Ensuring a seamless and efficient material handling process for powdered sugar in the food processing industry

![]()

![]()

Price:$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Product specification: TD160-400

Belt Type: Rubber Belt or Reinforced Belt

Particle size: 4-180 mm

Production capacity: 0.65-69.6m³/h

Lifting height: 40 meters

Temperature can reach 200°C

Equipment material: carbon steel, stainless steel

Application range: chemical industry, metallurgy, building materials, mining and other industries

Application materials: limestone, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartz stone, bentonite, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Powdered sugar screw conveyor is a screw conveyor specially designed for conveying powdered sugar in the food processing industry. It is used to convey powdered sugar from one location to another. Ingredients are steadily supplied to downstream equipment such as mixers, shakers and packaging machines.

Powdered sugar augers are typically made of food-grade stainless steel and are designed to handle the delicate nature of powdered sugar. Conveyors are designed with dust covers and seals to prevent the release of dust and other airborne particles during transport, which helps maintain a clean and safe work environment for plant operators. It can be designed in different lengths and configurations to fit the available plant space and convey sugar through different process stages. Conveyors can be inclined or horizontal, depending on the specific requirements of the application. Conveyors can also be designed with variable speed drives to control the flow rate of sugar and prevent overloading or underfeeding of downstream equipment.

The role of the powdered sugar screw conveyor is to convey powdered sugar from one location to another in a food processing plant. The Powdered Sugar Screw Conveyor is designed to handle the delicate nature of powdered sugar, a fine powder made from granulated sugar, commonly used in the baking and confectionery industries.

Here are some specific features of the powdered sugar screw conveyor:

1. Feeding downstream equipment: used to feed downstream equipment such as mixers, mixers, packaging machines, etc. Conveyor belts ensure a steady and precise flow of powdered sugar to these machines, which is crucial for consistent product quality.

2. Dust Control: Dust-proof design helps prevent the release of dust and other airborne particles during transport. This helps maintain a clean and safe working environment for plant operators.

3. Material handling: designed to deal with the fragility of powdered sugar, which is easily damaged or degraded during transportation. The conveyor is designed with gentle handling to ensure that the sugar is not damaged during transport.

4. Conveying: used in food processing plants to transport powdered sugar from one place to another. Conveyors can be designed in different lengths and configurations to fit the available plant space and convey sugar at different stages of the process.

Material Handling Design

Powdered Sugar Screw Conveyors are designed to handle the fragility of powdered sugar, preventing it from being damaged or degraded during transport. The conveyor is designed with gentle handling features such as low screw speeds and minimal clearance between the screw and the trough to ensure that the sugar is not damaged during transport.

Hygienic design

Made of food-grade stainless steel, it meets food safety standards. The conveyor is designed for easy disassembly and cleaning, with a smooth surface and no crevices where bacteria can easily grow. This helps maintain a hygienic processing environment.

Dustproof design

Dust-tight design with lid and seal to prevent release of dust and other airborne particles during transport. This helps maintain a clean and safe working environment for plant operators.

Variable speed drive

Variable speed drives can be designed to control sugar flow and prevent overloading or underfeeding of downstream equipment. The speed of the screw can be adjusted to meet the specific requirements of the application.

Systematize

It can be flexibly matched with screening machines, mixers and other equipment, and can also complete mixing, stirring, loosening, heating and cooling processes during the process of conveying powdered sugar.

Flexibility

Can be designed in different lengths and configurations to fit the available plant space and convey sugar through different process stages. Conveyors can be inclined or horizontal, depending on the specific requirements of the application.

The working principle of the powdered sugar screw conveyor is to put the powdered sugar into the barrel of the conveyor, and drive the powdered sugar forward through the rotation of the spiral blade. When the powdered sugar enters the screw conveyor, the screw blades will gradually push the powdered sugar to the outlet, and pass through the sieve to filter out the unqualified particles.

Conveying granulated sugar and powdered sugar:

Powdered sugar screw conveyor is suitable for conveying superfine powdered sugar and granulated sugar, and other similar granular materials. During the conveying process, attention should be paid to controlling the flow and speed of the powdered sugar to ensure the quality and particle size of the powdered sugar.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

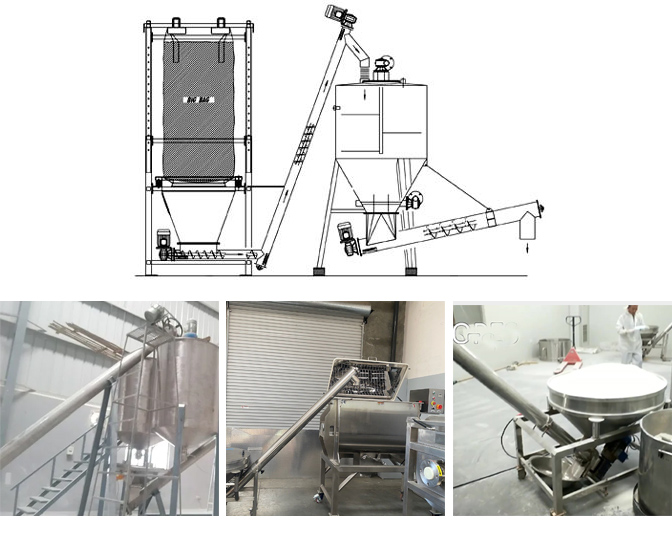

The powdered sugar screw conveyor can be combined with a sieving machine, packing machine or mixing machine to form a feeding system:

1. With sieving machine: The combination of powdered sugar screw conveyor and sieving machine helps to ensure a high-quality product by removing any impurities that may affect the taste or texture of the final product. It also helps reduce the risk of downstream equipment becoming clogged or damaged by foreign objects, thereby increasing the efficiency of the material handling process.

2. With packaging machine: it can transport powdered sugar from the processing equipment to the packaging machine. The screw conveyor can be designed to feed the powdered sugar into the packaging machine at a consistent rate to ensure the packaging process is efficient and reliable, the combination of the powdered sugar screw conveyor and the packaging machine helps by maintaining the integrity of the powdered sugar throughout the packaging process to ensure high quality products. It also helps in increasing the efficiency of the material handling process by automating the packaging process and reducing the need for manual labor.

3. With mixer: It can convey powdered sugar from processing equipment to sieving mixer, the combination of powdered sugar screw conveyor and sieving mixer helps to ensure that powdered sugar is mixed with other dry ingredients and removes any impurities High-quality products. It also helps in increasing the efficiency of the material handling process by automating the mixing process and reducing the need for manual labor.

1. Regular maintenance and cleaning of the conveyor: For long-term use of the conveyor, regular maintenance and cleaning are required to ensure its normal operation and prolong its service life.

2. Control the conveying speed: By adjusting the feeding amount and the rotating speed of the spiral blade, the conveying speed is controlled to ensure the quality and flow of the powdered sugar conveyed.

3. Anti-blocking of conveying pipelines: For powdered sugar with high moisture absorption and easy caking, appropriate pipelines should be used, and anti-blocking treatment should be carried out on the conveying pipelines.

4. Control temperature: For powdered sugar that is susceptible to moisture, it is necessary to control the temperature and humidity during the transportation process so as not to affect its quality.

In a word, the powdered sugar screw conveyor is an efficient and stable sugar transmission equipment, which is suitable for the transportation of powdered sugar and granulated sugar. During use, attention should be paid to controlling the flow and speed of powdered sugar, and the conveyor should be maintained and cleaned regularly to ensure its normal operation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.