Designed specifically for clay transportation to eliminate manual handling and reduce labor costs

![]()

![]()

Price::$800.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Belt Width: 500-1800mm

Height of Sidewall: 80-500mm

Belt Speed: 0.8-4.0m/s

Angle of Inclination: 30-90 degrees

Capacity: 84-5036m³/h

Application:Conveyor systems specifically designed for transporting clay or similar materials in various industries such as mining, ceramics, construction and agriculture.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

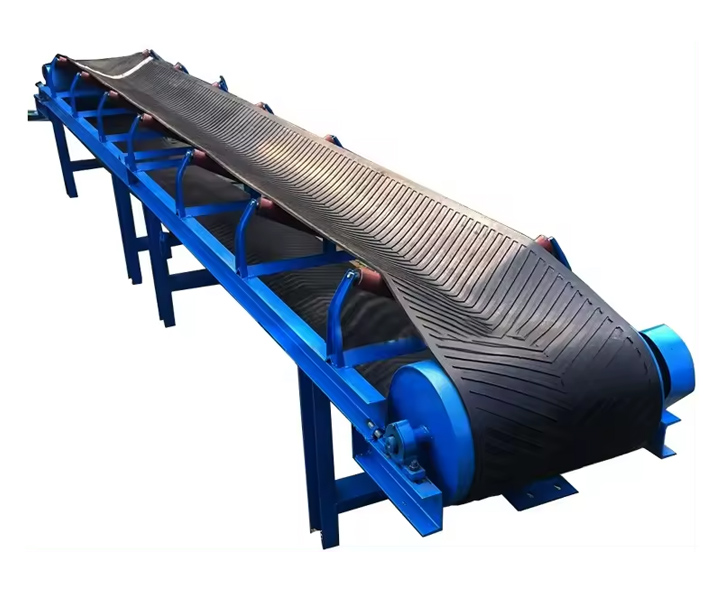

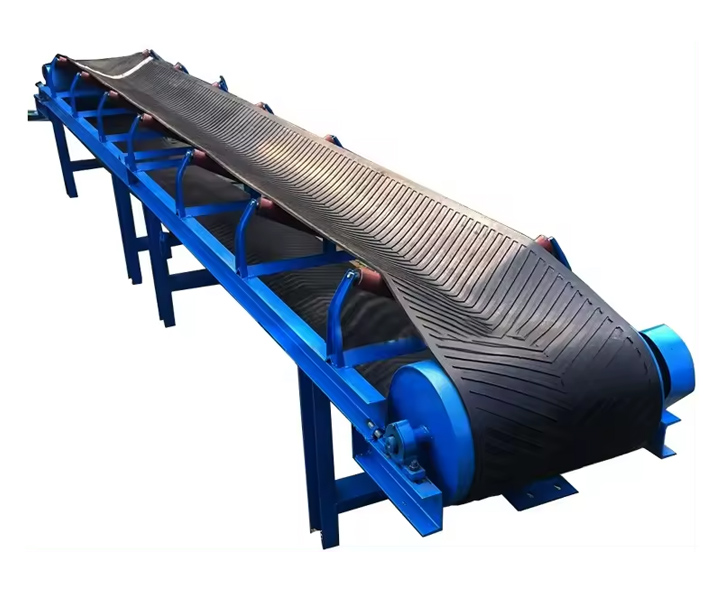

Clay belt conveyor is a type of conveyor system specifically designed for handling clay or clay-like materials. Clay, being a cohesive and often sticky material, requires specialized conveyors that can effectively transport it without issues such as material buildup, blockages, or excessive wear on the conveyor components.

Clay belt conveyors are designed to handle the challenges associated with clay materials, such as their cohesive nature and potential for sticking to surfaces. The conveyor belt's rough surface texture and proper belt tensioning help prevent material adhesion and ensure continuous and reliable transport. Additionally, some clay belt conveyors may have adjustable speed and incline/decline capabilities to accommodate various clay handling requirements.

