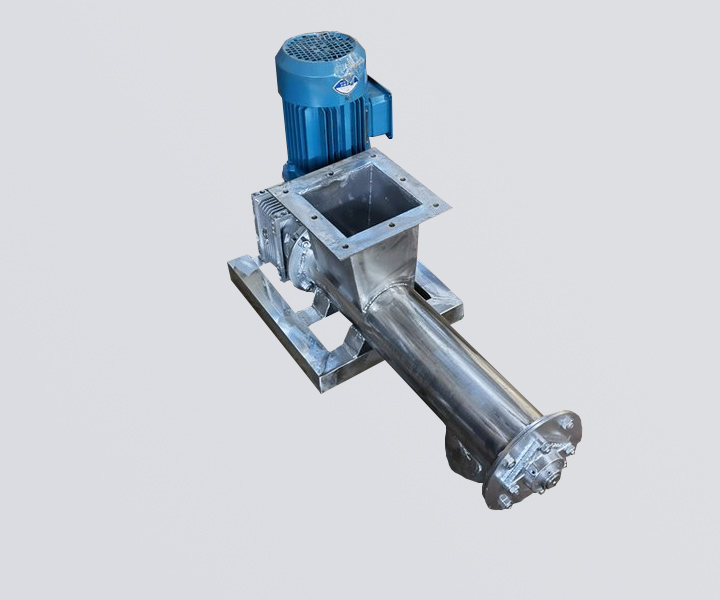

Micro screw feeder

Micro screw feeder Carbon steel micro screw feeder

Carbon steel micro screw feeder Stainless steel micro screw feeder

Stainless steel micro screw feeder Micro twin screw feeder

Micro twin screw feeder Micro screw feeder with vibro sifter

Micro screw feeder with vibro sifter

Commonly used in the production of chemicals and pharmaceuticals or any process that requires precise small quantities of additives.

![]()

![]()

Price:$300.00-$1,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 114mm, 159mm, 160mm, 250mm, 315mm

Capacity: 0.001 kg/h-1000 kg/h

Length: 100mm-2000mm

Feeding speed: 32 g/h

Accuracy: 0.1 kg (up to 0.01 kg with special screws)

Material: carbon steel/stainless steel

Weight: 25-45kg

Application: Used to provide maximum accuracy with minimum feed rates, which makes these feeders ideal for use in the chemical and pharmaceutical processing industries.

Commitment:

The micro screw feeder is specially designed for small feed rates and laboratory applications. It can reliably and accurately feed a variety of powders and granular materials on a very small base, and feed accurately at speeds as low as 32g/h. With minimal residual material in the feeder, it is ideal for the production of chemicals and pharmaceuticals or any process that requires precise small quantities of additives.

Micro screw feeder screw diameter is 100mm, 125mm, 139mm, the general feeding volume is from 0.01kg/hour to 1000kg/hour (please choose our other screw feeders for more than 1000kg/hour), the length of the feeder (in and out The distance from the center of the mouth) is generally 100mm-2000mm, which is specially used for uniform and continuous feeding and unloading of small batches of powdery and granular materials.

Micro screw feeders have a wide range of applications in industries that require precise and accurate feeding of small quantities of materials. Here are some examples of industries and applications where micro screw feeders are commonly used:

Pharmaceuticals: Used to feed small amounts of active pharmaceutical ingredients (API) and other materials into tablet presses, capsule filling machines, and other pharmaceutical processing equipment.

Food processing: It is used to feed a small amount of flavoring, coloring and other additives into food processing equipment.

Electronics manufacturing: Used to feed small quantities of solder paste, flux, and other materials into automated soldering equipment.

Chemical processing: Used to feed small quantities of catalysts, additives, and other materials into chemical reactors and other processing equipment.

5Laboratory research: Used in laboratory research to dispense small quantities of powders and other materials for experiments and testing.

| Model | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 |

| Rotating speed(r/min) | 100 | 120 | 90 | 90 | 75 | 75 |

| Capacity Qφ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 |

| Power Pd 1=10m(kw) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 |

Specification only for your reference, size variable as per customer's request. Note: Please use other types of screw conveyors of our company for those larger than 1000 kg/h. |

||||||

Small feeding amount

The screw diameter is 114-159mm, and the feed rate is as low as 32 g/h, and the feeding rate is from 0.01 kg/h to 1000 kg/h.

High feeding accuracy

Minimum clearance between propeller and feed tube ensures high precision feeding, Accuracy: 0.1 kg (up to 0.01 kg with special screws).

Small footprint

Accurately feed a wide range of powders or granules in a very small footprint, ideal for laboratory applications.

Sealing system

The whole conveying work is carried out by bucket type in the pipeline, which avoids the pollution of dust to the environment.

Uniform delivery, not easy to jam

Small diameter screw, and low rotation speed, ensure fast and even product delivery.

Flexible layout

The inlet and outlet can be made into the required inclination angle according to the situation of the work site, and it can be connected and fixed with other supporting equipment.

