Its side guard device can prevent material from overflowing and is suitable for conveying various materials.

![]()

![]()

![]()

Price:$499.00-$6,000.00/Set

Consult now and enjoy a 10% discount

Conveying capacity: 30-3000m³/h

Conveying speed: 1.25-2.0m/s

Conveying length: 10 meters

Conveying Angle: 0°-90°

Belt width: 400-2400mm

Material: Carbon Steel/Stainless Steel

Application: Sidewall belt conveyor is widely used in mining, construction, metallurgy and other industries. In mines, it can be used to transport raw materials such as coal and ore.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

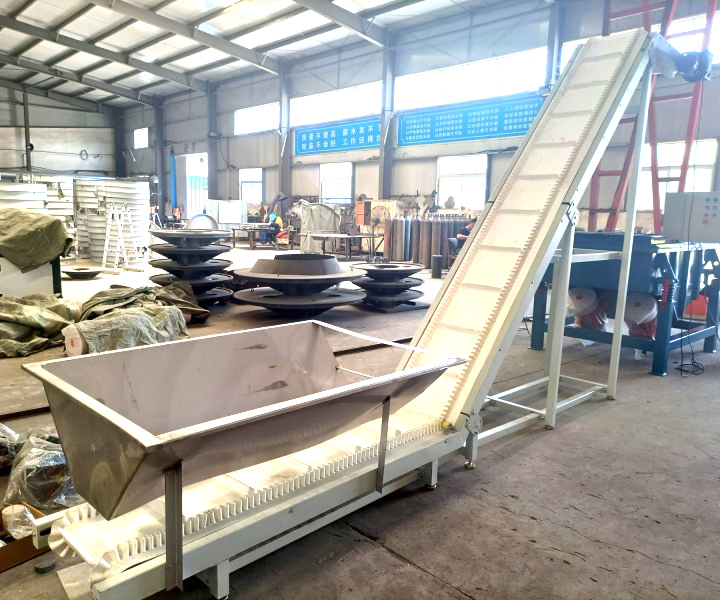

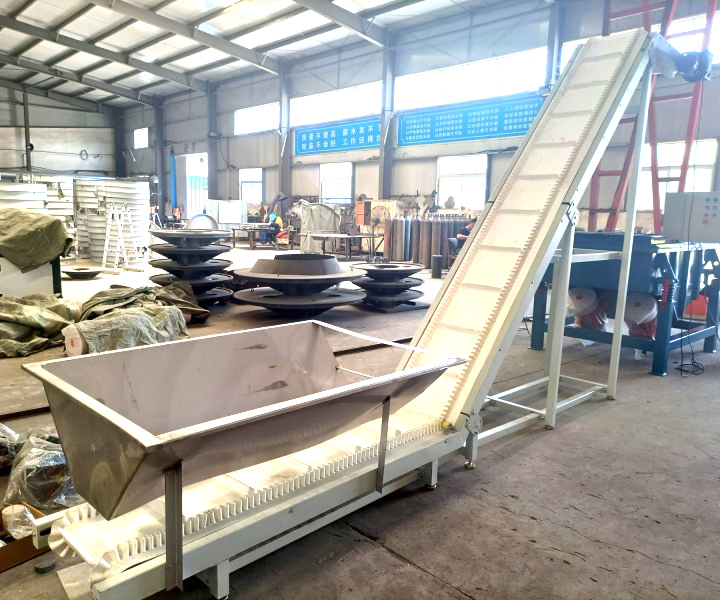

Sidewall belt conveyor, also known as a high angle conveyor, is a type of conveyor system that is designed to transport materials at a steep angle or vertically, while also preventing material from spilling over the sides of the conveyor belt. The sidewalls of the belt are made of flexible material, such as rubber or PVC, and are designed to provide a barrier that keeps materials contained during transport.

The design of a sidewall belt conveyor typically includes a belt with sidewalls that rise above the horizontal surface of the belt. The sidewalls can be customized to the specific application, including height, angle, and spacing. The belt is typically driven by a motor and pulley system and can be designed to operate at a range of speeds and capacities to meet specific production requirements.

Sidewall belt conveyors are widely used in various industries for conveying materials at large angles or vertically. Here are some common applications for side belt conveyors:

Mining industry: conveying bulk materials such as coal, ore and minerals. They are commonly used to transport materials from underground mines to the surface.

Agriculture: Used in agriculture to transport grain, seeds, and other agricultural products. They can be used to transport material from storage silos to processing facilities or from fields to warehouses.

