Move powders, granules or sticky products from one point to another

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

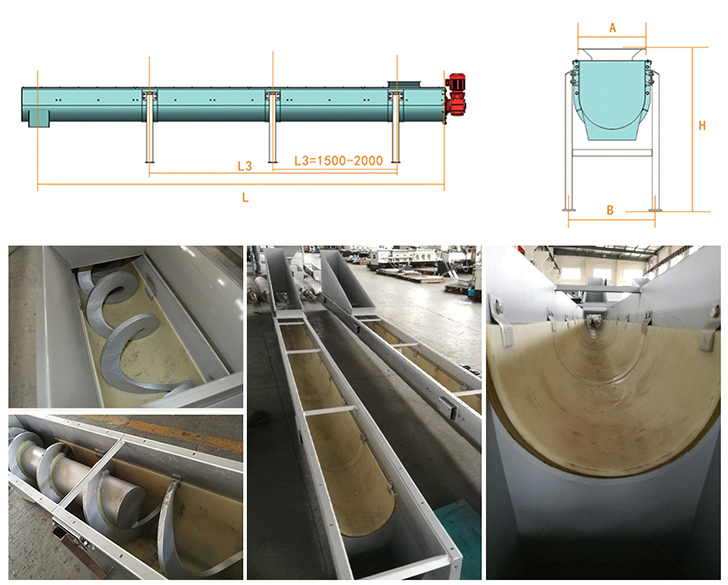

Diameter: 100mm-1250mm

Length: 2-70 meters

Capacity: 458m³/h

Speed: 20-150 rpm

Conveying angle: 0-90 degrees

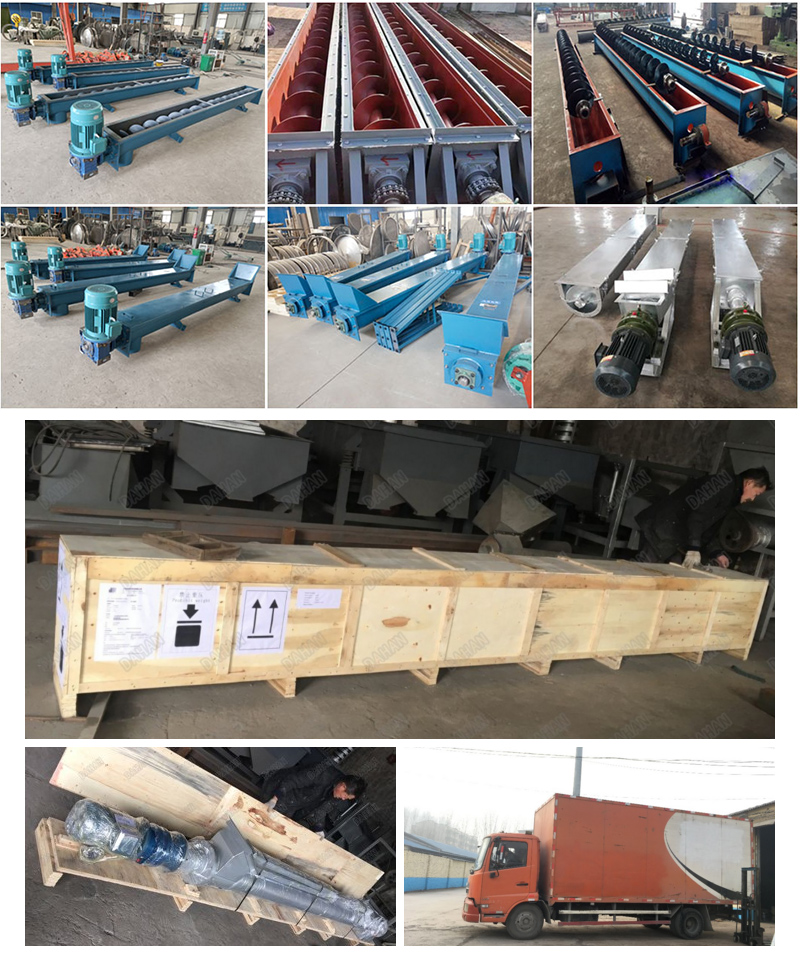

Material: carbon steel, stainless steel, plastic

Other Function: Cooling/Heat Resist/Anti Corrosion

Application: Move material from one point to another in a controlled and efficient manner. Screw conveyors are commonly used in a variety of industries, including agriculture, food processing, mining and construction, where materials need to be transported over long distances or between different stages of processing.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

