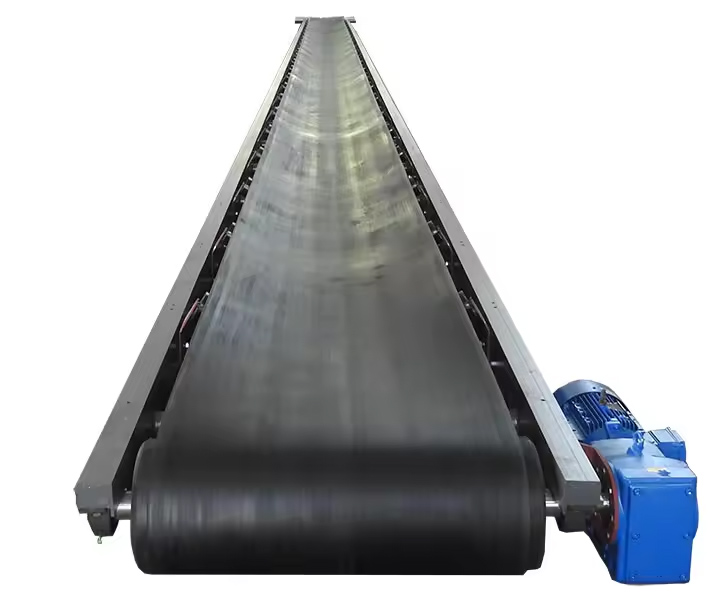

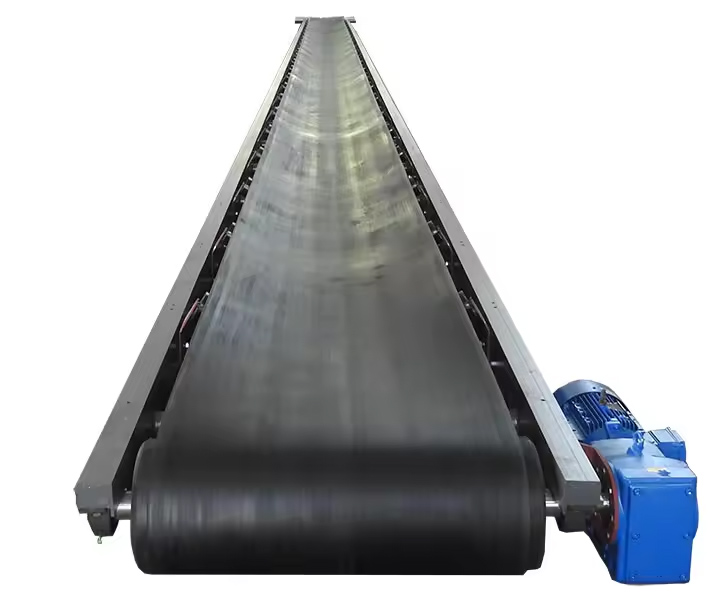

Can handle solid materials such as waste, gravel, pebbles, dry sludge, etc. from construction sites, storage tanks and buildings.

![]()

![]()

Price::$680.00 - $22,800.00/Set

Consult now and enjoy a 10% discount

Belt width: 300-1500mm

Belt Type: Skirt

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

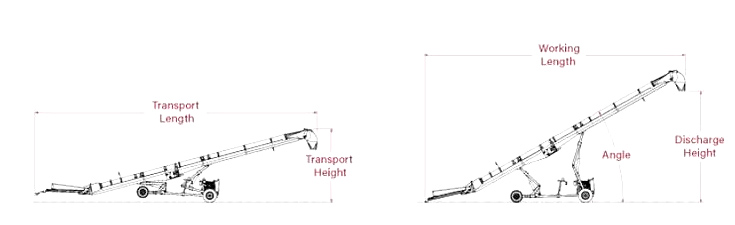

Conveying length: 6 meters

Belt material: food grade PVC, PU, rubber

Conveying angle: 0-90°

Weight: 300 kg

Application: Used to convey various types of construction waste including debris, rubble, aggregate, bricks, concrete, wood, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

