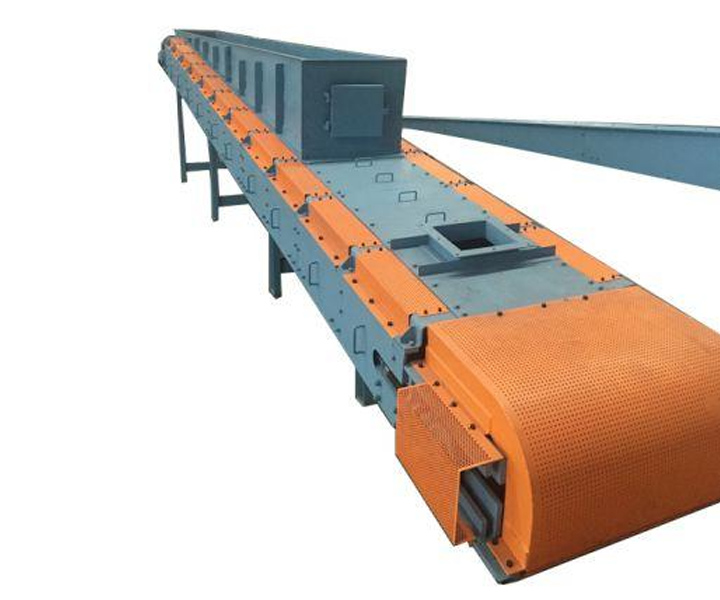

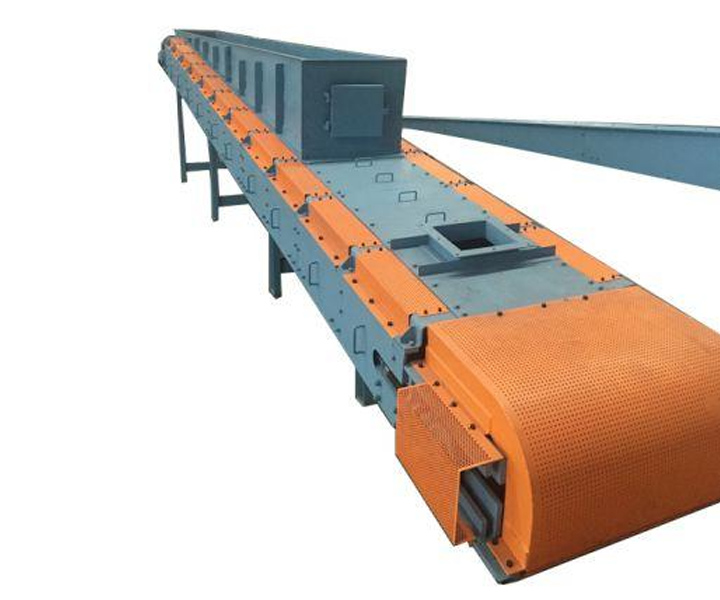

It is a conveying system specially used to process and transport sludge.

![]()

![]()

Price:$680.00 - $22,800.00/Set

Consult now and enjoy a 10% discount

Belt width: 300-1500mm

Conveying angle: 0-30°

Belt Type: Skirt

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Frame material: SUS304 stainless steel/carbon steel/aluminum

Weight: 300 kg

Application: Commonly used in wastewater treatment plants, industrial facilities and other applications where sludge needs to be transported

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Belt conveyor for sludge is a type of conveyor system specifically designed for handling sludge, which refers to the semi-solid or solid residue generated from various industrial processes, wastewater treatment plants, or other applications. It is commonly used in sewage treatment plants, sludge treatment facilities, sewage treatment plants and other industrial sites. The equipment consists of a continuous belt driven along a series of rollers to transport sludge from one location to another.

The design of belt conveyor for sludge can be customized according to specific needs to meet the conveying requirements of different places. Belt conveyor for sludge can be used in conjunction with other equipment to realize an automated sludge treatment system. It can be connected with sludge drying equipment, thickeners, centrifuges and other equipment to achieve continuous processing and transportation of sludge.

Curve belt conveyor for sludge: It is a specially designed conveying equipment suitable for occasions where curved conveying is required in a limited space. It can transport sludge along a curved path and is suitable for connections between treatment equipment or when plant layout is restricted.

Inclined belt conveyorfor sludge: Designed to transport sludge between different heights. Through the inclined design, it can help the sludge be transported smoothly from one location to another, which is suitable for scenarios where height differences need to be crossed.

