It is a kind of equipment used for vertical transportation of bulk materials or powdery materials. It is designed to facilitate transportation and can be temporarily installed in various locations as needed.

![]()

![]()

Price::$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Particle size: 4-180(mm)

Delivery capacity: 10-830 (m³/s)

Large amount of material: 45-100 (mm)

Feed size: 90-150mm

Production capacity: 25-148m³/h

Application: It is widely used in scenarios that require temporary or mobile material lifting and transportation, such as grain harvesting and storage in the agricultural field, concrete mixing stations at construction sites, ore and aggregate transportation in mines and quarries, material loading and unloading in temporary storage facilities, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Portable bucket elevator, also known as a portable belt elevator or portable conveyor elevator, is a type of bucket elevator that is designed to be easily transported and installed in different locations. It offers the flexibility to move bulk materials vertically and horizontally, making it suitable for temporary or mobile applications.

1. Construction sites: materials such as gravel, sand, concrete, and construction waste can be transported from one location to another, assisting in the construction process, loading and unloading trucks, and facilitating site cleanup.

2. Agriculture and planting: used to perform tasks such as grain handling, seed handling, and agricultural product loading and unloading. They are used to efficiently transport crops, grain, seeds, fertilizers and other agricultural materials.

3. Warehousing and distribution: Can be used to load/unload trucks or containers, transfer packages or cartons between different areas of a facility, and optimize material flow in logistics operations.

4. Mining and quarrying: Can be used to transport ore, minerals, aggregates and other bulk materials from excavation sites to processing or storage areas.

fluidity

It can be easily transported to different locations as needed, allowing for a flexible material handling solution. This is especially beneficial for temporary projects, changing job locations, or situations where material handling needs may change.

Versatility

Versatile and can handle a variety of materials. They are commonly used in industries such as agriculture, construction, mining and manufacturing to transport grain, seeds, fertilizers, aggregates, powders and other bulk materials. Their adjustable height and reach capabilities allow them to adapt to a variety of applications.

Save space

Can be installed in confined spaces or areas where fixed installation is not possible or feasible. This makes them suitable for temporary facilities, confined spaces or situations where space is limited.

Easy to install and operate

They usually come with user-friendly controls and require minimal assembly. Their portability eliminates complex installation procedures, saving time and effort.

High cost performance

Portable models can be a cost-effective option compared to stationary bucket elevators. They are generally more affordable and have a lower initial investment. Additionally, their mobility enables efficient resource allocation as they can be moved and used in different locations or projects as needed.

Capacity flexibility

Portable bucket elevators are available in a variety of sizes and capacities to meet different material handling requirements. They can be customized to meet the specific needs of specific applications, providing flexibility in throughput and capacity.

The main difference between a portable bucket elevator and a fixed bucket elevator lies in their mobility and installation characteristics. Here are the key distinctions:

1.Mobility: A portable bucket elevator is designed to be easily transported and relocated to different job sites or within a facility. It is typically mounted on wheels or equipped with a trailer hitch, allowing for easy mobility. In contrast, a fixed bucket elevator is a stationary installation that is permanently installed at a specific location and is not designed for frequent relocation.

2.Installation: Portable bucket elevators are designed for quick setup and installation. They often feature a lightweight and compact design, adjustable legs, and simple connection points. This allows for rapid deployment and ease of installation in different locations. Fixed bucket elevators, on the other hand, require a more extensive installation process, including concrete foundations, structural support, and more permanent infrastructure.

3.Size and Capacity: Due to their portable nature, portable bucket elevators generally have smaller sizes and lower capacities compared to fixed bucket elevators. They are typically designed for lighter-duty applications and handling smaller volumes of materials. Fixed bucket elevators, on the other hand, can be larger in size and have higher capacities to accommodate the requirements of the specific application or facility.

4.Flexibility: Portable bucket elevators offer flexibility in adapting to different job site requirements. They often have adjustable height and length features, allowing for customization based on the material transfer heights and distances at various locations. Fixed bucket elevators, once installed, offer less flexibility in terms of height and location adjustments.

5.Application and Usage: Portable bucket elevators are commonly used for temporary or mobile material handling needs. They are suitable for industries where material transfer requirements change frequently or where permanent installations are not feasible or cost-effective. Fixed bucket elevators, on the other hand, are designed for long-term and continuous operation at a specific location, providing a reliable and efficient solution for vertical material transportation.

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

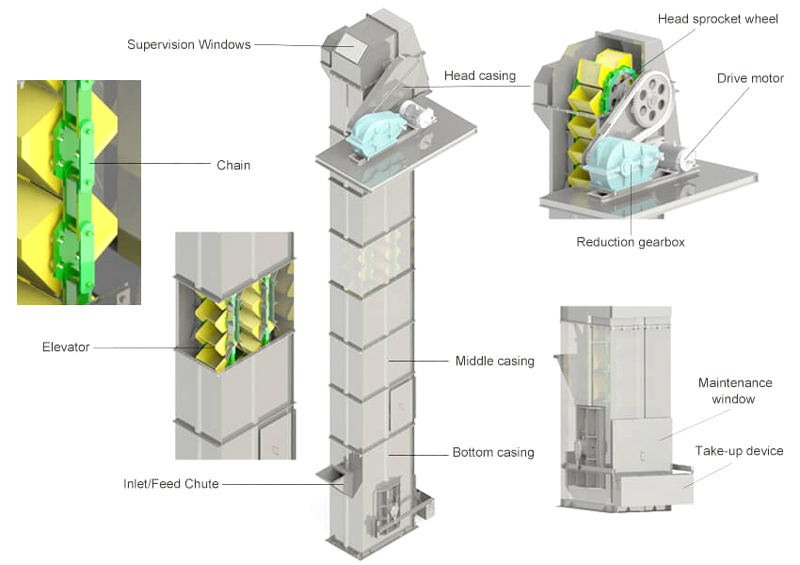

1.Frame: The frame of a portable bucket elevator would be designed to provide structural support and stability while allowing for easy transportation and relocation. It would typically be constructed using lightweight and durable materials such as aluminum or steel. The frame might feature adjustable legs or support points to accommodate different ground conditions and facilitate leveling during installation.

2.Bucket Assembly: The bucket assembly would consist of a series of buckets attached to a belt or chain. The buckets are typically made of robust materials like plastic or metal to withstand the weight and abrasion of the transported materials. They are spaced apart at regular intervals to form a continuous vertical or inclined conveyor path.

3.Belt or Chain: A portable bucket elevator would employ a belt or chain mechanism to move the buckets along the vertical or inclined path. The belt or chain would be selected based on the specific application requirements, considering factors such as the material being handled, capacity, and operating conditions. The belt or chain would be driven by a motorized pulley or sprocket system, providing the necessary power for the vertical transportation of materials.

4.Drive System: The drive system of the portable bucket elevator would typically consist of an electric motor, gearbox, and associated components. The motor provides the power to drive the belt or chain, moving the buckets along the elevator's path. The drive system may offer adjustable speed settings to control the material flow rate and adapt to different operational needs.

5.Discharge Chute: At the top or bottom end of the portable bucket elevator, there would be a discharge chute where the material is released from the buckets. The discharge chute may feature adjustable deflectors or gates to control the material flow and direct it to the desired location or subsequent processing equipment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.