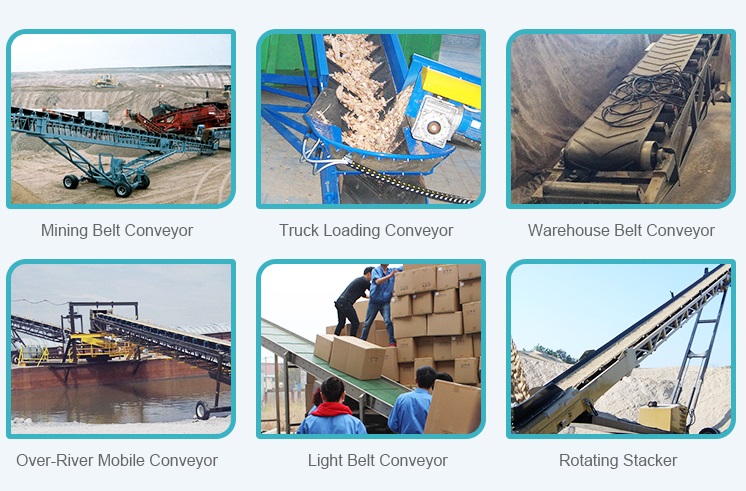

Belt conveyor for construction waste is a type of material handling equipment used to transport and transfer construction waste materials from one location to another. It plays a crucial role in managing and disposing of construction waste efficiently and effectively. Belt conveyors are effective for handling various types of construction waste materials such as debris, rubble, soil, gravel, sand, and other waste materials generated during construction activities.

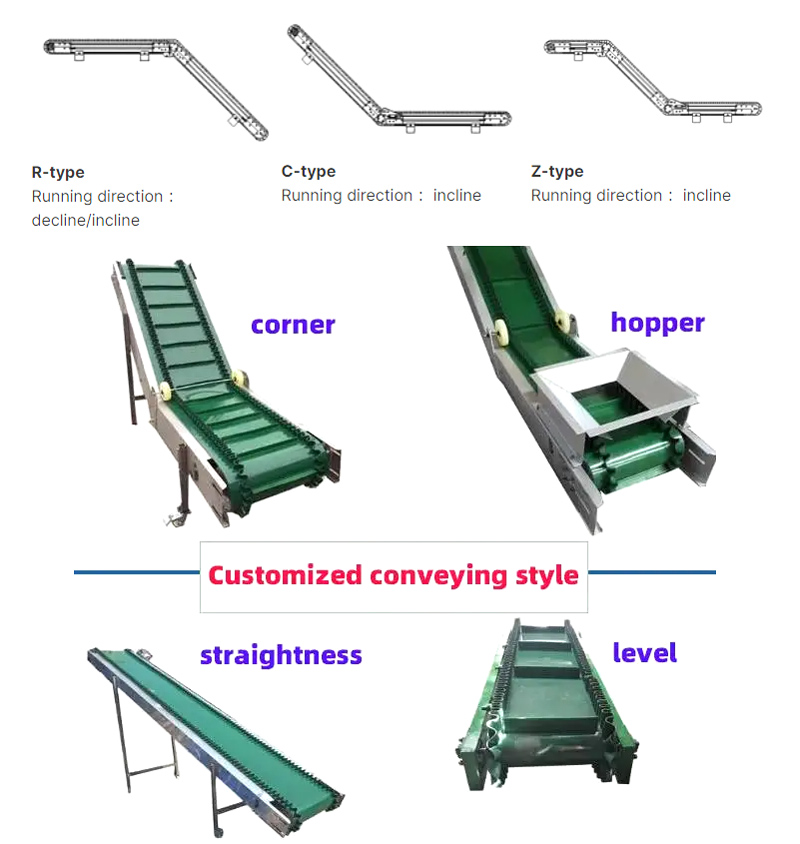

Belt conveyor for construction can be configured to suit the specific layout and requirements of the construction site. They can be straight, curved, inclined, or declined, allowing for efficient material transfer around obstacles, buildings, or uneven terrain.

The application of a conveyor belt for construction waste is widespread in various stages of construction projects and waste management processes. Here are some common applications:

1. Construction sites: On construction sites, belt conveyors can be used to transport construction waste from the construction site to garbage disposal areas or recycling sites. This helps keep the job site clean, improves work efficiency, and ensures waste materials are properly disposed of.

