Clay belt conveyor is a type of conveyor system specifically designed for transporting clay or similar materials in various industries, such as mining, ceramics, construction, and agriculture. This article will give you a detailed introduction to how to choose a clay belt conveyor.

Here are some key considerations to keep in mind when choosing a clay belt conveyor:

1. Material Characteristics:

Clay Type: Consider the specific type of clay you are handling, including its moisture content, particle size, abrasiveness, and any other unique properties that may impact the conveyor system.

Flowability: Ensure the conveyor is designed to handle the flow characteristics of the clay material without causing blockages or spillage.

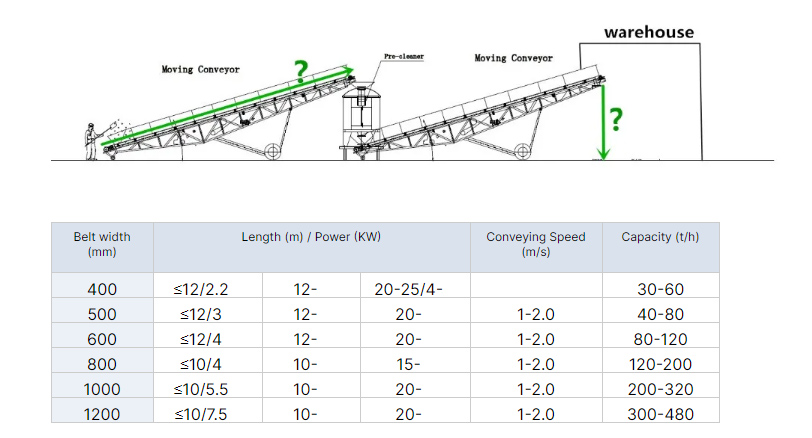

2. Capacity and Throughput:

Material Volume: Determine the required capacity of the conveyor system based on the volume of clay that needs to be transported within a given time frame.

Throughput Requirements: Select a conveyor with the appropriate speed and load capacity to meet your production demands.

