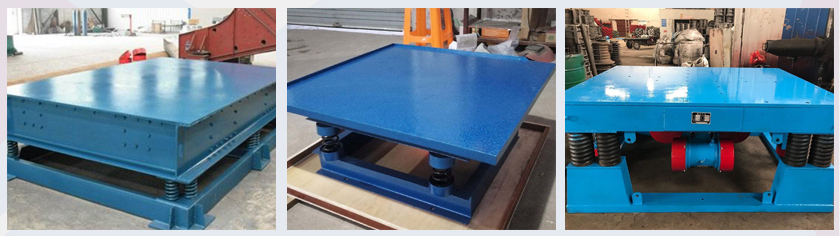

It mainly plays the role of vibration and reduces the air and gaps in the material. It is the vibrator in the production process of cement concrete prefabricated panels.

![]()

![]()

Price:$300.00-$1,500.00/Set

Consult now and enjoy a 10% discount

Power: 7.5kw,

Exciting force: 16-160KN

Vibration frequency: 20-80Hz

Table size: 800*800-4000*3000

Can carry sand box weight: 8T

Application: It is also used to vibrate when the building structure is formed

In it, it is used to vibrate the voids of the filler in the component model and reduce internal air bubbles, thereby increasing the compactness of the molded product and improving product quality

Commitment:

A concrete vibrating table is a machine used in the construction industry to consolidate and settle concrete mixtures. It is typically made of a flat metal surface with a vibrating motor mounted underneath. The motor produces high-frequency vibrations that cause the concrete mixture to settle and compact, removing any air pockets and ensuring that the mixture is evenly distributed.The use of a concrete vibrating table can help to improve the quality of concrete by ensuring that it is properly consolidated. This can help to reduce the likelihood of defects such as honeycombing, cold joints, and delamination, which can compromise the strength and durability of the finished product.

Concrete vibrating tables are commonly used in the production of precast concrete products, such as concrete blocks, pavers, and panels. They can also be used in the construction of concrete slabs, footings, and walls.

The concrete vibrating table is used exclusively in the construction industry to ensure that the concrete mixture is thoroughly set, resulting in a high quality finished product. Apart from the construction industry, concrete vibrating table can be used in various other applications. Here are some examples:

Artistic and decorative concrete: Can be used to create artistic and decorative concrete pieces such as sculptures, fountains and tabletops. These tables help ensure that the concrete is thoroughly set, resulting in a smooth, even surface.

Casting and forming: Can be used to cast and form various objects such as statues, figurines and building components. These tables help remove air pockets from the concrete mix, resulting in a more uniform and consistent end product.

Jewelry making: Can be used in jewelry making to create unique and interesting pieces. By pouring concrete into molds and using a vibrating teble to remove air bubbles, artisans can create custom pieces that are both beautiful and durable.

Testing and research: It can be used for testing and researching the impact of simulated earthquakes and other seismic events on concrete structures. By vibrating concrete samples at high frequencies, researchers can study how materials behave under stress and develop new ways to improve their strength and durability.

A concrete vibrating table works by using high-frequency vibrations to consolidate and settle concrete mixtures. Here's how it works:

1. The concrete mixture is poured onto the surface of the vibrating table, which is typically a flat metal platform.

2. A vibrating motor is mounted underneath the table and produces high-frequency vibrations, typically between 3000 and 6000 vibrations per minute.

3. The vibrations cause the concrete mixture to settle and compact, removing any air pockets and ensuring that the mixture is evenly distributed.

4. The vibrating table may be tilted or rotated to help distribute the concrete mixture evenly and ensure that it reaches all areas of the mold or form.

5. After the concrete has been consolidated on the vibrating table, it is allowed to cure and harden into a solid structure.

Quality improvement

By eliminating air pockets and strengthening the concrete mix, vibrating tables help ensure a high quality finished product and increase strength and durability.

Improve productivity

Can reduce the need to manually consolidate concrete mixes, helping to speed up the production process. This helps to increase productivity and efficiency in the production process.

High power, large table

The maximum power is 2.2kw x (4-5), the excitation force is 120KN, and the load capacity of the sand box is 12T. The maximum load capacity can be designed and manufactured up to 15T.

Versatility

It can be used to produce a variety of concrete products, including precast concrete products, building elements and decorative concrete pieces.

Cost-effective

By ensuring that the concrete mix is thoroughly set, shakers can help reduce the potential for defects and the need for costly repairs. This helps save money and reduces waste during production.

Easy to use

Usually simple to operate and require little training to use effectively. This makes them a convenient choice for small scale producers and DIYers alike.

The dimensions of a concrete vibrating table can vary depending on the specific model and manufacturer. However, here are some typical dimensions for different types of vibrating tables:

Small vibrating table: These tables are typically used for laboratory testing or small-scale production. They may have a surface area of around 2 square feet (0.19 square meters) and a weight capacity of up to 100 pounds (45 kilograms).

Medium vibrating table: These tables are commonly used for production of precast concrete products or for casting and molding larger objects. They may have a surface area of around 4 to 6 square feet (0.37 to 0.56 square meters) and a weight capacity of up to 500 pounds (227 kilograms).

