Compared with the roller conveyor, the Small Belt Conveyor does not have so many restrictions on the size and flatness of the goods. Because of its smooth operation and no gap between the roller conveyor, it has great advantages in conveying small pieces. Natural advantages, so it is widely used in the delivery of small packages and small items. However, does this mature and reliable product have no pain points in application? This is not always the case. From the point of view of the power source alone, there are some unsatisfactory places:

1. When it uses a traditional motor as a drive, because the motor is externally suspended, it occupies a relatively large space. In some occasions where the space is relatively small, it is facing a lot of trouble;

2. When it uses the AC electric roller as the drive, the space problem is solved, but since most of the AC electric rollers are oil-cooled, if the tension control of the belt is not good, the electric roller will produce In the case of overload, after running for a period of time, the axis of the roller will be deformed, which will affect its oil seal, resulting in oil leakage, which will affect the environment on site. Especially some food hygiene industries are most sensitive to this one; some places that need to be weighed or where people work, need to start and stop frequently, which is also a test for AC electric rollers;

1. Compared with the traditional motor drive structure, its structure is relatively simple. The elastic belt only needs to be pre-tensioned, and the default is to prevent deviation, and the corresponding structure is omitted;

2. Compared with the structure driven by AC electric roller, it can start and stop frequently, and the range of speed regulation is relatively large, and the oil leakage problem caused by belt tension can also be solved;

3. For very short belt conveyors, the belt deviation problem caused by the small aspect ratio can be well solved;

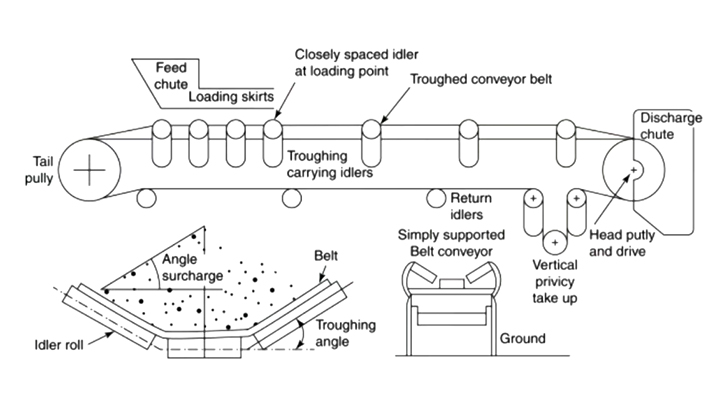

The design principle of small belt conveyor is basically similar to that of traditional belt conveyor, but it is smaller in size and suitable for environments with limited space. The following is the design principle of small belt conveyor:

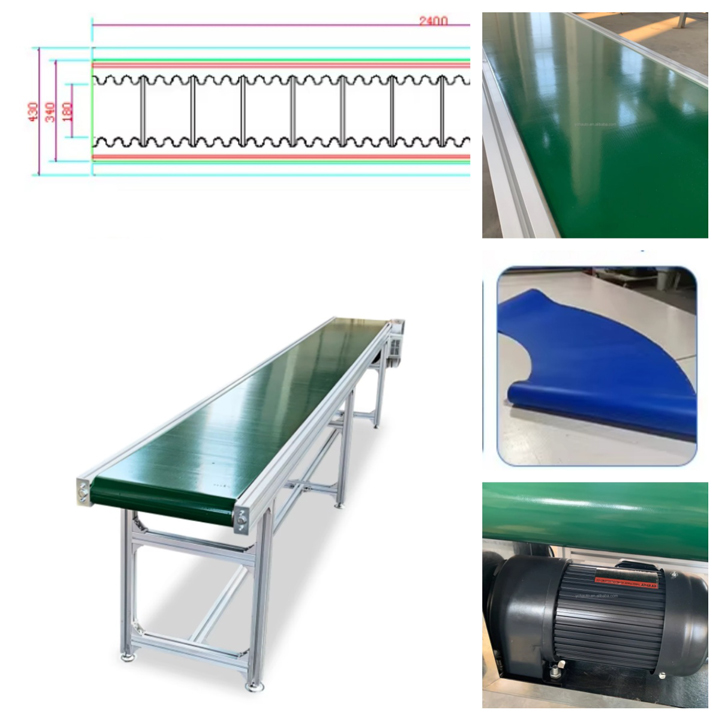

Conveyor belt: Conveyor belt is usually made of rubber, polyvinyl chloride (PVC), polyurethane and other materials, and is an important product in conveying equipment.

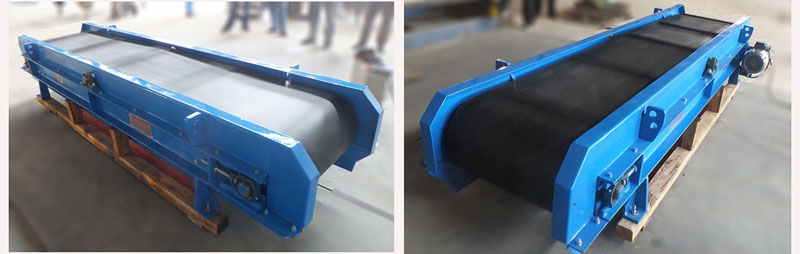

Drive device: The main drive device is equipped with a motor, reducer, etc., which is used to drive the conveyor belt to run.

Support structure: The conveyor belt needs to be supported during operation. The support structure is usually composed of a frame and support columns to ensure the stable operation of the conveyor belt and the safe transportation of materials.

Guide device: Prevent materials from deviating from the track or accumulating on the conveyor belt during transportation.

Safety device: In order to ensure safe use, small belt conveyors should also be equipped with safety devices, such as emergency stop switches, protective covers, etc., to prevent accidents.

The following factors are usually considered when determining the size of the conveyor belt:

The nature of the conveyed material: First, the size, weight and conveying method (horizontal, inclined, etc.) of the conveyed material need to be considered.

Conveying capacity: Determine the amount of material to be conveyed, which will directly affect the conveyor belt and width.

Conveying distance and height: The length and height (how many degrees of inclination) of the conveyor belt are also important factors in determining the size.

Material characteristics: Select the material of the belt based on the characteristics of the material. Different materials will affect the quality of the material and the service life of the conveyor.

Layout and space limitations: Determine the layout and installation space of the conveyor belt, including the direction of the conveyor belt, the radius of the turning point, etc., to ensure that the conveyor belt can be installed and operated smoothly.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.