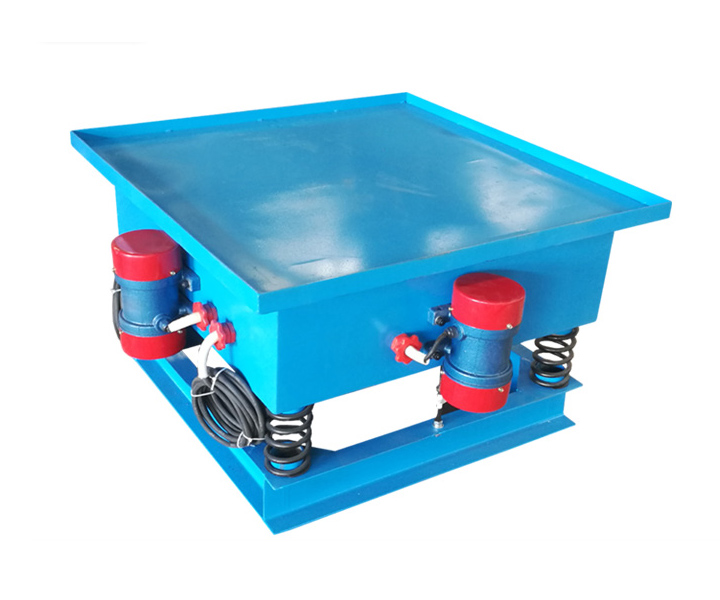

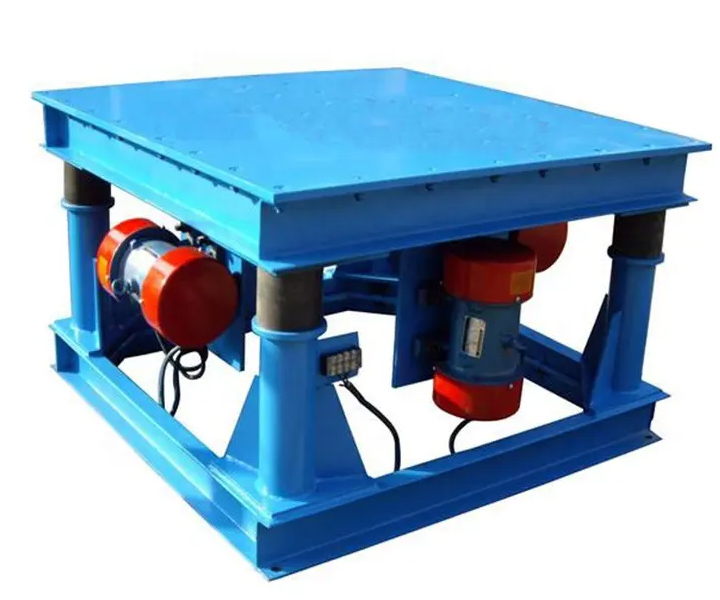

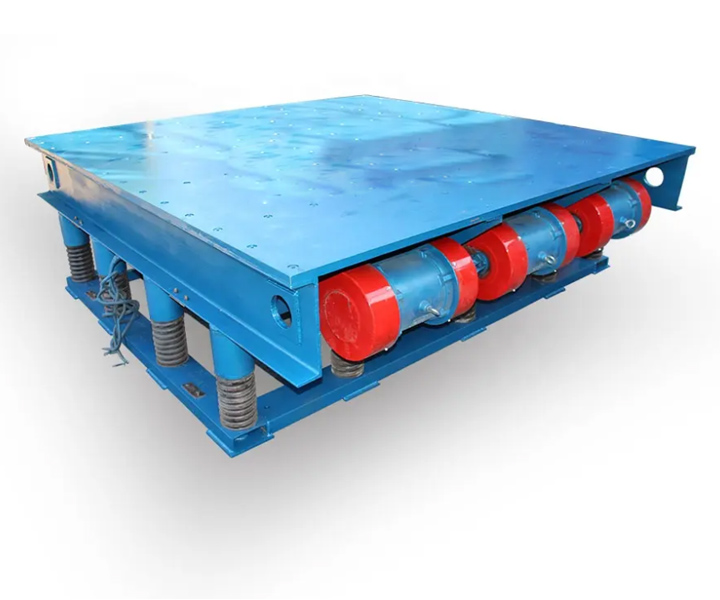

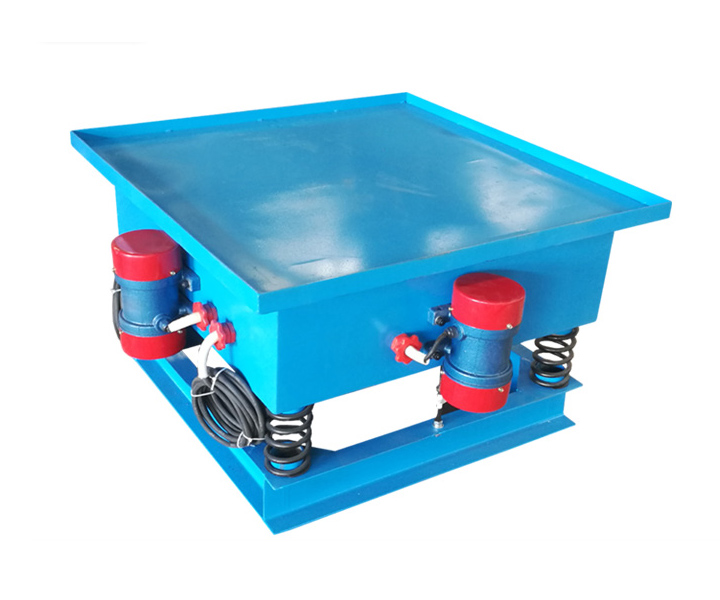

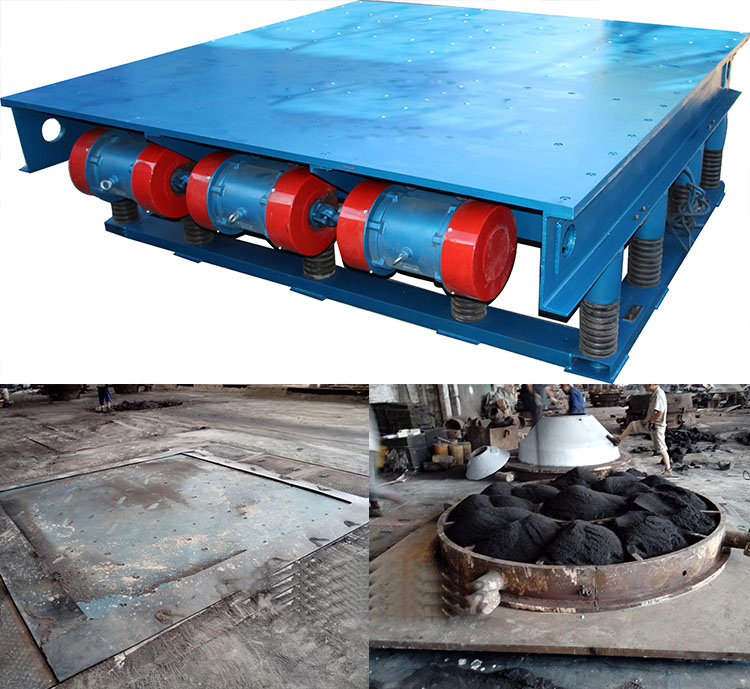

Specialized equipment for settling, compacting and strengthening materials in various industries to improve the quality and consistency of materials and products

![]()

![]()

Price:$600.00-$3,500.00/Set

