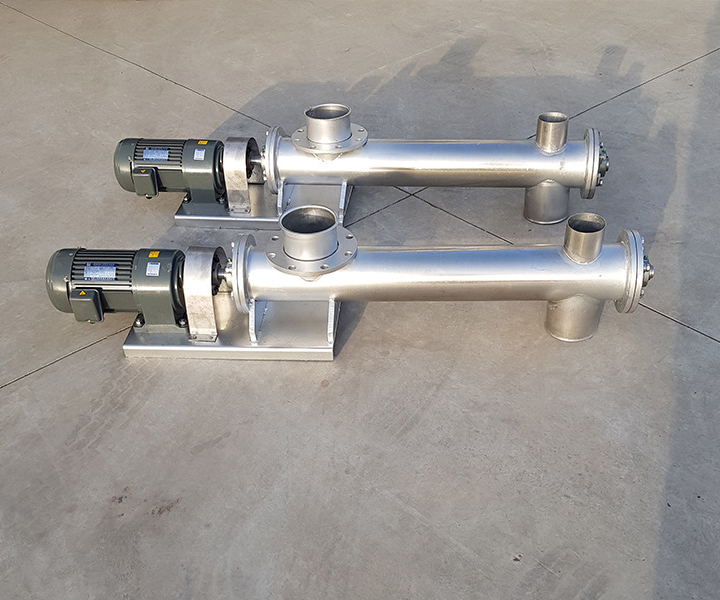

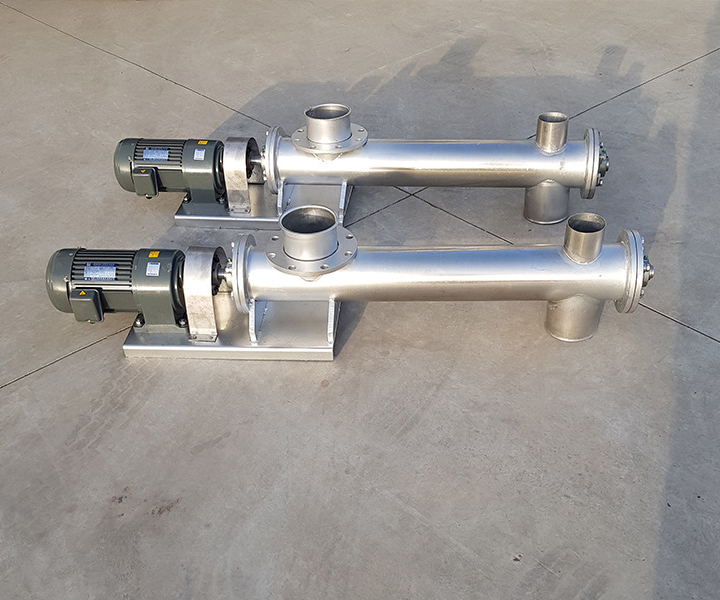

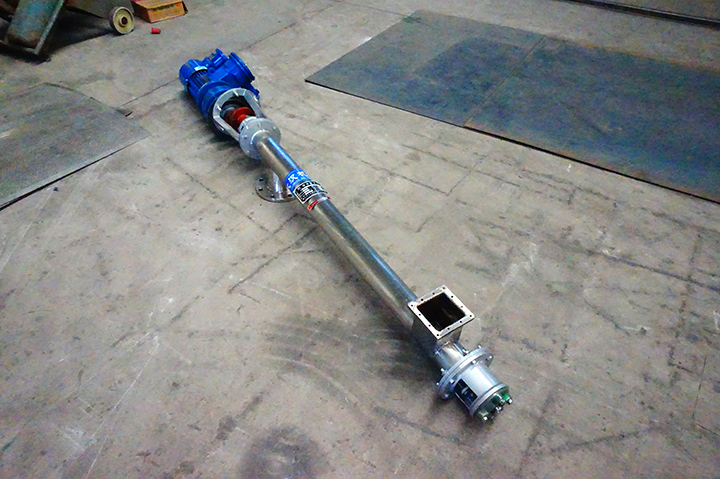

Specially designed for small feed rates and laboratories, mainly installed below the silo or main screw feeder as a feeding device

