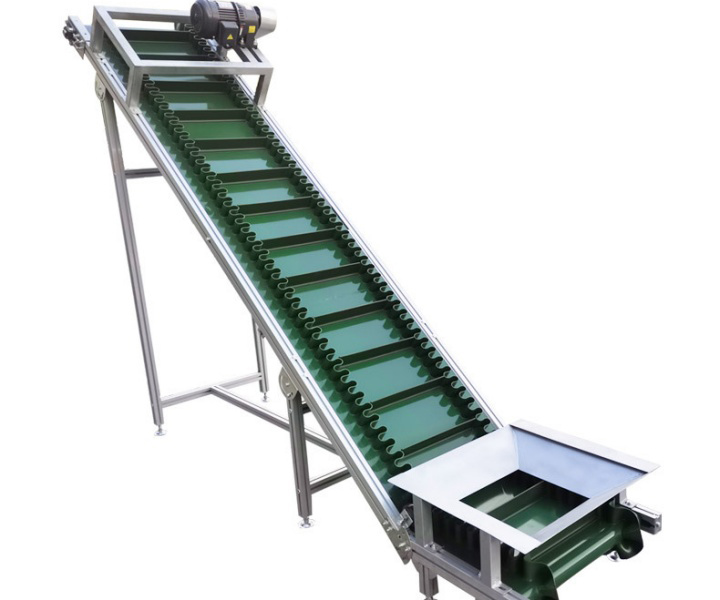

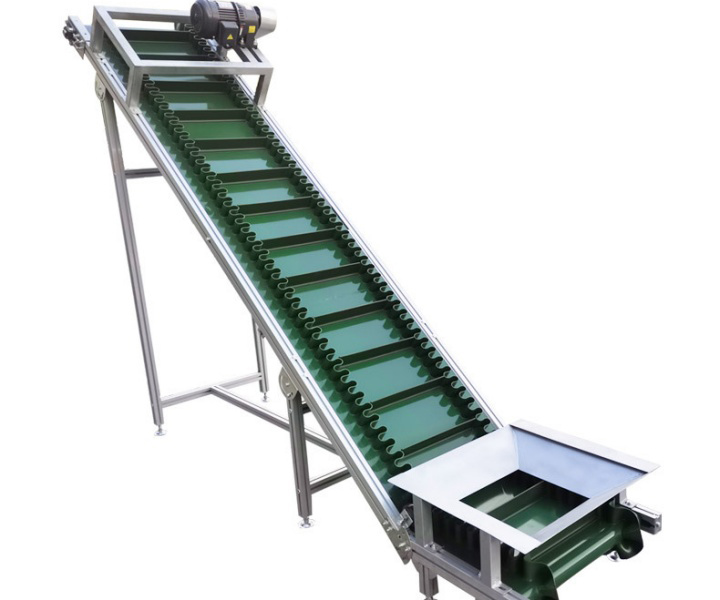

Equipment specially designed for salt transportation, using belt drive, can be used in salt mining, salt drying fields, salt factory production lines and other occasions.

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Belt width: 400-2400mm

Speed: 0.8-4.0m/s

Conveying capacity: 30-3000t/h

Conveying length: <132meters

Conveying angle: 0-90°

Frame material: Rubber、PVC

Application: It is suitable for the transportation and processing of salt, and can be used in salt mining, salt drying fields, salt factory production lines and other occasions.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Belt conveyor for salt is a type of conveyor system specifically designed for the transportation and handling of salt or salt-related products. It consists of a continuous belt, typically made of durable materials such as rubber or PVC, that moves along a series of rollers or pulleys. The belt is driven by a motorized pulley or a drive unit, which propels the belt and facilitates the movement of salt along the conveyor.

Belt conveyors for salt facilitate the efficient and reliable transportation of salt in various industries. They ensure smooth material flow, minimize manual handling, and maintain product integrity. Whether it's in food processing, chemical manufacturing, or other applications, belt conveyors designed for salt play a vital role in optimizing production processes and ensuring the safe and efficient handling of this essential mineral.

A belt conveyor for salt is commonly used in both bulk salt and bagged salt conveying applications. Here's how it is applied in each scenario:

1.Conveying Bulk Salt:

Mining and Extraction: In salt mines, belt conveyors transport bulk salt from the mining site to processing plants or storage facilities. The conveyor system efficiently moves large quantities of salt, facilitating extraction and transportation processes.

