Belt conveyor is a common material conveying equipment. The inclination angle refers to the inclination of the conveyor belt relative to the horizontal line, which affects the conveying effect and conveying capacity of materials during the conveying process. The inclination angle of belt conveyors is usually between 0° and 90°. The tilt angle is determined based on comprehensive consideration of material properties, conveying distance, material flow and other factors.

The inclination angle is 15°:

Situation: The inclination angle of 15° is relatively small, suitable for conveying some easily flowing materials, and can effectively improve the conveying efficiency of materials.

Application scenarios: Suitable for conveying some granular or bulk materials in coal mines, building materials, chemical industry and other industries.

The inclination angle is 30°:

Situation: The inclination angle of 30° is moderate, which can balance conveying efficiency and energy consumption, and has a wide range of applications.

Application scenarios: Common in mining, ports, grain processing and other industries, suitable for transporting coal, ore, grain and other materials.

The inclination angle is 45°:

Situation: The inclination angle of 45° is large, suitable for transporting some highly viscous materials, and helps prevent accumulation and blockage of materials.

Application scenarios: Common in cement, chemical, metallurgy and other industries, suitable for conveying powdery or granular materials.

The inclination angle is 75°:

Situation: The inclination angle of 75° is very steep, suitable for conveying some materials with small particles and easy to scatter.

Application scenarios: Used in fields such as ore beneficiation and construction waste treatment, it can effectively improve the conveying height and efficiency of materials.

The inclination angle is 90°:

Situation: The inclination angle of 90° represents vertical conveying, which is suitable for occasions where materials need to be conveyed from the bottom up.

Application scenarios: In some special occasions, such as garbage disposal, food processing and other fields, it is used for vertical or near-vertical material transportation.

| bandwidth B(mm) | 300 | 400 | 500 | 650 | 800 | |||||||||

| High sidewall(mm) | 40 | 60 | 60 | 80 | 80 | 120 | 120 | 160 | 120 | 160 | 200 | 240 | ||

| Partial conveying inclination conveying capacity Q3/h | 30° | 15 | 14 | 20 | 34 | 46 | 71 | 104 | 120 | 128 | 157 | 195 | 235 | |

| 45° | 11 | 10 | 14 | 26 | 35 | 57 | 83 | 97 | 102 | 127 | 157 | 195 | ||

| 60° | 8 | 7 | 10 | 18 | 25 | 40 | 58 | 69 | 72 | 90 | 112 | 142 | ||

| 90° | 4 | 4 | 5 | 10 | 13 | 21 | 31 | 37 | 38 | 48 | 60 | 76 | ||

| Dimensions | Head wheel center height(mm) | 350-100 | 1100-2000 | 1300-2000 | 1300-2000 | |||||||||

| Tail wheel center height(mm) | 335 | 330-490 | 600 | 600 | 600-800 | |||||||||

| Middle section with surface height(mm) | 450 | 500-700 | 760-800 | 800-850 | 800-1115 | |||||||||

| The width of the middle section of the foot(mm) | 480 | 580 | 870 | 1020 | 1220 | |||||||||

| bandwidth B(mm) | 1000 | 1200 | 1400 | |||||||||||

| High sidewall(mm) | 120 | 160 | 200 | 240 | 160 | 200 | 240 | 300 | 160 | 200 | 240 | 300 | 400 | |

| Partial conveying inclination conveying capacity Q3/h | 30° | 172 | 216 | 267 | 327 | 275 | 331 | 419 | 466 | 319 | 395 | 500 | 564 | 794 |

| 45° | 137 | 175 | 216 | 271 | 222 | 267 | 347 | 384 | 258 | 318 | 414 | 465 | 680 | |

| 60° | 96 | 124 | 153 | 197 | 158 | 190 | 253 | 178 | 184 | 226 | 302 | 337 | 524 | |

| 90° | 51 | 66 | 83 | 106 | 85 | 102 | 136 | 149 | 98 | 121 | 162 | 180 | 281 | |

| Dimensions | Head wheel center height(mm) | 1400-2000 | 1600-2000 | |||||||||||

| Tail wheel center height(mm) | 600-800 | 800-1000 | 800-1200 | |||||||||||

| Middle section with surface height(mm) | 800-1200 | 1050-1500 | 1050-1700 | |||||||||||

| The width of the middle section of the foot(mm) | 1440 | 1690 | 1890 | |||||||||||

(1) The conveying angle is large, and the maximum 90° material transportation can be realized, which can shorten the length of the conveyor and reduce the cost.