Consult now and enjoy a 10% discount

Type: 2D vibrating table/3D vibrating table

Power: 7.5kw

Vibration frequency: 20-80Hz

Exciting force: 80KN

Carrying capacity: 8T

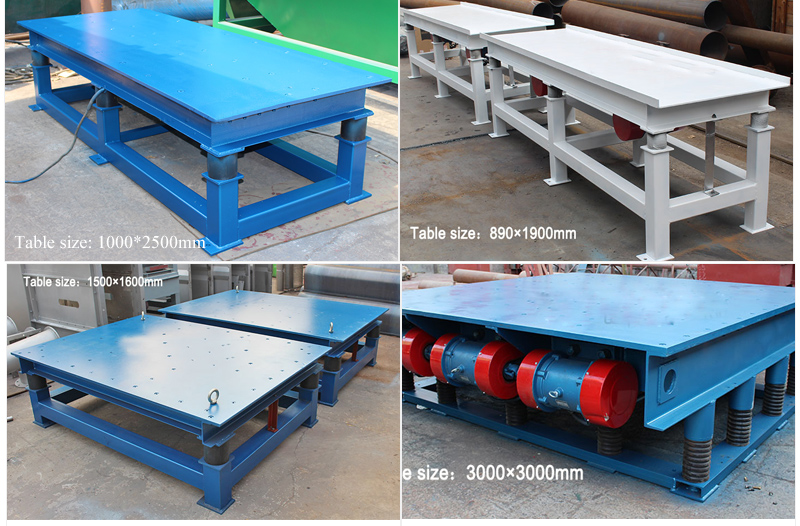

Size: 800-4000*800-3200

Weight: 450-4600kg

Applications: Used in a variety of industries including concrete casting, foundry, food processing, packaging and materials testing.