3. Conveyor Design:

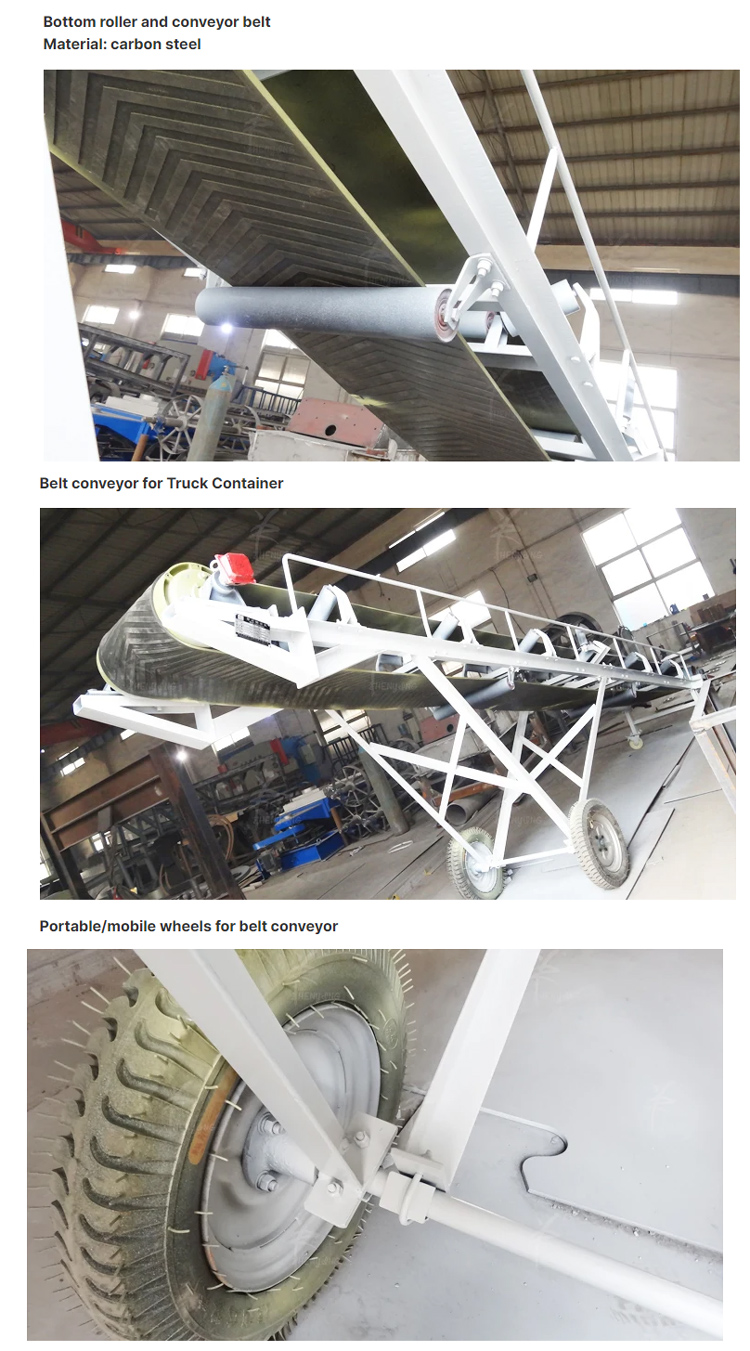

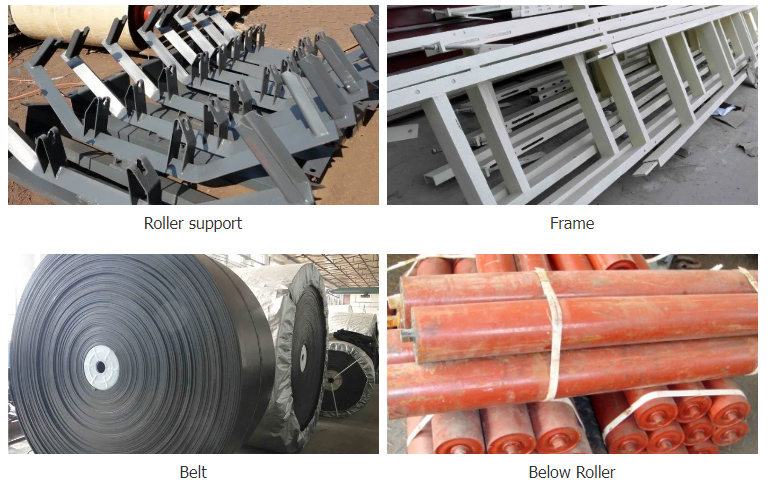

Belt Type: Choose a conveyor belt that is specifically designed to handle clay material, considering factors such as belt material, thickness, and surface texture.

Frame Construction: Opt for a conveyor with a sturdy frame construction that can withstand the abrasive nature of clay and provide long-term durability.

4. Environmental Considerations:

Operating Conditions: Consider the operating environment where the conveyor will be used, including temperature, humidity, and exposure to dust or other contaminants.

Indoor vs. Outdoor Use: Determine whether the conveyor will be used indoors or outdoors and select a system that is suitable for the specific environment.

5. Maintenance and Cleaning:

Ease of Maintenance: Choose a conveyor system that is easy to maintain, with accessible components for inspection, cleaning, and routine maintenance.

Cleaning Requirements: Consider the cleaning needs of the conveyor to prevent material buildup and ensure optimal performance.

6. Safety Features:

Safety Guards: Ensure the conveyor system is equipped with appropriate safety features such as guards, emergency stops, and safety sensors to protect operators and prevent accidents.

Compliance: Verify that the conveyor system meets relevant safety standards and regulations for your industry.

7. Budget and Cost Considerations:

Initial Investment: Consider the initial cost of the conveyor system, including installation and setup expenses.

Operating Costs: Evaluate the long-term operating costs, including energy consumption, maintenance, and potential repairs.

By carefully considering these factors and conducting thorough research, you can choose a clay belt conveyor that is well-suited to your specific material handling requirements, ensuring efficient and reliable transportation of clay in your industrial or manufacturing operations.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.