Large vibrating table: These tables are used for industrial-scale production of concrete products or for casting and molding very large objects. They may have a surface area of around 8 to 12 square feet (0.74 to 1.11 square meters) and a weight capacity of several thousand pounds (up to several tonnes).

The concrete vibrating table can be as small as 30*30 cm, and the smaller size is generally 50*50 cm, 80*80 cm, etc. It can be customized according to customer requirements, but it is not easy to customize if it is less than 30 cm up. Commonly used concrete vibrating tables have specifications such as 1*1m, 1.2*1.2m, 1.5*1.5, 2*2m, etc. These dimensions are not fixed and can be customized according to customer requirements. Certain devices can also be attached to the table, designed according to customer vibration requirements to meet your vibration needs.

Choosing the right concrete vibrating table depends on several factors, including the type of concrete product you are making, the size and shape of the molds or forms, and your production volume. Here are some key factors to consider when choosing a concrete vibrating table:

Surface area: Consider the surface area of the vibrating table and whether it is appropriate for your production needs. For example, if you are producing small precast concrete products, a small vibrating table may be sufficient. However, if you are producing larger items or higher volumes, a larger vibrating table may be necessary.

Weight capacity: The weight capacity of the vibrating table is also an important consideration. Make sure that the table can support the weight of your molds or forms, as well as the weight of the concrete mixture.

Vibration frequency and amplitude: The frequency and amplitude of the vibrations produced by the vibrating table can impact the quality of the finished product. Consider the frequency and amplitude settings of the table and whether they are appropriate for the type of concrete product you are making.

Portability: If you need to move the vibrating table frequently, consider a table that is lightweight and easy to transport. Some tables may also have wheels or handles to make them easier to move.

Price: The cost of the vibrating table is also an important consideration. Consider your budget and look for a table that offers a good balance of features and affordability.

Manufacturer and quality: Choose a reputable manufacturer and a high-quality vibrating table to ensure that you get a reliable and durable product that will last for years.

| Model | Table Size(m2) | Power(kw) | Amplitude(mm) | Speed(r/min) | Power(kw) | |

| ZDP-500*500 | 0.25 | 0.25*2 | 2-5 | 150 | 1450 | 0.18*2 |

| ZDP-600*600 | 0.36 | 0.37*2 | 2-5 | 180 | 0.25*2 | |

| ZDP-800*800 | 0.64 | 0.75*2 | 2-5 | 300 | 0.4*2 | |

| ZDP-1000*1000 | 1.0 | 1.1*2 | 2-5 | 450 | 0.75*2 | |

| ZDP-1200*1200 | 1.44 | 1.5*2 | 2-5 | 1200 | 1.1*2 | |

| ZDP-1500*1500 | 2.25 | 1.1*4 | 2-5 | 1800 | 1.5*2 | |

| ZDP-2000*2000 | 4.0 | 1.5*4 | 2-5 | 2500 | 2.2*2 | |

| ZDP-3000*3000 | 9 | 1.5*6 | 2-5 | 3200 | 2.7*2 |

The vibration platform is divided into two-dimensional and three-dimensional vibration platforms. The two-dimensional vibration platform is generally 1 or 2 vibration motors, which are used in industries such as concrete molds, while the three-dimensional vibration platform can choose 2/4/6/8 vibration motors. The vibration strength is stronger, which helps the material to be distributed more evenly, but the cost of the three-dimensional vibration platform is also higher, which will be 290 US dollars-1,015.52 yuan more expensive than the ordinary two-dimensional vibration platform.

The damping springs commonly used in vibration platforms are generally steel springs, rubber springs, and air springs. Choose different configurations according to different applications. Among them, steel springs are the cheapest, but have a small supporting force. They are generally used in small vibration platforms. Rubber springs are moderately priced and commonly used, with good supporting capacity and low noise. The air spring can change the height, and is generally used in occasions where the vibration platform is often raised and lowered, and the cost will be slightly higher.

How the concrete vibrating table is helping the concrete industry:

A small-scale precast concrete product manufacturer

A small business owner who produces precast concrete products such as pavers, blocks, and statues could benefit from using a small vibrating table to consolidate their concrete mixtures. With a small vibrating table, they could ensure that their products are of high quality and free from defects, while also increasing their production capacity.

A large industrial manufacturer

A large-scale manufacturer of concrete products, such as precast panels or large architectural elements, might use a large vibrating table to produce their products. By consolidating their concrete mixtures on a large vibrating table, they could improve the quality and consistency of their products, while also increasing their production volume and efficiency.

A DIY enthusiast

A DIY enthusiast who enjoys making concrete objects, such as garden ornaments, furniture, or decorative items, could benefit from using a medium-sized vibrating table. By using a vibrating table to consolidate their concrete mixtures, they could achieve a professional-quality finish and ensure that their objects are strong and durable. A medium-sized vibrating table could be a good option for someone who wants to produce a variety of different objects, without investing in a large, industrial-grade table.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.