Micro screw feeder for feeding perlite

Micro screw feeder for conveying sand

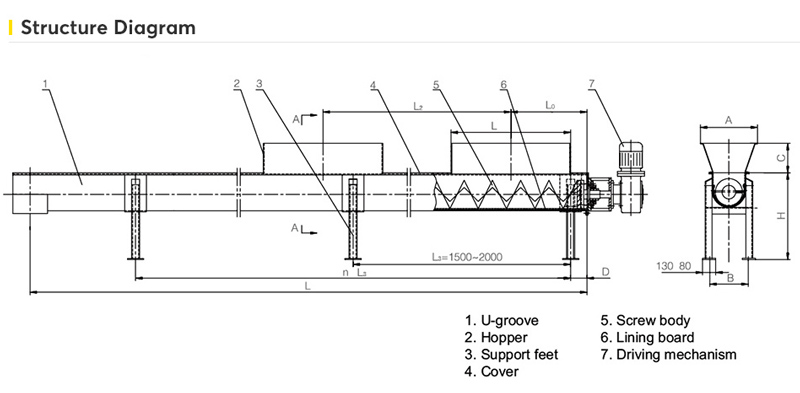

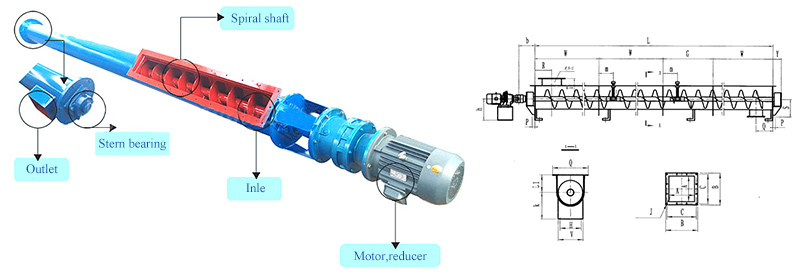

Micro screw feeder is a device that conveys materials by rotating the spiral blade. Its working principle is to use the motor to drive the spiral blade to rotate in the pipe or trough, generating thrust to continuously convey the material along the axis of the spiral blade.

Specific process:

Motor drive: The motor transmits power to the spiral blade through the reducer to make it rotate.

Material entry: The material enters the feeder through the feed port.

Spiral push: The rotating spiral blade pushes the material forward along the conveying pipe or trough.

Material output: The material is output through the discharge port to achieve continuous transportation.

| Model | W | A | B | C | D | N | Q | Y | L | K | R | S | P | O | H | V | J | T | G | L |

| LS100 | 2500 | 100 | 180 | 146 | 10 | 4 | 180 | 190 | 90 | 112 | 180 | 112 | 60 | 178 | 120 | 160 | 14 | 163 | 1500 2000 2500 |

3500-40000 |

| LS160 | 2500 | 160 | 240 | 206 | 10 | 4 | 200 | 190 | 112 | 150 | 200 | 150 | 60 | 270 | 120 | 160 | 14 | 190 | ||

| LS200 | 3000 | 200 | 300 | 256 | 14 | 8 | 225 | 112 | 180 | 225 | 180 | 308 | 160 | 200 | 14 | 212 | ||||

| LS250 | 3000 | 250 | 350 | 306 | 14 | 8 | 250 | 140 | 224 | 250 | 224 | 336 | 200 | 250 | 18 | 240 | 40000-80000 | |||

| LS315 | 3000 | 315 | 425 | 370 | 14 | 8 | 330 | 214 | 280 | 390 | 250 | 443 | 300 | 350 | 20 | 340 |

From the product aspect, the optional types of micro screw feeder

Micro screw feeders can be customized with a variety of options to meet the specific needs of different applications. Here are some common options available for micro screw feeders:

1. Hopper: A hopper can be installed to increase the capacity and provide buffer for the fed material.

2. Material level sensor: A material level sensor can be installed to monitor the amount of material in the feeder and adjust the screw speed accordingly.

3. Discharge valve: a discharge valve can be installed to control the material flow and prevent overfeeding or underfeeding.

4. Agitator: Agitator can be added to prevent material bridging or blockage.

5. Hoses: hoses can be added for easy connection to other processing equipment.

6. Special coatings or materials: Can be coated with or made of specific materials to handle corrosive or abrasive materials.

Micro inclined screw feeder

Features: Inclined installation, using gravity to transport materials to a higher position.

Advantages: Simple structure, small footprint, easy installation, suitable for small production lines or occasions with limited space.

Application scenarios: Suitable for conveying powders, granules and other materials to hoppers, mixers and other equipment, such as small packaging production lines, pharmaceutical production lines, food production lines, etc.

Micro vertical screw feeder

Features: Vertical installation, using the rotation of the screw shaft to push the material upward.

Advantages: Higher conveying height, larger conveying volume, suitable for higher material conveying.

Application scenarios: Suitable for conveying powders, granules, flakes and other materials to higher equipment, such as large packaging production lines, chemical production lines, metallurgical production lines, etc.

Dahan micro screw feeder has 15 years of production experience, providing one-stop service from design, drawing, processing, assembly, painting, quality inspection, test machine, packaging and delivery, etc. Its products cover a variety of models, which can be customized according to customer needs and are widely used in electronics, machinery, food and other industries. Dahan micro screw feeder is known for its compact structure, easy operation and stable performance. It uses high-quality materials and is durable. The manufacturer provides 12 months quality warranty and lifelong maintenance service, and has passed ISO9001 quality system certification and EU CE certification! The quality is guaranteed and you can use it with confidence.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.