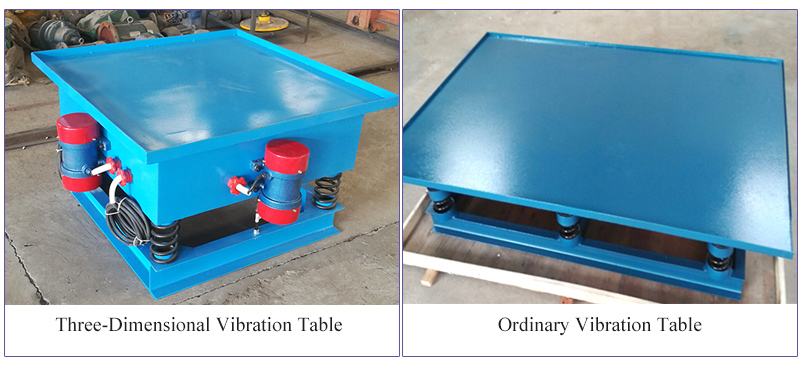

The three-dimensional vibration table can increase the compactness of the molded product and improve the quality of the product by discharging the air bubbles in the material and reducing the internal void. So what is the difference between the three-dimensional vibration table and the ordinary vibration table?

1. The number of motors

The ordinary vibration table adopts 1 or 2 vibration motors, while the three-dimensional vibration table can choose 4, 6, 8, 10 vibration motors, and the vibration force is larger.

2. Vibration track

Ordinary vibrating tables mainly vibrate up and down, while three-dimensional vibrating tables have three-dimensional vibration effects of up, down, left, right, front, and rear, which will make the materials more uniform on the table surface as much as possible during the vibrating process.

3. Application

The bearing weight of the ordinary vibration table can reach 8T, while the bearing weight of the three-dimensional vibration table is 12T.

The above is the difference between the three-dimensional vibration table and the ordinary vibration table. No matter what kind of vibration table you choose, you need to choose the appropriate vibration table according to your own needs, such as space installation requirements, usage, table size, sandbox weight, casting weight, etc. table size, number of motors.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.