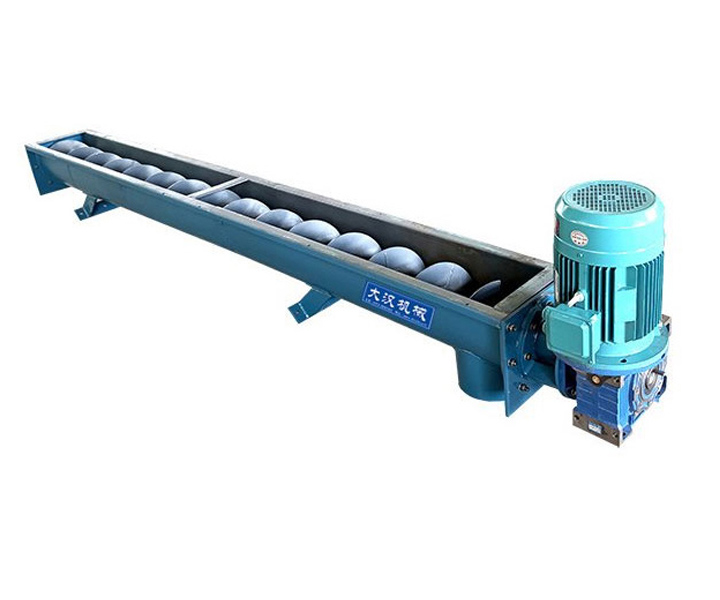

Helix conveyor, also known as a spiral conveyor or an auger conveyor, is a type of conveyor system that is designed to move materials in a circular path around a central shaft. The helix conveyor consists of a rotating screw or auger that is enclosed in a cylindrical casing or trough. As the screw rotates, it moves the material along the length of the trough, while also imparting a circular motion to the material.

Helix conveyors can be used for various applications, including the vertical transportation of bulk materials such as grains, powders, granules, and liquids. They are commonly used in industries such as agriculture, food processing, mining, chemical processing, and manufacturing.

Standard Helix Conveyor

This is the most common type of helix conveyor, consisting of a single screw or auger that is enclosed in a cylindrical casing or trough.

Double Helix Conveyor

It is designed with a double helix screw that has a ribbon-like flighting, allowing for more efficient movement of sticky or viscous materials.

Paddle Helix Conveyor

It is designed designed with paddles attached to the flighting of the screw, which helps to agitate and mix materials as they are conveyed.

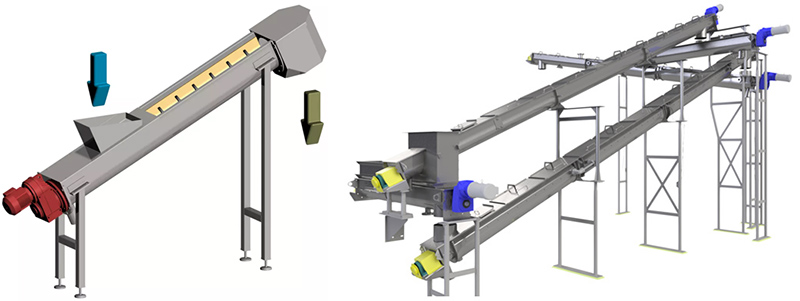

Flexible Helix Conveyor

This type of helix conveyor is designed with a flexible screw that can be easily bent or curved to accommodate tight spaces or complex layouts.

Shftless Helix Conveyor

Moving and conveying viscous products that are difficult to convey with conventional shafted screw conveyors in industries such as wastewater treatment, pulp.

Cooling Helix Conveyor

Usually consisting of a screw or auger enclosed in a jacketed groove, the water can be pre-cooled before entering the jacket, or it can be cooled during circulation.

Helix conveyors use the rotational motion of screw blades to transport materials along pipes. Here's how it works:

Material inlet: The material enters the screw cavity of the helix conveyor from the inlet.

