In the realm of industrial operations, the efficient handling and transport of sludge and waste materials are essential for optimizing processes, reducing environmental impact, and promoting sustainability. Belt conveyors play a vital role in facilitating the movement of sludge and waste within various industries, offering a reliable and cost-effective solution for material transport.

Belt conveyors for sludge and waste transport are widely used in industries such as manufacturing, recycling plants, wastewater treatment facilities, and mining operations. These conveyors play a crucial role in streamlining material handling processes, improving operational efficiency, and enhancing overall productivity within industrial settings.

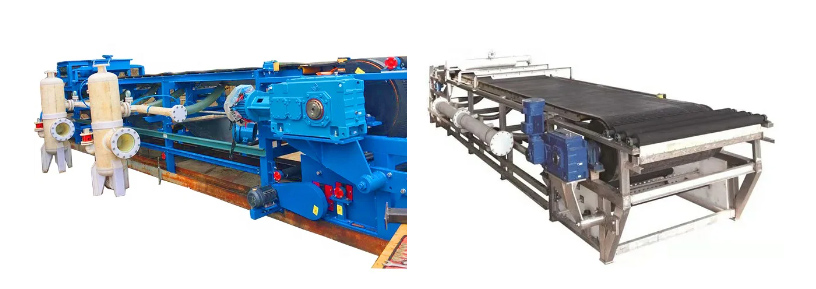

Belt conveyors are commonly used for sludge and waste transport due to their efficiency, versatility, and ease of operation. They offer several benefits in handling sludge and waste materials:

Efficient Transportation: Belt conveyors are designed to handle bulk materials efficiently. They can transport large volumes of sludge and waste over long distances, making them suitable for applications where continuous and reliable transportation is required.

Versatility: Belt conveyors can handle various types of sludge and waste materials, including municipal solid waste, construction and demolition waste, industrial waste, and more. This versatility allows them to be used in a wide range of industries, such as waste management facilities, recycling plants, construction sites, and manufacturing facilities.

Customization Options: Belt conveyors can be customized to meet specific requirements. They can be designed with different belt widths, lengths, and configurations to accommodate the volume and characteristics of the sludge or waste material being transported. Additionally, accessories such as covers, side guides, and discharge chutes can be added to optimize the conveyor's performance.

Gentle Handling: Sludge and certain waste materials can be delicate or prone to breakage. Belt conveyors provide a gentle and controlled method of transportation, minimizing the risk of material degradation or spillage. This helps maintain the integrity of the sludge or waste throughout the transport process.

Easy Maintenance: Belt conveyors are relatively easy to maintain. They typically have simple designs with fewer moving parts, reducing the likelihood of mechanical failures. Routine maintenance tasks such as belt replacement, cleaning, and lubrication can be performed efficiently, minimizing downtime.

Cost-Effective: Belt conveyors offer a cost-effective solution for sludge and waste transport. They have lower operating costs compared to other transportation methods, and their energy efficiency helps reduce power consumption. Additionally, their durability and longevity make them a reliable long-term investment.

In summary, belt conveyors are well-suited for the transport of sludge and waste materials, providing efficient, reliable, and customizable solutions for various industries involved in waste management and disposal.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.