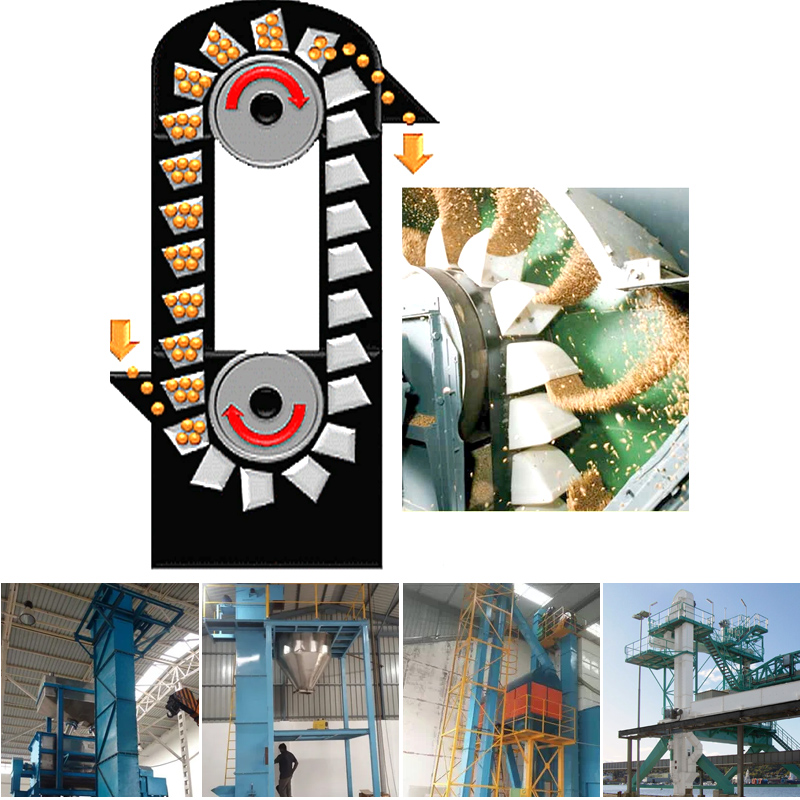

Vertical transportation of various feeds in fields such as feed processing plants, feed warehouses, breeding farms and grain storage

![]()

![]()

Price::$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Feeding size: 25-70mm

Capacity: 5.4-800m³/h

Lifting height: 40m

Lifting speed: 1.4-2m/s

Application:Commonly used in feed mills, grain storage facilities and other applications requiring vertical movement of bulk materials. They help streamline material handling processes, increase productivity and optimize space utilization.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Feed bucket elevator is a machine that is used to vertically convey bulk materials such as animal feed, grain, and pellets. It is a type of conveyor that uses a continuous belt or chain with attached buckets to scoop up material at the bottom and carry it to the top, where it is discharged.