Folding belt conveyor for sludge: usually used in situations where long-distance transportation is required in a limited space. Its design allows the belt to fold during conveying, making it suitable for connections between factories or processing equipment where space is limited.

Belt conveyors for sludge can be used to transport many types of sludge, including but not limited to the following:

The conveyor needs to be appropriately adjusted and configured according to the characteristics and treatment requirements of different types of sludge to ensure effective transportation and treatment. In addition, due to the viscous nature of sludge, measures may need to be taken to prevent clogging and leakage, such as selecting appropriate conveyor belt materials and installing sealing devices.

Dewatered sludge: Belt conveyors can be used to transport dewatered sludge from dewatering equipment to other processing units, such as sludge drying equipment or storage facilities.

Biological sludge: Belt conveyors can be used to transport biological sludge from the treatment unit to subsequent treatment steps, such as anaerobic digesters or sludge thickeners.

Coagulated sedimentation sludge: Belt conveyors can be used to transport coagulated sedimentation sludge from sedimentation tanks or sedimentation tanks to subsequent treatment equipment, such as sludge thickeners or drying equipment.

Agricultural sludge: Belt conveyors can be used to transport agricultural sludge from farms or farmland to compost piles or other treatment facilities, such as biogasification equipment.

Industrial sludge: Belt conveyors can be used to transport industrial sludge from production equipment to treatment facilities, such as dryers, incinerators, or recovery units.

Efficient and fast

It can run continuously and transport large amounts of sludge from one location to another, saving labor and time costs.

Automated processing

It can be connected with sludge drying equipment, concentrators, centrifuges and other equipment to achieve continuous processing and transmission of sludge.

Reduce manual intervention

Using belt conveyors to transport sludge can reduce the need for manual intervention and manual handling, improving safety and work efficiency.

Adapt to different environments

It can be designed for horizontal conveying, inclined conveying or vertical lifting to adapt to different space layouts and process requirements.

Reduce sludge treatment costs

It can reduce labor and transportation costs, improve processing efficiency, and reduce loss and waste during processing.

Improve processing effect

The belt conveyor can transport sludge evenly and stably, ensuring that the sludge maintains consistent quality and status throughout the entire transportation process.

When comparing belt conveyors and screw conveyors for sludge handling, there are several factors to consider:

Handling Capacity: Belt conveyors are generally more suitable for handling larger volumes of sludge. They have a higher capacity and can handle heavy loads. Screw conveyors, on the other hand, are better suited for lower capacity applications.

Efficiency: Belt conveyors are known for their high efficiency in moving bulk materials, including sludge. They can transport sludge at a faster rate and with less power consumption compared to screw conveyors.

Space Requirements: Screw conveyors are often more compact and require less space compared to belt conveyors. They can be easily installed in tight spaces or areas with height restrictions.

Cost: Screw conveyors are generally more cost-effective compared to belt conveyors, especially for smaller capacity applications. They have a simpler design, require less power, and are generally more economical to purchase and maintain.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

Conveyor Belt Design: The conveyor belt used for sludge handling is designed to withstand the heavy load and abrasion caused by the viscous nature of sludge. It is typically made of durable materials such as rubber or synthetic compounds with a high resistance to wear and tear.

Sludge Containment: Belt conveyors for sludge often incorporate features to prevent spillage and containment of the material being transported. This can include side skirts, drip pans, or covers to minimize the release of sludge and maintain a clean working environment.

Corrosion Resistance: Sludge often contains corrosive elements, so the conveyor system should be constructed from materials that can withstand exposure to these substances.

Sealing: Proper sealing is essential to prevent leakage and odor emissions during the transportation of sludge.

Cleaning System: Belt conveyors for sludge may incorporate cleaning systems such as scrapers or brushes to prevent material buildup and ensure smooth operation.

| Client's name | Industry | Application description |

| Sewage treatment plant | Public utilities | Used to transport coagulated sedimentation sludge from the sedimentation tank to the drying equipment. |

| Industrial plants | manufacturing | Metal processing waste sludge is transported from production equipment to incinerators for processing. |

| Livestock and poultry farms | agriculture | It is used to transport the sludge after treatment of livestock and poultry breeding waste to the compost pile for resource utilization. |

| Food processing plants | Food Industry | It is used to transport the sludge after food processing wastewater treatment to the sludge thickener for further treatment. |

| textile factory | Textile industry | The sludge after textile wastewater treatment is transported from the treatment equipment to the dryer for solid waste treatment. |

| Municipal Environmental Corporation | city management | It is used to transport the activated sludge produced by the municipal sewage treatment plant to the anaerobic digester for organic matter degradation treatment. |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.