2. Demolition projects: In demolition projects, belt conveyors can be used to quickly and efficiently transport waste, gravel, concrete fragments and other materials from demolished buildings to designated processing or recycling sites.

3. Earthmoving: In earthmoving, belt conveyors can be used to transport excavated soil, gravel and other materials from the excavation area to the stacking area, or to use these materials for landfill or backfill.

4. Construction waste recycling station: At construction waste recycling sites, belt conveyors can be used to sort and classify different types of construction waste according to type and transport them to corresponding processing facilities or recycling sites.

5. Construction waste landfill: In construction waste landfills, belt conveyors can be used to transport construction waste from the unloading area to the landfill area for landfill disposal.

Efficient Transportation

Belt conveyors are designed to handle heavy loads and can transport construction waste materials over long distances. They have high load-carrying capacities and can move large volumes of waste quickly, reducing the time and effort required for manual handling.

Versatile Application

Belt conveyors can handle various types of construction waste materials, including debris, rubble, aggregates, bricks, concrete, wood, and more. They can be used in different construction sites, demolition projects, recycling facilities, and waste management centers.

Flexibility in Layout

Belt conveyors can be configured to suit the specific layout and requirements of the construction site. They can be straight, curved, inclined, or declined, allowing for efficient material transfer around obstacles, buildings, or uneven terrain.

Adjustable Speed and Control

Belt conveyors offer speed control options, allowing operators to regulate the conveyor's movement according to the required transportation speed and material flow rate. This flexibility enables optimal handling and prevents overloading or material spillage.

Minimizes Manual Handling

By utilizing a belt conveyor, manual handling of construction waste can be significantly reduced, minimizing the risk of injuries and improving workplace safety. Workers can focus on other tasks rather than physically moving heavy or bulky waste materials.

Durability and Low Maintenance

Belt conveyors are built to withstand harsh construction environments and heavy-duty usage. They are constructed with robust materials, such as steel or reinforced rubber, and require minimal maintenance, resulting in long-term cost savings.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

Construction waste belt conveyors can be powered by electric motors, or be part of a larger conveyor system powered by a central drive unit. It can be configured with various functions and accessories to meet the specific requirements of construction waste treatment, such as:

Inclined sections: Can be designed with inclined sections to facilitate movement of debris from lower levels to upper levels, for example when loading debris onto trucks or containers.

Side Skirts and Containment Systems: These features help contain and prevent spillage of construction debris, ensuring a cleaner, safer work environment.

Sorting Mechanisms: Optional sorting mechanisms such as screens, separators or magnetic systems can be incorporated into the conveyor to sort and separate different types of construction waste.

Loading Hoppers or Chutes: These devices are used to facilitate the loading of construction waste onto conveyors, allowing workers to efficiently deposit debris.

Safety Features: Construction waste belt conveyors may include safety features such as emergency stop buttons, safety guards, and audible or visual alarms to keep workers safe during operation.

| Client's name | Convey products | Purpose of usage | Conveying capacity | Conveying length |

| India**Construction Company | Construction waste, concrete fragments | Clean up construction site | 30 tons/hour | 12 meters |

| Italian ** Demolition Company | Demolition scrap, bricks, wood | Building demolition projects | 17 tons/hour | 9 meters |

| Australian ** Recycling Center | Construction waste, metal, concrete | Waste sorting and recycling | 3 tons/hour | 6 meters |

| South Africa ** Construction Company | Dirt, gravel, sand | Transportation of materials to construction area | 10 tons/hour | 10 m |

| **Waste Disposal Company in the United States | Construction waste, non-recyclable materials | Waste disposal and landfill | 5 tons/hour | 4 meters |

Xinxiang Dahan is a manufacturer specializing in the production of belt conveyor equipment. Its products are mainly used in construction sites and waste management fields. The company is committed to providing high-quality, high-efficiency belt conveyor solutions to meet customers' needs in construction waste treatment and management. Xinxiang Dahan's belt conveyor products have the characteristics of high reliability, stable operation, and easy operation. They are widely used in construction sites, demolition projects, earthworks, environmental protection projects, etc., helping customers achieve fast, safe, and efficient processing of waste materials. transportation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.