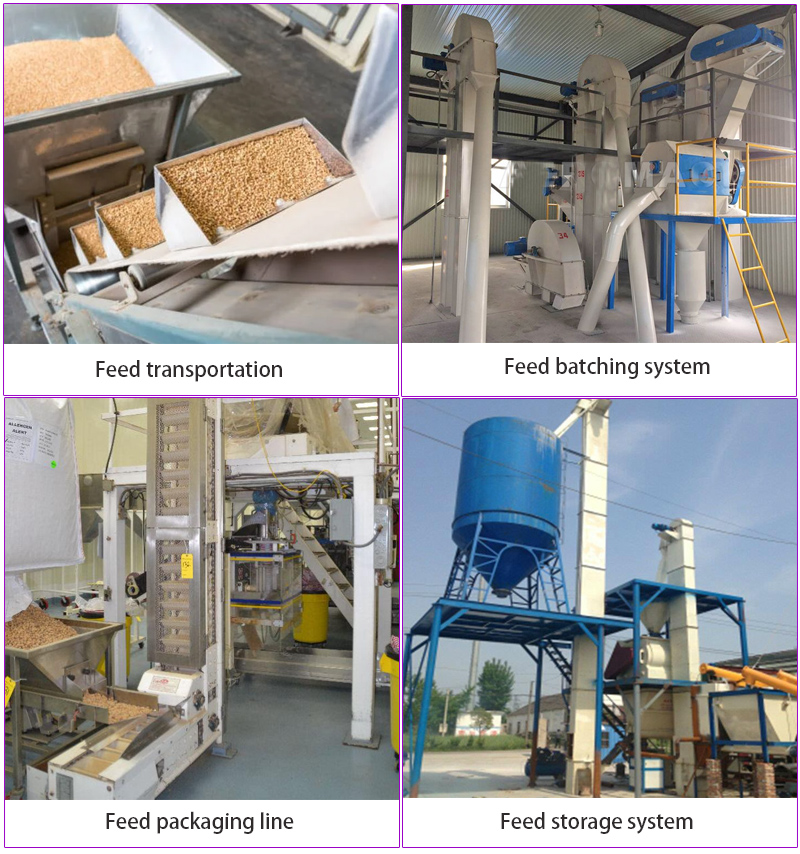

Feed bucket elevator plays an important role in the feed industry. It can efficiently transport feed vertically and is used in multiple links such as feed transportation, batching systems, packaging lines and storage systems. By providing accurate ingredients, processing and packaging, it improves production efficiency and ensures feed quality and safe storage.

Feed bucket elevators have a wide range of uses in the feed industry, including the following:

1. Feed transportation: Feed bucket elevators are used to vertically lift feed from one location to another, such as from the ground to a storage bin or into processing equipment such as mixers and crushers.

3. Feed batching system: In the feed batching system, the feed bucket elevator is used to lift different feed ingredients or additives to the batcher or mixer to achieve accurate batching and mixing process.

3. Feed packaging line: In the feed packaging line, the feed bucket elevator is used to vertically lift the finished feed from the outlet of the production line to the packaging machine or storage container for packaging, encapsulation and storage.

4. Feed storage system: Feed bucket elevator can also be used in feed storage systems to lift feed from the ground or other locations to storage bins or hoppers.

Feed bucket elevator can lift various types of feed, including but not limited to the following:

1. Pellet feed: such as feed pellets, grain pellets, soybean meal, etc.

2. Powdered feed: such as feed powder, feed additives, feed formula, etc.

3. Chopped feed: such as silage, hay, feed lumps, etc.

4. Feed mixture: including mixtures of various feed ingredients, such as complete feed, premix, etc.

Feed bucket elevator is a type of vertical conveyor system specifically designed for handling and transporting feed and similar bulk materials in the agricultural and livestock industry. It is commonly used in feed mills, grain storage facilities, and animal production operations.

| Application occasions | Convey products | use | Lift height |

| feed processing plant | feed pellets | storage and distribution | 10 m |

| livestock farm | silage and hay | Feeding materials to storage silo | 6 meters |

| grain storage bin | grain pellets | Unload to storage bin | 15 meters |

| Breeding pigeon breeding farm | pigeon feed | Delivered to feeder | 4 meters |

| Feed formula truck | feed formula mixture | Transfer to production line | 8 meters |

Efficient vertical transport

Feed bucket elevators are designed for efficient vertical lifting and transportation of feed materials. They can handle large volumes of feed and provide a continuous, reliable flow of material, reducing physical labor and increasing productivity.

Space-saving design

Bucket elevators are compact in design and can be transported vertically, making them ideal for areas with limited floor space. They make efficient use of vertical space, allowing for efficient material handling in tight production environments.

Handle feed gently

Feed bucket elevators are designed to handle feed materials gently, minimizing product damage and maintaining feed integrity. The bucket scoops up feed without causing excessive breakage or degradation, ensuring the quality of the final product.

Versatility

Feed bucket elevators can handle various types of feed ingredients, including grains, pellets and other feed ingredients. They can be adapted to different feed sizes and densities, making them suitable for a variety of feed production applications.

Customizable options

Feed bucket elevators can be customized to meet specific requirements. They are available in different sizes, capacities and configurations, allowing the flexibility to match the lift to production needs and installation constraints.

Dust and Spill Control

Bucket elevators are typically enclosed in a casing or casing, which helps control dust and prevent spills during material handling. This contributes to a cleaner, safer work environment.

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

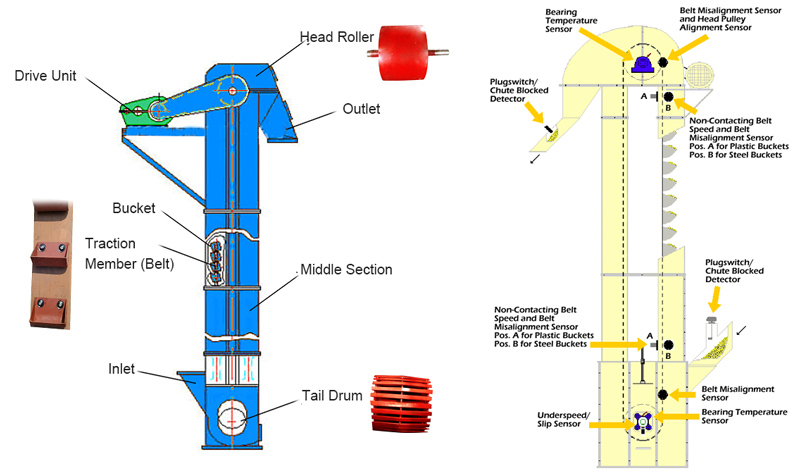

The operation of a feed bucket elevator is similar to that of a grain bucket elevator. Here are the key components and functions:

Buckets: The buckets in a feed bucket elevator are typically made of durable materials, such as plastic or metal, and are attached to a belt or chain. These buckets are designed to securely hold and transport the feed materials during the lifting and conveying process.