(2) It is not necessary to set up a conveyor corridor or a sealing cover, because the two conveyor belts can be clamped to realize airtight conveying of materials, and there will be no leakage of materials during the conveying process.

(3) Large conveying capacity and stable operation.

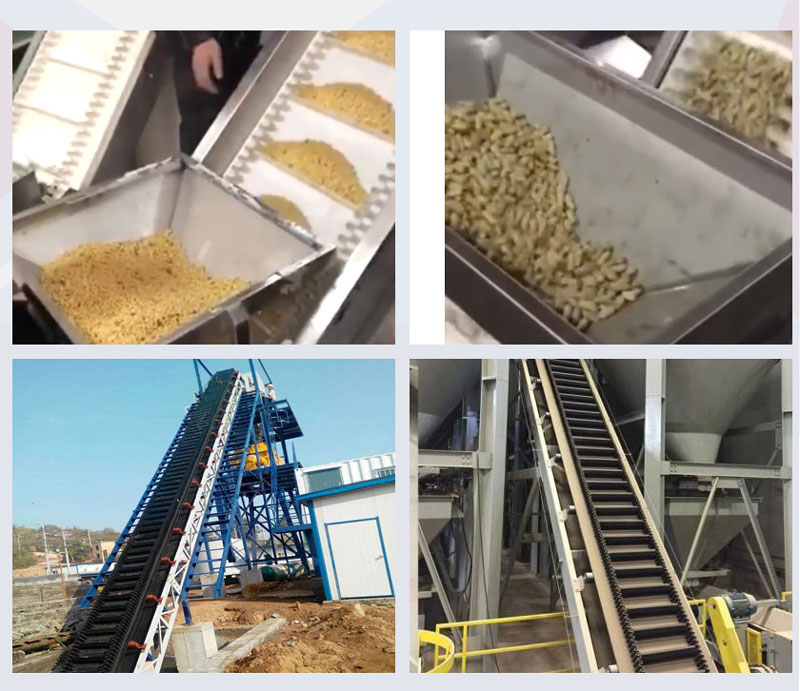

1. Flat belt conveyor and large inclination belt conveyor

The conveying inclination of the belt conveyor needs to be divided into two parts, one is a flat belt conveyor, and the other is a large inclination belt conveyor. The advantage of the flat belt conveyor is that it can carry out long-distance, large-capacity, and long-lasting transportation. The conveying inclination angle of the flat belt conveyor is generally 0-28°, and the maximum inclination angle is 28°. At a large inclination angle, the flat belt conveyor cannot effectively convey, because the material will flow by itself.

2. Patterned belt conveyor and deep trough (round tube) belt conveyor

The working principle of the patterned belt conveyor is the same as that of the ordinary belt conveyor. It mainly relies on the pattern on the surface of the patterned conveyor belt to increase the friction between the conveyor belt and the material, and increase the friction coefficient to realize the material transportation at a large inclination angle.

The deep trough belt conveyor uses idlers to support the conveyor belt in a U-shape or round tube shape. The working principle is the same as that of ordinary belt conveyors, and it can be used in common with ordinary belt conveyors.At this time, we need to use a large-inclination belt conveyor to transport. As the name suggests, a large-inclination belt conveyor is used in places where the inclination is relatively large. The conveying inclination range of the large-inclination belt conveyor is generally 30-90°.

The conveying of the large-inclination belt conveyor is actually mainly to lift the height, so the overall structure of the large-inclination belt conveyor is mainly composed of the upper and lower horizontal sections and the middle inclined section. The conveyor belt also uses a corrugated edge belt with skirts and partitions added to the base belt, which can effectively increase the friction between the conveyor belt and the material when conveying at a large angle, reduce the self-flow of the material, and effectively increase belt conveyor efficiency.The belt conveyors produced by our manufacturer have different conveying angles to meet your different needs. If you want to know more about the equipment, you can contact us.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.