlled manner. It consists of a helical screw blade contained within a tube or trough, which rotates to push particles along the conveyor's length.

This type of conveyor is commonly employed in industries such as agriculture, food processing, mining, and construction for transporting materials like grains, seeds, powders, and bulk solids efficiently and continuously. The design of the screw conveyor allows for precise control over the flow rate and direction of the particles being conveyed, making it a versatile and essential component in various industrial processes.

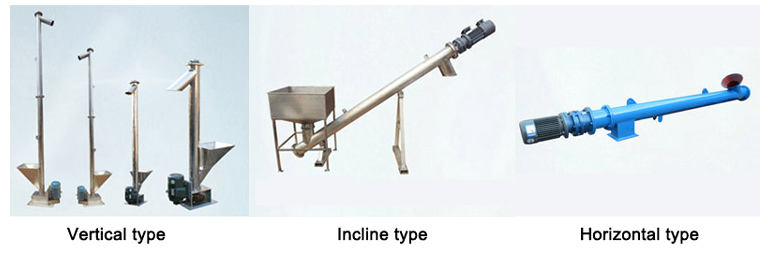

Particle screw conveyor can be specially designed to suit specific needs or with applicable options. Here are some common types:

1. According to the conveying angle classification: particle screw conveyors can be divided into horizontal, inclined and vertical particle screw conveyors. The angle of horizontal particle screw conveyors is usually between 0° and 15°, the angle of inclined screw conveyors is usually between 15° and 45°, and the angle of vertical screw conveyors is close to 90°.

2. Material type selection: Particle screw conveyors can be divided into carbon steel particle screw conveyors and stainless steel particle screw conveyors. For some special particles, it may be necessary to use wear-resistant, corrosion-resistant or special coating materials to extend the service life.

3. Spiral design type: Depending on the particle characteristics and transportation requirements, different shapes of spiral designs can be selected. Common spiral designs include solid spirals, spirals with cutting edges, adjustable spirals, etc.

Application of particle screw conveyor

Particle screw conveyors are widely used in grain processing, chemical industry, building materials, metallurgy, mining and other fields for horizontal, inclined or vertical transportation of granular materials, such as grains, cement, ores, fertilizers, etc.

The following are the applications of particle screw conveyors in various particles:

| Conveying products | Application | Conveying products | Application |

| Sugar | Uniform delivery of sugar to silos | Gravel | Handling and transportation |

| Salt | Can be used to transfer salt from storage tanks to processing equipment such as mixers or dryers | Quartz sand | It can be used for the handling and transportation of quartz sand in various industries such as glass manufacturing, foundries and construction. |

| Grains | Can be used to feed grain into processing equipment such as mixers or extruders. | Activated carbon | Can be used to load activated carbon into adsorption vessels or unload it from bulk bags or drums. |

| Seed | Used to transfer seed from storage bins to processing equipment such as seed cleaners, sorters or packers. | Sand | Can be used to transport sand from one location to another, for example from a storage silo to a processing plant. |

| Animal food | Used to move feed from storage tanks to processing equipment such as mixers or pelletizers | Aggregate | Can be used to load aggregate into trucks or rail cars, or unload it from bulk bags or hoppers. |

| Plastic pellets | Used to move plastic pellets from storage tanks to processing equipment such as extruders or injection molding machines | Coal | Can be used in processes that require cooling or heating of coal. Screws can be jacketed or insulated to allow circulation of cooling or heating fluids./td> |

Here are the key functions of a particle screw conveyor:

1.Conveying: The primary function of a particle screw conveyor is to transport particles or granular materials from one point to another.

2.Feeding: Particle screw conveyors can be utilized as a feeding mechanism, delivering materials into various processing equipment or production lines.

3.Discharging: Particle screw conveyors efficiently discharge materials at the desired location or into subsequent processing equipment.

4.Storage and Handling: It can facilitate the vertical or inclined movement of materials, enabling efficient storage and handling in silos, hoppers, or other storage vessels.

Screw Conveyor for Wheat Grains

Screw Conveyor for Wood Pellets

Efficient transportation

Granules, powders and other materials can be efficiently transported over short and long distances, reducing the need for manual handling or other forms of transportation.

Gentle handling

Granules can be handled gently, reducing the risk of product damage or degradation and maintaining the quality and value of the material.

Low maintenance

Requires minimal maintenance and can run continuously, reducing downtime and maintenance costs.

Cost-effectiveness

Cost effective to install and operate, providing a reliable and efficient solution for material handling and transportation.

Safety

Provides a safe, enclosed method of transporting materials that reduces the risk of spills, dust emissions, and other hazards associated with other modes of transport.

Customizable Design

Screw conveyors can be customized to suit specific applications and materials, with a choice of different sizes, shapes and materials of construction.

Particle screw conveyor pushes granular materials to be transported along the pipeline through the rotation of screw blades. The motor drives the screw shaft to rotate, and the screw blades push the particle materials from the inlet to the outlet, using centrifugal force to transport the materials forward. During the transportation process, the particle materials are pushed by the screw blades and restricted by the pipe wall to achieve efficient and continuous transportation.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

As a multifunctional conveying equipment, particle screw conveyor plays an important role in various industries: it is used for raw material transportation and processing in the food industry, ensuring the safe transportation of chemicals in the chemical industry, improving production efficiency in the building materials industry, storing and transporting grains and feed in the agricultural field, and transporting ore and coal in the mining field. It improves material handling efficiency in the logistics field, helping various industries to achieve automated and efficient particle material transportation, reduce costs and improve production efficiency.

For Conveyoring Salt

Particle screw conveyors are used to transport salt particles efficiently. Its special design and options ensure a reliable delivery process, prevent particle clogging, and provide flexible adjustment and control to meet the needs of salt particle delivery.

For Conveyoring Slag

Particle screw conveyors can be used to transport slag pellets efficiently. Its special design and options ensure a reliable conveying process, prevent particle clogging, and provide flexible adjustment and control to meet the needs of slag conveying.

For Conveyoring Soybeans

The vertical screw conveyor is suitable for transporting granular materials such as soybeans, with a vertical height of up to 3 meters. Whether it is from the storage warehouse to the processing equipment, or from the production line to the packaging area, the vertical screw conveyor can stably transport the soybeans to the required location.

Dahan Granule Screw Conveyor Manufacturer has many years of production experience and technical accumulation. Our granule screw conveyors are widely used in mining, chemical, building materials, grain processing and other industries, and are stable and efficient in conveying granular materials. Our products have the advantages of simple structure, reliable operation and convenient maintenance, and are well received by customers. We provide a variety of specifications and models of granule screw conveyors to meet the needs of different customers. The price is generally $760.00-$20,000.00/Set. We are committed to providing customers with high-quality products and services. You are welcome to contact us at any time. We will wholeheartedly provide you with detailed product information and quotations to meet your production needs.

WhatsApp:+86 15236742901

Address:China,Yanjin county forest park gate to the west 1000 meters north road.