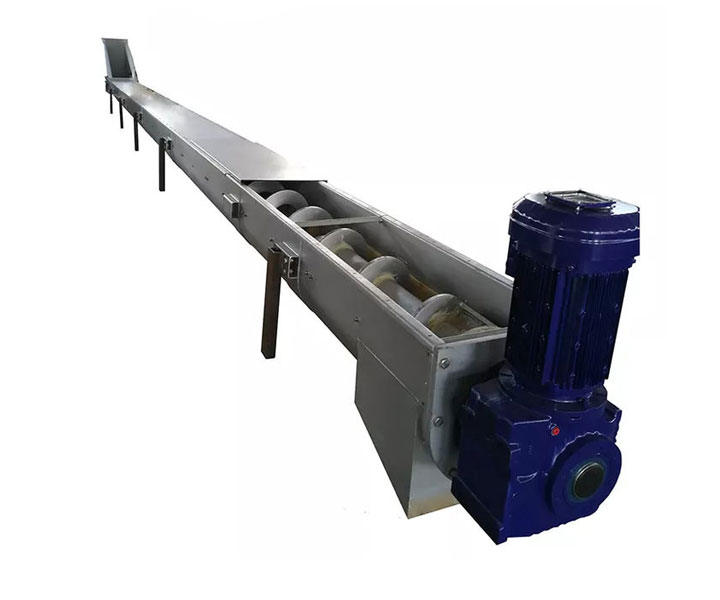

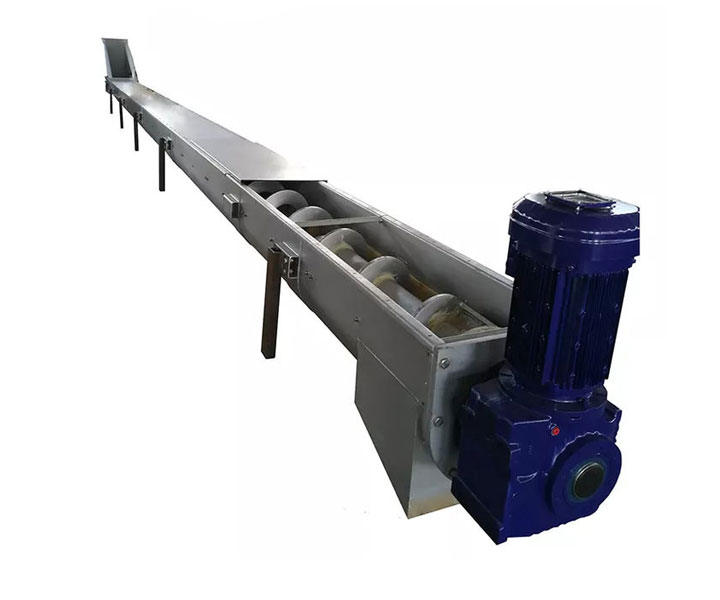

Commonly used for conveying sludge, mud or other viscous materials in sewage treatment plants and industrial environments.

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 150 - 470 mm

Length: 0-20 mt or 0-30 mt

Capacity: from 0.8 mc/h to 45 mc/h

Inclination of installation: 0-20°

Material: Carbon steel or stainless steel

Application: specifically designed for handling various types of sludge, such as wastewater sludge, industrial sludge, or other viscous materials.

Sludge shaftless screw conveyor is specially designed to handle wet, sticky or viscous materials such as sludge or mud and can convey them efficiently without clogging.Unlike traditional shaft-driven screw conveyors, shaftless screw conveyors eliminate the need for a central shaft, reducing maintenance costs and improving reliability.

It has a wide range of applications in sewage treatment, industrial production and other fields. Let's take a closer look at its application scenarios:

1. Sewage treatment plant: used to transport concentrated sludge to belt filter press, centrifugal dehydrator and other equipment for dehydration, and can also transport sludge to sludge drying bed, incinerator and other places for final disposal.

2. Food processing plant: transport residues produced by meat processing and vegetable processing or transport sludge produced by food processing.

3. Chemical plant: transport various sludges produced in the chemical production process, such as dye production waste liquid, petrochemical sludge, etc.

4. Paper mill: transport pulp produced in the papermaking process or fiber in papermaking wastewater, etc.

Below is a more detailed table showing the specific applications of sludge shaftless screw conveyors in conveying sludge:

| Sludge moisture content | Applications | Applications |

| High moisture content (>90%) | Sewage treatment plants | Transporting sludge, sewage, sludge mixture, etc. |

| Mining and metallurgical industries | Transporting wet slag, coal slag, etc. | |

| Food processing plants | Transporting liquid food wastewater or solid waste. | |

| Pulp and paper industries | Transporting wet pulp waste or waste pulp. | |

| Medium moisture content (70-90%) | Municipal sludge treatment plants | Transporting sludge with moderate wetness. |

| Chemical industries | Transporting moderately wet chemical waste. | |

| Agriculture | Transporting agricultural waste or fermented organic matter. | |

| Low moisture content (<70%) | Sludge drying plants | Transporting dried sludge solid materials. |

| Garbage treatment plants | Transporting dried solid waste. |

Shaftless Design

Unlike traditional screw conveyors, the shaftless design eliminates the central shaft, allowing for the conveyance of sticky and tangled materials without blockages.

Handling Viscous Materials

This conveyor is specifically designed to handle materials that are wet, sticky, or viscous, such as sludge or slurry, and can effectively transport them without clogging.

Continuous Operation

The screw conveyor facilitates continuous and reliable material transport, ensuring a smooth flow of materials along its length.

Low Maintenance

Due to the shaftless design, there are fewer components that can wear or require maintenance, resulting in reduced downtime and maintenance costs.

Sealed and pollution-free

The gasketed tank cover ensures that the tank body and the tank cover are sealed to prevent material leakage and odor leakage.

Long service life

The blade thickness is not less than 20mm, and the spiral blade height is not less than 80mm, which can greatly extend the service life.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

Sludge shaftless screw conveyor is a kind of efficient sludge conveying equipment. Its main features are no bearings, good conveying effect, stable operation, and can be designed and customized according to different needs. Our company once cooperated with a sewage treatment plant to use sludge shaftless screw conveyor for sludge transportation and treatment, and the effect is very remarkable. After pre-treatment, the sludge is transported to the sludge treatment machine, and the rotation of the shaftless screw conveyor transports the sludge from the starting point to the end point, compresses and dehydrates it, and finally forms a dry solid. The operation effect of the equipment is reliable, and the operation is simple, which greatly improves the processing efficiency and work effect, and has been well received by customers.

When choosing a shaftless screw conveyor for sludge, there are several key considerations to consider:

1. Sludge characteristics: Determine the water content of the sludge to select the appropriate conveyor design. Understanding the physical characteristics of the sludge affects the conveying efficiency and design.

2. Conveying distance and height: Determine the conveying level and height from the ground to select the appropriate machine length and inclination angle (generally, the inclination angle of conveying sludge should not exceed 30 degrees).

3. Conveying capacity: Calculate the required conveying capacity based on production needs to ensure that the equipment can meet the flow requirements.

4. Material selection: Select appropriate materials such as stainless steel or alloy materials based on the corrosiveness and abrasiveness of the sludge.

5. Installation space: Ensure that there is enough installation space and consider the size and layout of the equipment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.