Spiral blade movement: The motor drives the screw shaft to rotate, and the screw blades rotate accordingly, pushing the material forward.

Centrifugal force: The material is subjected to centrifugal force under the action of the screw blades and moves along the screw axis.

Conveying materials: The materials are gradually transported forward with the rotation of the screw blades, and finally discharged through the discharge port.

Efficient and reliable transportation

Designed to move material in a controlled and efficient manner, which helps increase productivity and reduce labor costs.

Can be used for multiple functions

It can be used to mix, heat or cool, lift and dewater materials, making it a versatile conveying system.

Versatility

A wide variety of materials can be handled, including powders, granules, and even liquids. They are commonly used in a variety of industries including agriculture, food processing, mining and construction.

Prevent material compaction

The circular motion of the helix conveyor helps prevent material settling or compaction, which can be a problem in other types of conveyors.

Customizable Design

Can be customized to meet the specific needs of the application, including the size and shape of the tank or housing, the diameter and pitch of the screw, and the type of material being conveyed.

Low maintenance cost

Maintenance costs are generally low, with few moving parts and minimal wear and tear. They require little lubrication and are easy to clean and maintain.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Helix conveyor diameter 100mm-1250mm, length 2-70m, material carbon steel, stainless steel, wear-resistant steel, heat-resistant steel, blade thickness 2-6mm, rotation speed 20-150/min, special specifications can be made according to customer needs.

The helix conveyor has a variety of customization options and can be tailored to the specific needs of the application. Some of the most common customization options include:

Tank or Housing Design: Tank or housing can be customized to meet the specific requirements of the application, including shape, size and material.

Screw Design: Screws can be customized based on factors such as the type of material being conveyed, the capacity and speed of the conveyor. The diameter, pitch and thread of the screw can be customized to meet the specific needs of the application.

Materials of Construction: Screw conveyors can be constructed in a variety of materials, including stainless steel, carbon steel, and other alloys, depending on the requirements of the application.

Drive Arrangement: Drive arrangements can be customized according to the layout and space constraints of the application, including vertical, horizontal and oblique arrangements.

Cooling or Heating Options: Can be designed with options for cooling or heating the conveyed material, depending on the requirements of the application.

Accessories: Various accessories such as hoppers, discharge doors and sensors can be added to enhance its functionality and performance.

Helix conveyor is a versatile and widely used conveyor system with many applications in different industries, the following are some of the most common applications including:

Agriculture: Used in agriculture to move grain, seeds, and other agricultural products from one location to another. They are also used in animal feed production, conveying feed to mixing and packaging equipment.

Food processing: Used in the food industry to convey food products such as powders, grains and spices between different processing stages including blending, blending and packaging.

Mining: Used in the mining industry to transport bulk materials such as coal, ore, and minerals from one location to another.

Chemical Processing: Used in the chemical industry to transport various types of chemicals, including powders, granules and liquids, between different processing stages.

Construction: Used in the construction industry to transport materials such as concrete, sand and gravel to and from construction sites.

Waste Management: Used in waste management to move waste and recycled materials such as paper, plastic and metal from one location to another.

Water Treatment: Used in water treatment plants to transport sludge, biosolids and other materials from the treatment process to the dewatering and disposal stages.

The price of the helix conveyor varies with its model, size, material, production process, manufacturer and other factors, and there is no fixed price. Generally speaking, the price of an ordinary model, small, low-material helix conveyor ranges from a few hundred dollars to a few thousand dollars; while a large, special material, high-performance helix conveyor can cost up to tens of thousands of dollars. Therefore, the purchase of helix conveyors needs to be fully considered according to actual needs, and manufacturers and products with reliable quality, excellent performance and reasonable prices should be selected.

Xinxiang Dahan helix conveyor manufacturer is a company specializing in manufacturing screw conveyors. They have extensive experience and expertise and are leaders in the design, manufacture and installation of screw conveyors. Their products are efficient, reliable and durable and are widely used in materials handling and handling applications. Xinxiang Dahan Helix Conveyor Manufacturer is committed to providing customers with customized solutions to meet the needs of different industries and applications, and to provide efficient and smooth material conveying solutions for customers' production processes.

WhatsApp:+86 15236742901

Address:China,Yanjin county forest park gate to the west 1000 meters north road.