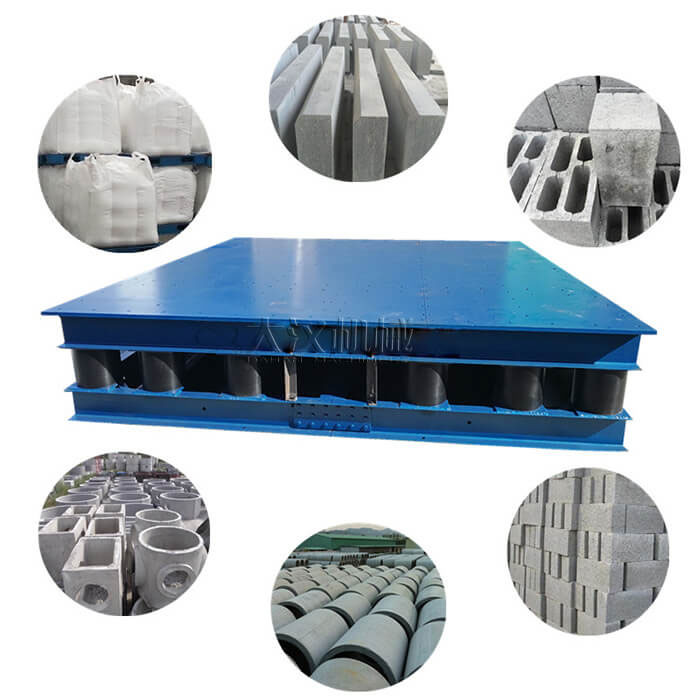

The vibrating table and the vibrating table are also called the three-dimensional vibrating table. During the use of the vibrating platform, the excitation force of the vibrating motor can be adjusted to make the materials on the platform realize the ideal form.

The vibrating table equipment mainly consists of four parts, namely the large bracket, the surface of the platform, the vibrating motor, and the shock absorbing device. Moreover, when performing vibration work, driven by the vibration motor, it will vibrate three-dimensionally-horizontal direction, vertical direction, upward and downward, so it is named three-dimensional vibration platform.

The damping mechanism of the vibrating table is mainly composed of damping springs, which are divided into rubber springs, composite springs, and air springs.

Vibrating table, from the name, we may know that it is mainly used for vibrating materials, so it can also be called a vibrating table. In general, large materials need to be vibrated in the metallurgical industry and building materials industry. In fact, using this kind of vibrating platform can completely replace our manual labor. Its work efficiency is higher, its quality is better, and it is relatively easy to operate. Its structure is simple and its footprint is small. The air and small gaps retained in the material are reduced, so more and more industrial producers will choose to use a vibrating platform when vibrating materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.