![]()

![]()

Price:$300.00-$1,000.00/Set

Consult now and enjoy a 10% discount

Screw diameter: 100mm、125mm、159mm

Length: 100mm-2000mm

Delivery capacity: 0.01-1000 kg/h

Speed: 90-140 rpm

Application: Uniform and continuous feeding and unloading of small batches of powder and granules for laboratories and small batching plants

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

The specification of Micro auger feeder is based on the feeding volume per hour (feeding volume): the general feeding volume ranges from 0.001 kg/h to 1000 kg/h (for those with more than 1000 kg/h, please use other screw feeders of our company) Feeder), the length of auger feede (center distance between inlet and outlet) is generally 100mm-2000mm. Discharge method: There are two kinds of vertical discharge and horizontal discharge. Users can freely choose according to their requirements. The specific specifications and length can be customized according to user requirements. The hopper can be prepared according to user requirements.

| Types | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 |

| Rotating speed(r/min) | 100 | 120 | 90 | 90 | 75 | 75 |

| Capacity Qφ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 |

| Power Pd 1=10m(kw) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 |

Specification only for your reference, size variable as per customer's request. Note: Please use other types of screw conveyors of our company for those larger than 1000 kg/h. |

||||||

Micro auger feeders are specifically designed to provide maximum precision at minimum feed rates, which makes these feeders ideal for use in the chemical and pharmaceutical processing industries. , unique design features ensure accurate feeding of high value ingredients at rates as low as 0.01-1000 kg/hr while minimizing residual material remaining in the feeder. Typically used in the production of chemicals and pharmaceuticals or any process that requires precise delivery of small quantities.

1. The diameter of the screw is 100mm-159mm, the length (centre distance between inlet and outlet) is generally 100mm-2000mm, and the conveying capacity is 0.01kg/h-1000kg/h. It is specially designed for small feeding speed and laboratory applications.

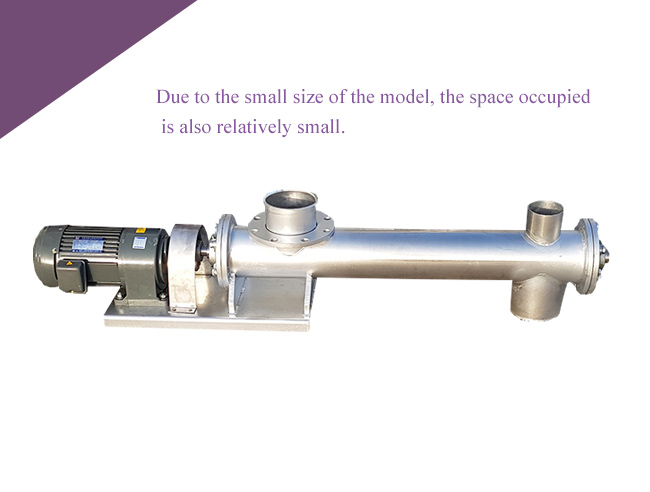

2. Small diameter, small footprint, suitable for particularly narrow feeding environment.

3. The speed is fast, and the conveying products are more uniform, smooth and fast.

4. Adding a stirrer can eliminate material blockage in the hopper section.

Micro auger feeder feeds the material evenly to the next sequence. When the motor in the drive device drives the reducer and then the coupling transmits it to the screw shaft, the material enters from the feed port and discharges the material from the body under the action of the screw blade.

1. In order to adapt to different materials and feeding speeds, there are 3 types of screws to choose from to meet the feeding volume requirements of various laboratories.

2. The design of the feeding trough combined with the bottom-driven vertical agitator can almost eliminate product residue.

3. The sealed structure can prevent external dust from entering the machine and prevent product from spilling out.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.