Construction: Used in the construction industry to transport materials such as sand, gravel and concrete. They are often used to transport materials to high altitudes, for example during the construction of tall buildings.

Manufacturing: Used in manufacturing to transport materials during production. They can be used to transport raw materials, finished products and scrap.

Recycling: Used in the recycling industry to transport materials such as plastic, paper and metal. They can be used to transport materials from sorting facilities to processing facilities or from recycling centers to warehouses.

Sidewall belt conveyor is a continuous conveying equipment that conveys materials through the movement of the conveyor belt that carries the material, using the conveyor belt as the traction and bearing member. The conveyor belt is wound around the drive roller and the tail roller to form a carrier endless belt. The support is used to limit the deflection sag of the conveyor belt, and the tensioning device provides the necessary tension for the normal operation of the conveyor belt. When working, the driving device drives the transmission roller, and the conveyor belt is driven by the friction between the transmission roller and the conveyor belt. The material is mounted on the conveyor belt and moves together with the conveyor belt to complete the conveying of the material.

Large-angle transportation

designed for large-angle or vertical transportation of materials, very suitable for applications with limited space or long-distance transportation of materials.

Material containment

Designed with flexible side walls, it can contain materials during transportation to prevent overflow or material loss. This is especially important when handling fragile, hazardous or difficult to transport materials.

Versatility

Sidewall belt conveyors can be customized to handle a variety of materials, including bulk materials, powders and granules. They can also be designed to run at various speeds and capacities, making them versatile and adaptable to various production needs.

Reduced maintenance

Sidewall belt conveyors have fewer moving parts than other types of conveyor systems, reducing the need for maintenance and repairs. This reduces downtime and increases productivity.

Space efficiency

It is used to transport materials in a compact space, thereby effectively utilizing the floor area of the production facility. This makes them ideal for applications where space is limited.

Safety

The sidewall belt conveyor can be designed with safety functions such as emergency stop buttons, safety protection devices, and monitoring systems to ensure safe operation.

Inclined sidewall belt conveyor and Z-type sidewall belt conveyor are common sidewall belt conveyor types. The following is a detailed introduction to these two types of conveyors.

Inclined sidewall belt conveyor

When the conveying angle = 45°: When the conveying angle is 45°, the material will move at a relatively fast speed, which is suitable for occasions where fast material conveying is required.

When the conveying angle is 0°-45°: Within this range of conveying angles, the conveying speed of the material is relatively stable, which is suitable for industries that require stable conveying, such as granular material conveying and food processing.

When the conveying angle is 45°-90°: The conveying angle of the sidewall belt conveyor is large, allowing the material to be conveyed at a larger slope. It is common in industrial fields that require fast and efficient material conveying, such as coal mines, building materials, etc.

Z-type sidewall belt conveyor

Z-type sidewall belt conveyor is used to realize the conveying of materials between horizontal, vertical and horizontal directions. This design provides convenience in occasions where the conveying direction needs to be changed.

In the initial stage, the material enters the conveyor from a horizontal position and moves along the horizontal conveying section. Convey the material from one position to another and maintain a horizontal state.

When the material reaches the position where it needs to be transported vertically, the conveyor belt starts to move upward, so that the material is transported upward in the vertical direction.

After the material reaches the highest point of vertical transportation, the conveyor belt switches to a horizontal state again and starts to continue transporting the material in the horizontal direction.

In some applications, sidewall belt conveyors are more efficient than other types of conveyor systems. The following is the difference between the sidewall belt conveyor and the ordinary belt conveyor:

| Compared | Sidewall Belt Conveyor | Other Belt Conveyors |

| Space Requirements | Can be configured to transport material vertically, horizontally or at an incline, this flexibility allows efficient use of space. | May only convey product horizontally or at a slight angle |

| Material Containment | Designed to prevent material from falling off the sides of the belt during transport. This is especially important for applications where spillage could cause a safety hazard or damage equipment. | When conveying products at a large angle, ordinary belt conveyors may easily fall and scatter when conveying products |

| Handling Capabilities | Can be designed to handle a wide variety of materials including bulk materials, powders and granules. They can also be designed to operate at certain speeds and capacities to meet specific production requirements. | Other types of conveyor systems, such as roller conveyors or screw conveyors, may not offer the same level of material holding capacity. |