Salt Processing: Belt conveyors are employed in salt processing plants to transport bulk salt between different stages of the production process. This includes conveying salt from storage silos to crushers or grinding mills, from mills to screening equipment, and from screening to packaging or storage areas.

Salt Storage and Stockpiling: Belt conveyors are utilized to transport bulk salt from processing plants to storage facilities or stockpiles. The conveyors ensure a continuous and controlled flow of salt, allowing for efficient storage and inventory management.

Salt Distribution: Belt conveyors play a crucial role in the distribution of bulk salt. They transport salt from storage or stockpile areas to loading points, where it is loaded onto trucks, railcars, or ships for distribution to various destinations.

2.Conveying Bagged Salt:

Packaging Facilities: Belt conveyors are used in salt packaging facilities to transport bags of salt from packaging machines to sealing or labeling stations. The conveyors ensure a smooth flow of bagged salt, optimizing packaging processes and reducing manual handling.

Distribution Centers: In salt distribution centers, belt conveyors are employed to handle bagged salt within the facility. They transport bags of salt to storage areas, loading docks, or sorting stations for further distribution to retail outlets or end consumers.

Retail Outlets: Belt conveyors may be used in retail environments to move bags of salt from storage areas to the point of sale. This aids in restocking shelves and ensuring a continuous supply of bagged salt for customers.

The conveyor belt is driven by a driving device to transport salt products from one location to another. When the conveyor belt starts running, the salt products are placed on the conveyor belt, and as the conveyor belt moves, the salt products are continuously transported to the destination. The driving device is usually an electric motor or a hydraulic motor, which transmits power to the conveyor belt through a transmission device to drive it to run. The tensioning device is used to maintain the tension of the conveyor belt to prevent slack or deviation.

Efficient and reliable transportation:

Provides a reliable and efficient method of transporting salt from one location to another. They can process large quantities of salt continuously, ensuring a smooth and consistent flow throughout.

Increased productivity

Automated and continuous transport of salt can be achieved without manual handling or reliance on other slower transport methods.

Flexibility and Versatility

Belt conveyors can be designed and customized to suit different salt handling applications, including bulk or bagged salt. They can be adapted to various layouts, tilts and operational requirements.

Dust control

Belt conveyors can be equipped with dust containment systems such as enclosures, hoods or dust extraction devices to minimize the release of salt particles into the surrounding environment.

Corrosion resistance

Salt is corrosive, and belt conveyors designed for salt applications are made of corrosion-resistant materials. This ensures the longevity and durability of the delivery system.

Large-capacity transportation

Can carry a large amount of salt products and achieve large-capacity transportation, and is suitable for production scenarios that require large-volume transportation.

Belt conveyor for salt is mainly composed of a conveyor belt, a driving device, a tensioning device, a supporting device and a guiding device.

Conveyor belts are usually made of wear-resistant and high-temperature-resistant materials to meet the transportation needs of salt products.

The driving device drives the conveyor belt through an electric motor to realize continuous transportation of salt products.

The tensioning device is used to maintain the proper tension of the conveyor belt to ensure smooth operation of the conveyor belt.

The support device supports the conveyor belt to ensure that the conveyor belt remains stable during operation.

The guide device is used to guide salt products not to deviate from the direction during transportation.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

The capacity and length of salt belt conveyors can be customized to meet specific requirements. Here are some factors and considerations to consider when customizing the capacity and length of your salt belt conveyor:

Material Properties: Factors such as bulk density, particle size, moisture content and flowability of the salt all affect the capacity of the conveyor.

Throughput Requirements: The desired salt throughput or production rate is a key factor in customizing belt conveyor capacity. It involves determining the amount of salt to transport within a certain time frame. This information assists in selecting the proper belt width, speed and overall size of the conveyor system.

Belt width and speed: Increase the belt width to transport more salt. Likewise, adjusting the belt speed can help achieve the desired throughput. However, it must be ensured that the belt width and speed are within the operational limits of the conveyor system and do not compromise its reliability and performance.

Conveyor Length: The length of the belt conveyor is determined by the distance between the start and end of the salt delivery. Depending on the layout of the facility and the space available, the conveyor length can be customized to optimize the salt handling process.

Incline or Incline Angle: Steeper inclines or declines may require additional design considerations to ensure proper belt tension, material containment, and overall system stability.

Operating environment: The operating environment, including temperature, humidity, and potentially corrosive elements, also plays a role in customizing the capacity and length of your belt conveyor.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.