Commitment:

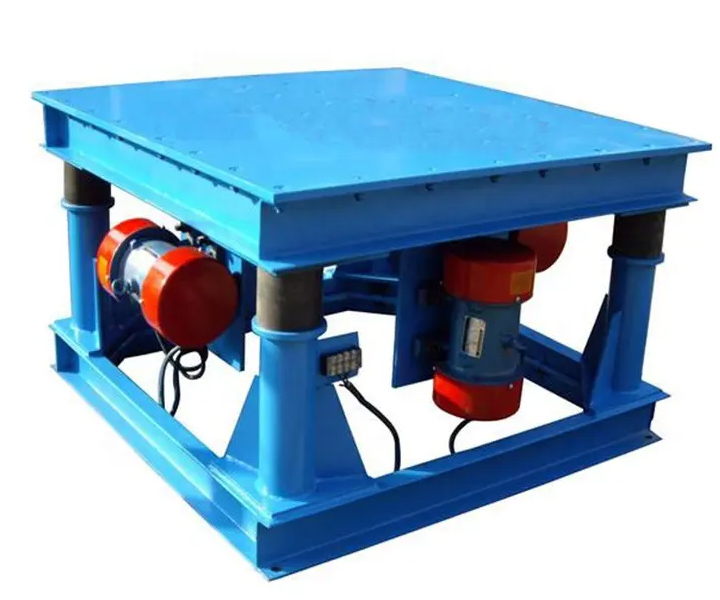

Vibrating table, also known as a vibration table or vibratory table, is a specialized piece of equipment used in various industries to settle, compact, and consolidate materials. The table typically consists of a flat surface that vibrates at a high frequency, usually between 60 and 300 Hz, depending on the specific application.

Vibration tables offer vibrating areas ranging from 800mm to 4000mm wide and 800 to 3200mm long, are used in a variety of industries, including concrete casting, foundry casting, food processing, packaging, and material testing. They are a versatile tool used to improve the quality and consistency of materials and products, and can be customized to suit specific applications and requirements.

There are several types of vibration tables available, each designed for specific applications and requirements. Here are some of the common types of vibration tables:

Two-dimensional Vibration Table

Usually, it only has the ability to vibrate up and down on the table, and the material is under a single force. One or two vibration motors are used. It is used in concrete molds, cement prefabricated parts, air defense doors, ton bag packaging and other industries, which can effectively remove air bubbles in the mold. , to ensure the compactness and quality of the prefabricated parts.

Power is 7.5kw Exciting force: 80KN Load capacity: 15T

Ultrasonic Vibration Table

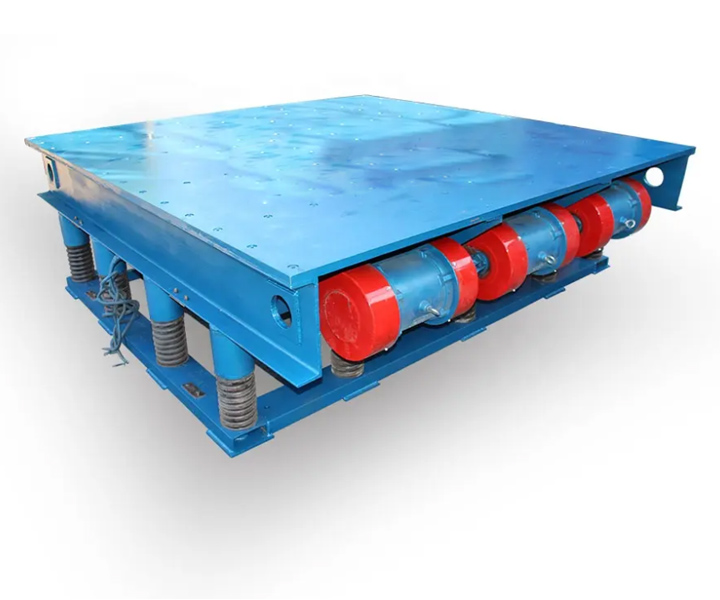

There are 4-8 vibration motors, which have three-dimensional vibration effects of up, down, left, right, front and back. The vibration frequency is adjustable and the production efficiency is high. It has changed the traditional foundry industry. The three-dimensional vibration makes the loose molding sand (dry sand) compact. The solid fixed foam model is mainly used for casting production such as resin sand and lost foam.