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

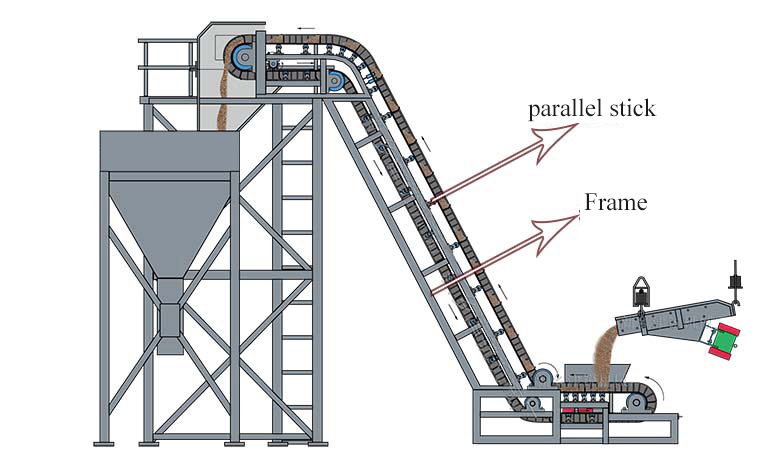

Sidewall belt conveyor consists of corrugated sidewall belt, base belt diaphragm, head drive roller, drive device, reversing pressure roller, sidewall roller, rapper and so on.

Belt: There are PP plastic module belt, PVC green belt, PVC baffle belt or PU belt.

Sidewall: designed to be corrugated to prevent the material from slipping and falling.

Diaphragm: The main function is to support materials, which can be divided into two categories: fixed type and detachable type.

The ribs and the diaphragm are connected with the base tape by the method of secondary vulcanization, which has a high connection strength.

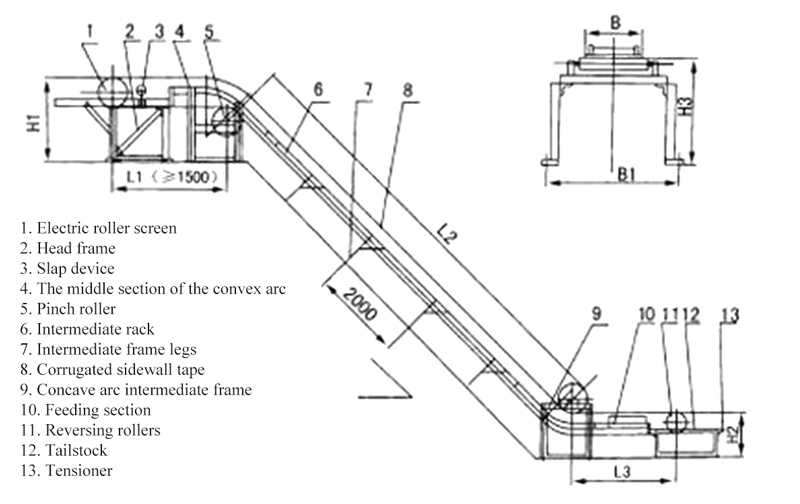

In order to obtain better material receiving and unloading conditions, the sidewall belt conveyor adopts a "Z" shape arrangement. That is to say, there is an upper horizontal section, a lower horizontal section and an inclined section, and the material is received in the lower horizontal section and discharged in the upper horizontal section. The upper horizontal section and the inclined section are connected by a convex arc section frame, and the lower horizontal section and the inclined section are connected by a concave arc section frame to realize the smooth transition of the conveyor belt.

Upper horizontal section: In order to meet the requirements of different discharge heights, the head frame is divided into low head frame (head frame height H0=1000mm), Chinese head frame (head frame height H0=1100~1500mm) and high head frame ( Head frame height H0=1600~2000mm). And correspondingly, the upper horizontal section is equipped with low-type convex arc section frame and low-type middle frame support legs (with head frame height H0=1000mm), Chinese type convex arc section frame and middle type middle frame support legs. (with head frame height H0=1100~1500mm), high convex arc section frame and high middle frame support legs (with head frame height H0=1600~2000mm).

Inclined section: No matter whether the upper horizontal section adopts the low-type, middle-type or high-type intermediate frame legs, the inclined section adopts the low-type intermediate frame legs. When the inclination angle of the conveyor is β≧45°, it is recommended to use the type II low-type intermediate frame outriggers.

Lower horizontal section: The lower horizontal section adopts low intermediate frame legs.

A mining company introduced a sidewall belt conveyor for conveying coal and ore. The sidewall design effectively prevents material spillage, improving safety and production efficiency. The equipment performed well in the production process, reducing material waste and cleanup work, and improving the working environment. The company thus saved costs and improved production efficiency. The customer was satisfied with the stability and performance of the equipment, and it became an indispensable part of the company's production chain.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.