Lifting mechanism: The buckets are mounted on a continuous loop belt or chain that moves vertically or at an incline. The belt or chain is driven by a motor, providing the necessary power for lifting the feed materials to higher levels.

Loading and discharging: Feed materials are loaded into the buckets at the bottom of the elevator. As the buckets move along the vertical or inclined path, they carry the feed materials upwards. When the buckets reach the desired level, they tip over, allowing the feed to be discharged into a storage bin, mixing equipment, or other processing machinery.

How can feed bucket elevators help in preventing feed damage during transportation?

The Feed Bucket Elevator is designed to minimize damage to the feed during transport, ensuring that the feed retains its quality and nutritional value. Here are some ways a feed bucket elevator can help prevent feed damage:

1. Hopper design: The hopper used in the feed bucket elevator is carefully designed to handle the feed without causing excessive damage. They are usually made of durable materials, such as plastic or metal, and are shaped to hold feed securely while minimizing spillage, breakage or degradation during lifting and conveying.

2. Gentle handling: Feed bucket elevator is designed for gentle handling of feed materials. The bucket moves at a controlled speed, ensuring feed is lifted and transported smoothly without excessive shock or turbulence. This prevents feed breakage or degradation that can occur in more aggressive treatments.

3. Proper Bucket Spacing: Spacing between buckets on a lift belt or chain is critical to prevent feed damage. It should be optimized to ensure that the feed is adequately contained within the bucket without over compacting. Proper bucket spacing can lift adequate amounts of feed while minimizing the risk of feed being crushed or overstressed.

4. Material selection: The material selection used in the structure of the feed bucket elevator is compatible with the feed processing. They are generally resistant to wear and corrosion to ensure long-term durability and minimize the risk of contamination. Careful material selection helps prevent feed damage and maintain feed quality during transport.

The feed bucket elevator can be used as a separate device or can be combined with other equipment to form a complete feed production line. Combining the feed bucket elevator with other equipment can realize an automated and continuous feed production process, improving production efficiency and product quality.

Here are some common pieces of equipment used in conjunction with feed bucket elevators:

1. Crusher: used to crush feed raw materials to make them more suitable for subsequent processing and mixing processes.

2. Mixer: used to mix different feed ingredients to achieve specific feed formulas and nutritional requirements.

3. Pellet Mill: used to pellet the mixed feed raw materials to produce pelletized feed.

4. Cooler: used to reduce the temperature of the feed after pelleting for storage and packaging.

5. Packaging Machine: used to package feed into appropriate packaging forms, such as bags, bulk, etc.

The following are some application examples of feed bucket elevators:

| Applications | Conveying materials | Lift amount | Lift height |

| Feed processing plant/td> | Feed raw materials, additives, mixed feed | 10-200 tons/hour | 2-30 meters |

| Feed warehouse | feed, grain | 10-100 tons/hour | 5-20 meters |

| Breeding farm | feed | 1-10 tons/hour | 2-6 meters |

| Grain storage | Grain, feed | 10-500 tons/hour | 10-50 meters |

| Powder material production | Powdered feed, powder additives | 1-20 tons/hour | 2-10 meters |

| Seed treatment plant | Seeds, granular materials | 1-5 tons/hour | 3-8 meters |

| Feed batching equipment | Feed ingredients, premixes | 5-50 tons/hour | 2-15 meters |

| Mixed feed production line | Feed formula, mixed feed | 10-100 tons/hour | 5-30 meters |

These data are examples only and actual conveyed materials, lift volumes and lift heights can be adjusted based on specific application requirements and equipment specifications. Feed bucket elevators can be customized according to the requirements of the production line to meet the needs of different industries and processes.

Xinxiang Dahan is a company specializing in the manufacture of feed bucket elevators, committed to providing high-quality, reliable and durable feed bucket elevators to meet customer needs in the fields of feed processing and production. Their products cover feed bucket elevators of different specifications and capacities to adapt to feed production lines of different sizes and requirements. The company's products have stable performance, reliable quality and wide application, and are recognized and trusted by customers inside and outside the industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.