Power 2.2kwx (4-5) Excitation force: 120KN Load capacity: 15T

Small Laboratory Vibration Table

Due to its small table top, generally within 500mm, it is obviously different from the common industrial two-dimensional vibrating table. For users, the laboratory vibrating table often needs to form an adjustable frequency conversion vibrating table with a frequency converter, which is mainly used for laboratory testing. , such as earthquake monitoring, building seismic monitoring, etc.

ower 0.25KW* Excitation force: 20KN Load capacity: 3T

The main function of the vibration table is to settle, compact and consolidate materials to improve the quality and consistency of materials and products. The table usually consists of a plane that vibrates at a high frequency, typically between 60 and 300 Hz, depending on the application.

Here are some features of the shaker:

1. Settling and compacting materials: used for settling and compacting materials, such as concrete, sand, food ingredients, powder, etc. The vibration causes the material to settle and removes any air pockets or voids, resulting in a denser and more uniform material.

2. Air bubble removal: In foundry and concrete pouring applications, it is used to remove air bubbles in the material, resulting in a more accurate and consistent casting or concrete product.

3. Reduce settlement during transportation: In packaging applications, it is used to settle and compact products such as powders and granules to reduce settlement during transportation and ensure consistent filling levels in containers.

4. Simulate the impact of vibration: In material testing applications, it is used to simulate the impact of vibration on materials, such as earthquake testing of building components. This helps ensure that materials and products are designed to withstand real-world vibration conditions.

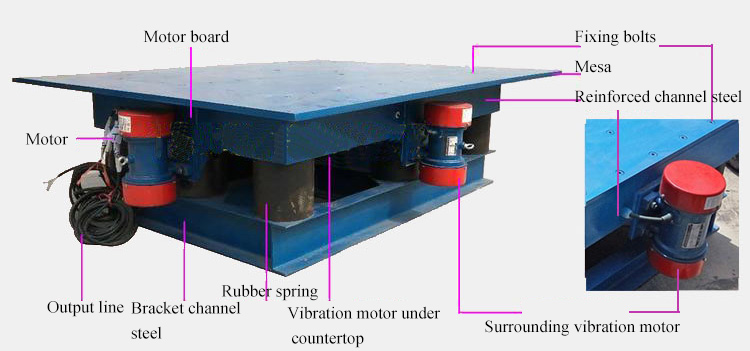

The horizontal vibration motor under the worktable generates enough surging and uniform excitation force and transmits it to the tabletop, thereby driving the cement and other pouring liquids in the mold on the tabletop to generate up and down acceleration under intense vibration, thereby extruding out The air bubbles between the materials reduce the air gap between the pouring liquids, so as to achieve the purpose of improving the quality of pouring molds such as prefabricated parts.

Improve material quality

Helps improve material quality by settling and compacting the material, resulting in a denser, more uniform material.

Improve productivity

The time and labor required to settle and compact material can be reduced, increasing productivity.

Consistent results

Settling and compacting material in an even manner helps ensure consistent results, resulting in a more accurate and consistent finished product.

Reduce waste

Can help reduce waste by more efficiently settling and compacting materials, thereby reducing wasted material due to settling or separation during transport.

Cost-effective

Vibration tables are often a cost-effective solution for settling and compacting materials compared to other methods.

Versatility

It can be customized to specific applications and requirements, and the height of the worktop is adjustable, making it a versatile tool used in a wide variety of industries and applications.

| Model | Table Size (m2) |

Power (kw) |

Amplitude (mm) |

Weight (kg) |

Speed (r/min) |

Power (kw) |

| ZDP-500*500 | 0.25 | 0.25*2 | 2-5 | 150 | 1450 | 0.18*2 |

| ZDP-600*600 | 0.36 | 0.37*2 | 2-5 | 180 | 0.25*2 | |

| ZDP-800*800 | 0.64 | 0.75*2 | 2-5 | 300 | 0.4*2 | |

| ZDP-1000*1000 | 1.0 | 1.1*2 | 2-5 | 450 | 0.75*2 | |

| ZDP-1200*1200 | >1.44 | 1.5*2 | 2-5 | 1200 | 1.1*2 | |

| ZDP-1500*1500 | 2.25 | 1.1*4 | 2-5 | 1800 | 1.5*2 | |

| ZDP-2000*2000 | 4.0 | 1.5*4 | 2-5 | 2500 | 2.2*2 | |

| ZDP-3000*3000 | 9 | 1.5*6 | 2-5 | 3200 | 2.5*2 |

Vibration table is mainly composed of table, vibration motor, shock-absorbing spring and bracket.

