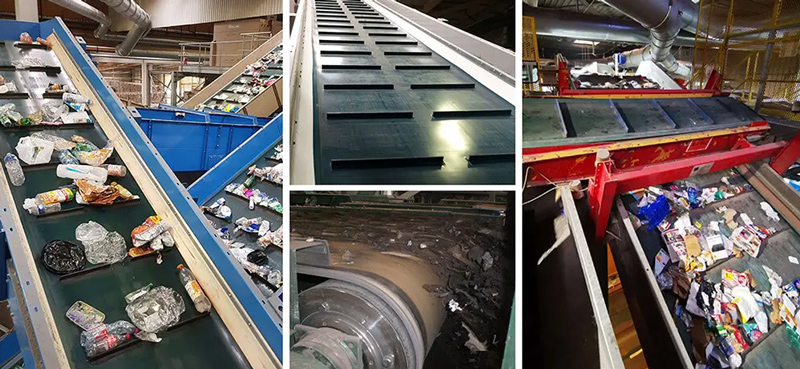

Specially used to transport municipal solid waste, construction waste, recyclables and industrial waste.

![]()

![]()

Price::$680.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Conveying angle: 0-90°

Belt width: 300-1500mm

Belt Type: Skirt

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Belt material: PVC, PU, rubber

Frame material: SUS304 stainless steel/carbon steel/aluminum

Weight: 300 kg

Application: Used for transporting waste materials in various industries such as recycling facilities, waste management plants, construction sites, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Waste belt conveyor is a type of conveyor system used for transporting waste materials or garbage from one location to another. It is commonly used in waste management facilities, recycling plants, and other industrial settings where there is a need to efficiently handle and dispose of waste.

The waste belt conveyor consists of a continuous belt that moves along a series of pulleys or rollers. The belt is typically made of durable material, such as rubber or PVC, to withstand the harsh conditions and abrasive nature of waste materials. The conveyor belt is powered by a motor that drives the pulleys, causing the belt to move and transport the waste materials along its length.

1. Recycling facilities: Waste belt conveyors are commonly used in recycling plants to transport and sort recyclable materials such as paper, plastic, glass and metal.

2. Waste Management Facilities: These conveyors play a vital role in waste management facilities that handle municipal solid waste, construction waste, and other types of waste.

3. Construction sites: Construction sites utilize waste belt conveyors to transport construction and demolition waste for recycling or disposal.

4. Industrial Environment: In industrial facilities, waste belt conveyors help in the safe and efficient management and disposal of various types of industrial waste.

Improved Efficiency

Waste belt conveyors streamline waste handling processes, reducing manual labor and increasing operational efficiency.

Environmental Impact

Proper waste management facilitated by belt conveyors contributes to environmental sustainability through recycling and proper disposal practices.

Versatility

The waste belt conveyor can handle a wide range of waste materials, including large items, loose waste, and compacted waste. It is designed to accommodate various types of waste streams and can be customized to suit specific waste management needs.

Continuous Operation

The conveyor system ensures a smooth and continuous flow of waste materials, minimizing downtime and maximizing productivity. It helps streamline waste handling processes and improves overall operational efficiency.

Safety

By automating the transportation of waste materials, these conveyors help improve workplace safety by minimizing the risk of injuries associated with manual handling.

Durability

Waste materials can be heavy, bulky, and abrasive. The waste belt conveyor is built with robust construction and materials that can withstand the harsh conditions and handling of waste materials.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

Waste belt conveyors can be effectively integrated with sorting systems or shredders in waste management and recycling operations. Here are two common integration methods:

1.Sorting Systems Integration:

Automated sorting systems can be positioned along the waste belt conveyor line. These systems use various technologies such as optical sensors, magnetic separators, or air blowers to identify and separate different types of waste materials.

As the waste materials are transported on the belt conveyor, they pass through the sorting stations where the sorting systems identify and divert specific materials to designated collection points or processing equipment.

The sorting systems can be programmed to recognize and sort materials such as paper, plastic, metal, glass, or other recyclables, allowing for efficient separation and recycling.

2.Shredder Integration:

Shredders are commonly used to break down waste materials into smaller pieces for further processing or disposal.

Waste belt conveyors can be integrated with shredders by positioning the shredder at a designated point along the conveyor line, such as an offloading station or a sorting station.

The waste materials transported on the belt conveyor are directed into the shredder for size reduction. The shredded waste is then discharged onto another section of the conveyor or into a separate collection bin for further processing or disposal.

The integration of shredders with waste belt conveyors enhances the efficiency of waste processing, particularly in applications where large volumes of waste need to be reduced in size before further handling or disposal.

| Client | Convey products | Application occasions | Use |

| America**Waste Management Company | garbage of urban life | garbage treatment plant | Transport waste to sorting station |

| South Africa ** construction company | construction waste | construction site | Transporting waste to treatment facilities |

| Indonesia **manufacturing plant | industrial waste | manufacturing production line | Transport waste to recycling bins |

| Chile’s ** Electronics Recycling Company | electronic waste | Electronic waste treatment plant | Conveying e-waste for sorting and recycling |

| Singapore** Pulp Factory | pulp waste | Pulp production line | Conveying scrap to recycled paper manufacturing equipment |

Xinxiang Dahan waste belt conveyor manufacturer is a trusted leading manufacturer in the waste management and recycling industry, focusing on designing and producing efficient, durable conveyor systems to help customers improve production efficiency, reduce operating costs, and is committed to environmentally friendly and sustainable development. Known for innovative technology, high-quality materials and superior performance, its products provide customers with customized solutions for a variety of waste disposal needs.

Bandwidth: Bandwidths include 500mm, 600mm, 800mm, etc. If you need different bandwidths, please inform us in advance.

Length: Waste belt conveyor lengths are 6 meters, 8 meters, 10 meters, 12 meters, 15 meters, and 20 meters (20 meters requires special notification, and the fuselage structure is different).

Need to know about special circumstances: If you are transporting highly polishable materials, please inform us in advance. If there are special requirements for specific length, bandwidth and output, special design and production can be done.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.