Ordinary clay belt conveyor: It is suitable for general clay transportation needs and has relatively basic transportation functions.

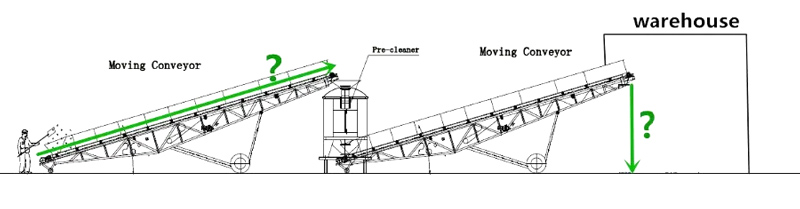

Inclined clay belt conveyor: Used in situations where inclined conveying is required. The conveying angle can be adjusted as needed and is suitable for special process requirements.

Folding clay belt conveyor: It can be folded and unfolded as needed, suitable for occasions with limited space or where flexible layout is required.

Flat clay belt conveyor: The flat belt conveyor uses driving rollers and support rollers for transmission, and is used to transport various bulk materials or finished materials horizontally or inclined.

Here are some other applications of clay belt conveyors:

Clay Mining and Excavation: Transporting clay from mining sites to processing plants or storage facilities. They enable efficient, continuous movement of clay to optimize the mining process.

Clay Processing and Manufacturing: Transporting clay from storage areas to various processing stages such as grinding, crushing, mixing, shaping and drying. The conveying system ensures a smooth flow of clay which contributes to efficient production.

Pottery and ceramic glazing: Used in the glazing process. They transport pottery such as pottery or pottery through a glazing station, where a glaze is applied. A conveyor system ensures precise movement and positioning of the pottery, facilitating the glazing process.

Clay Waste Management: Transport and disposal of clay waste materials. These materials can include clay sludge, clay left over from the production process, or clay-based waste.

Clay product packaging: Transporting packaged products from the production line to the packaging area ensures a smooth and efficient packaging process.

Efficiency

Using a belt conveyor for clay transportation improves efficiency by eliminating the need for manual handling and reducing labor costs.

Consistency

The conveyor system helps maintain the consistency of clay transport by ensuring a continuous and uniform flow of material.

Reduced Spillage

Belt conveyors are designed to minimize spillage of clay during transportation, reducing material wastage and improving cleanliness in the work environment.

Enhanced Safety

Manual handling of clay can be physically demanding and prone to injuries. Clay belt conveyors reduce the risk of accidents and injuries associated with manual lifting, carrying, and transportation of heavy loads.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | >15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

A clay belt conveyor typically consists of the following components:

Belt: The conveyor belt is the primary component responsible for carrying the clay material. It is typically made of a durable and flexible material, such as rubber, with a rough surface texture to prevent material slippage.

Belt Support Structure: This structure provides support and stability for the conveyor belt. It includes rollers or idlers that help guide and support the belt along its path.

Drive System: The drive system powers the conveyor belt, usually through an electric motor, gearbox, and pulleys. It controls the speed and movement of the belt, allowing the clay to be transported smoothly.

Clay-specific Features: Clay belt conveyors may have additional features to accommodate the unique characteristics of clay. For example, they may include scraper blades or cleaning mechanisms to prevent material buildup on the belt surface.

Building Materials Manufacturer

A manufacturer of building materials uses belt conveyors to transport clay from storage areas to mixing plants. This automated conveying system improves the efficiency of clay transportation and ensures a stable supply to meet the needs of the production line.

Clay Suppliers

Clay suppliers use belt conveyors to transport clay from their production sites to their customers' factories or processing facilities. The conveyor ensures a continuous supply of clay, improves logistics efficiency, and provides customers with timely supply of raw materials.

Brick Production Factory

A brick and tile production plant uses belt conveyors to transport clay from storage areas to forming machines. By using conveyors, they achieved a continuous supply of clay, reducing manual handling and improving production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.