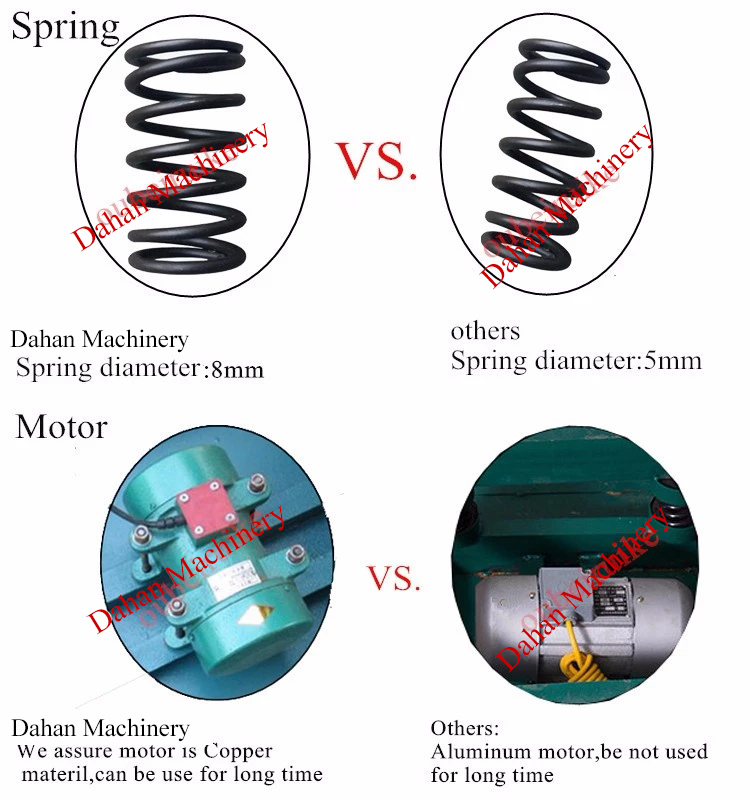

Vibration motor: It consists of several vibration motors and conductive plates. The number of vibration motors can be 2, 4, 6, 8, or 10. The number and model directly affect the relevant parameters of the vibration table.

Shock-absorbing springs: divided into rubber springs, composite springs, and air springs.

Custom vibration tables can be designed to meet specific application requirements. Here are some custom types:

1. Size and shape: The vibration table can be customized to fit specific material sizes and shapes. For example, a square or round table may be better suited for some applications than a rectangular table.

2. Vibration frequency and amplitude: Vibration frequency and amplitude can be tailored to suit specific applications, such as higher frequencies for fine particle separation or lower frequencies for depositing delicate electronic components.

3. Material construction: The materials used to construct the vibration table can be customized for specific applications, such as stainless steel for food processing or aluminum for lightweight applications.

4. Control systems: Control systems can be customized to provide greater precision and control over vibration frequency and amplitude, such as automated systems that adjust vibration based on material density or viscosity.

5. Vibration isolation system: The vibration isolation system can be customized to reduce vibration transmission to other equipment or structures, such as anti-vibration mounts or air suspension systems.

6. Multiple vibration sources: Some vibration tables can be customized to use multiple vibration sources, such as combining electromagnetic and pneumatic drives, to make the vibration more accurate and efficient.

Some of the common applications of vibration tables include:

1. Concrete casting: Vibration tables are used in the concrete casting process to remove air bubbles and settle the concrete mix, resulting in a denser and stronger finished product.

2. Foundry casting: Vibration tables are used in the foundry industry to compact sand molds and remove any air bubbles, resulting in a more accurate and consistent casting.

3. Food processing: Vibration tables are used in the food processing industry to settle and compact ingredients, such as flour and sugar, to improve the accuracy of weighing and reduce settling during transport.

4. Packaging: Vibration tables are used in the packaging industry to settle and compact products, such as powders and granules, to reduce settling during transport and ensure a consistent fill level in containers.

5. Material testing: Vibration tables are used in material testing laboratories to simulate the effects of vibration on materials, such as earthquake testing on building components.

Using a shaker typically involves following these steps:

Place the vibration table stably and connect the power source;

Adjust vibration parameters such as amplitude and frequency;

Place the materials evenly on the vibration table;

Start the shaker and monitor the process;

After the processing is completed, stop the vibration and take out the material;

Clean shaker surfaces and maintain equipment;

Pay attention to safe operation to avoid accidental injury.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.