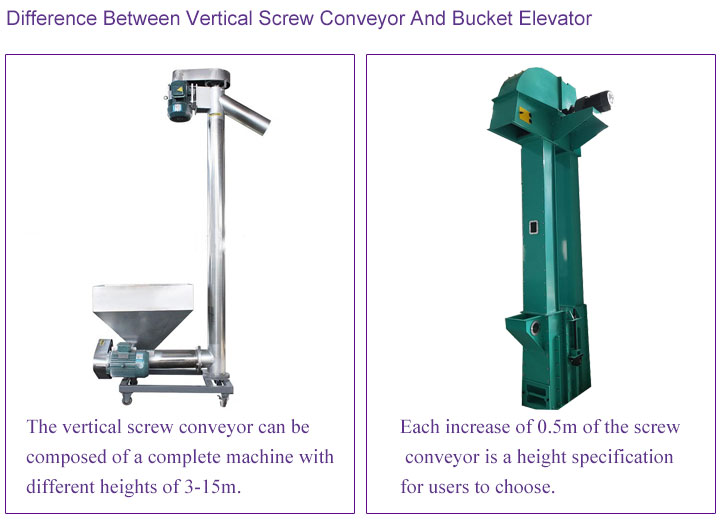

Both the vertical screw conveyor and the vertical bucket elevator are used to transport materials in the vertical direction, so what is the difference between the two, the following is the relevant introduction:

The spiral speed of the vertical screw conveyor is higher than that of the ordinary Screw conveyor. The material friction with the shell under the action of centrifugal force, the friction prevents the rotation of the material and the screw blade, overcomes the gravity of the material falling, and realizes the vertical transportation of the material.

The bucket elevator uses a hopper to scoop up the material from the storage below, and lift the material to a moving position along with the conveyor belt or chain. The hopper will turn over, so as to achieve the purpose of lifting materials.

Vertical screw conveyors can lift a variety of bulk materials on very steep slopes or completely vertical for transferring powder or granular materials from low to high. Bulk material taken from a silo, hopper, conveying or feeding device can be discharged via a vertical screw into a weighing hopper, one or more silos or silos, or another conveyor or conveying system.

Bucket elevators are used to vertically lift grains and similar dry, powdered, non-abrasive, non-packaging materials with particle sizes up to 13mm, from dry dusty powders such as fly ash to iron ore particles and more Various materials for heavy materials.

Vertical screw conveyor for conveying feed

Bucket elevator for lifting sand

Vertical screw conveyors are used to lift/load powder to the desired height for filling hoppers and/or silos, up to 8 meters, when increased lift heights are required, intermediate hangers or stabilizer bearings are usually required to eliminate excessive Spiral deflection and "whipping".

Bucket elevators are specially designed for vertical lifting of grain and similar materials, with discharge heights up to 44 m (144 ft) and throughputs up to 1,600 m 3 /h (942 cfm).

Compared with the price of the vertical screw conveyor and the bucket elevator, the cost of the bucket elevator is about 1.5 times higher than that of the vertical screw conveyor.

The above is about the main difference analysis of the bucket elevator of the vertical screw conveyor.

Welcome to our articles page! If you are interested in the differences between vertical screw conveyors and vertical bucket elevators that we have discussed, and would like to learn more about related products, we recommend that you click on the link below to enter our carefully prepared product page.

Are you still worried about whether to choose a vertical screw conveyor or a vertical bucket elevator? Click below to enter the product introduction page and learn more!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.