Helix conveyors, also known as screw conveyors or auger conveyors, are available in a variety of models to suit different material handling needs.

1) GX type helix conveyor

The GX type helix conveyor is available in single-tube and double-tube forms, and is suitable for horizontal conveying where the inclination angle cannot exceed 20°. It can transport some lumpy (small lump materials) such as wheat, corn, soybeans and other grains.

Model: GX200, GX250, GX300, GX400, GX500, GX600

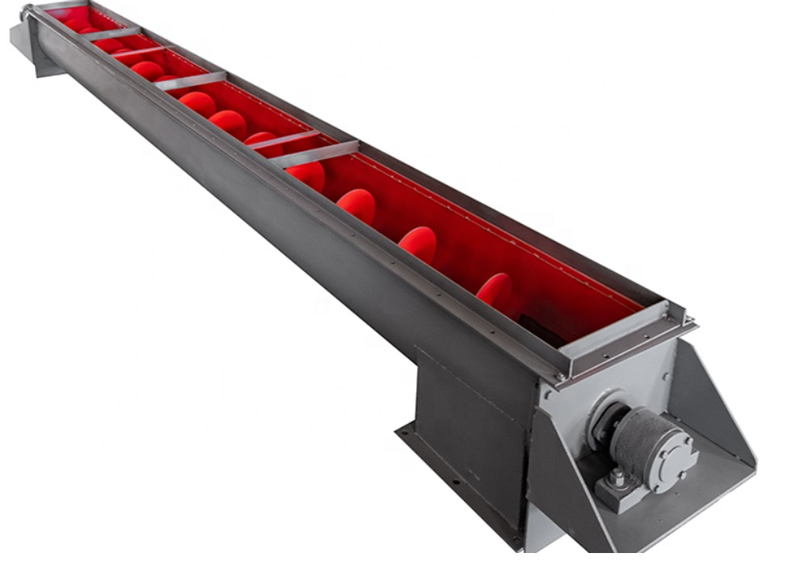

2) LS type helix conveyor

LS type helix conveyorLS is an improvement of GXhelix conveyor. The main improvement is the hanging bearing structure, which allows materials to pass more smoothly. Suitable for: transportation of materials in building materials, electric power, chemical industry, metallurgy, aluminum and magnesium, machinery and other industries. The conveying length of LS type helix conveyor can reach 70 meters.

Model: 100mm, 200mm, 250mm, 315mm, 400mm, 500mm, 600mm, etc.

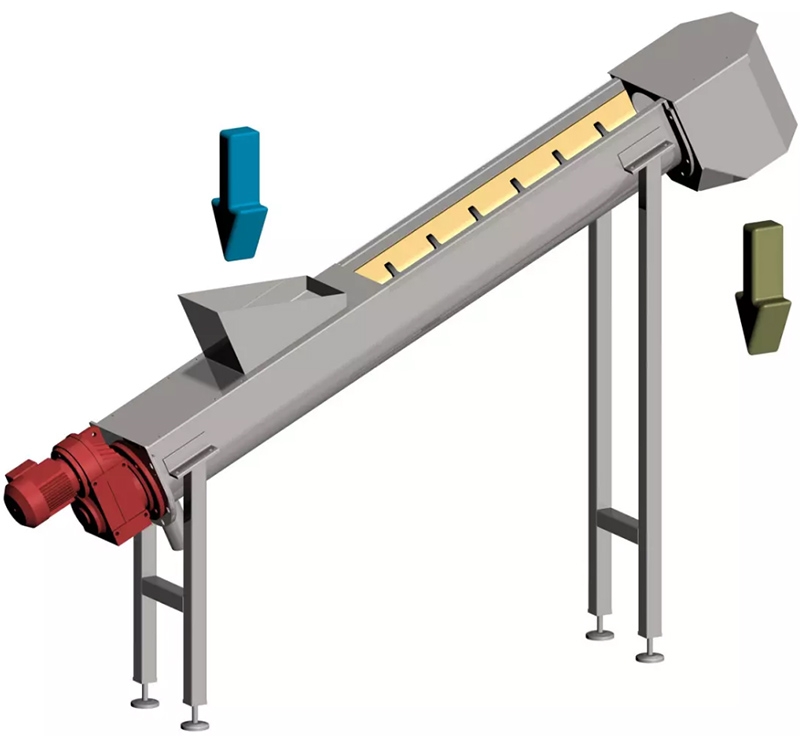

3) LS type shaftless helix conveyor

The shaftless helix conveyor adopts a shaftless design and is specially designed for sticky and winding materials. The shaftless helix conveyor not only makes a breakthrough in materials, but also exceeds 1.5 times the LS type shafted helix in terms of conveying capacity. And the single-pipe conveying length reaches a conveying distance of 60 meters.

Model: WLS200, WLS250, WLS300, WLS350, WLS400, WLS500.

These are just a few examples of helix conveyor models and manufacturers in the market. When selecting a helix conveyor model, it's important to consider factors such as material handling requirements, space constraints, throughput capacity, and customization options to ensure that the chosen conveyor system meets the specific needs of your industry and application.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.