It is commonly used in laboratories and research fields for particle size analysis, screening efficiency testing and particle distribution analysis of materials.

![]()

![]()

Price:$20.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Sieve diameter: 75mm, 100mm, 200mm, 300mm, 400mm, 500mm

Measuring range: 20µm-125mm

Feeding amount: 200g

Screen frame layers: 1-8 layers

Amplitude: 1-4mm Voltage: 220V

Power: 0.125KW Noise: ≤50dB

Dimensions: 360*300*736 Weight: 36 kg

Commitment: :Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Test shaker is a device used for screening and classifying granular materials, commonly used in laboratories and research fields. It can conduct particle size analysis, screening efficiency test and particle distribution analysis of materials.The primary function of a test shaker is to apply controlled mechanical vibrations or oscillations to the samples being tested. This agitation helps in mixing substances, dissolving solutes, extracting compounds, or conducting experiments that require controlled shaking or blending.

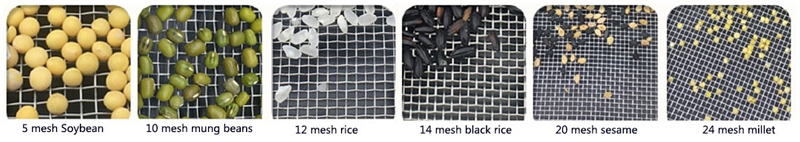

The common screen frame diameters of Test shaker are 75mm, 100mm, 200mm, 300mm, and 400mm. They are divided into metal wire braided mesh test sieves (screen size is 0.02mm-2.36mm) and metal perforated plate test sieves (screen size is 1mm- 125mm), electroforming test sieve (sieve size is 5μm-500μm). Samples of different sizes are separated through a pile of sieves of different sizes, which can be used individually or stacked in 7 layers.

Sieve Shaker

It is mainly used for laboratory sampling inspection and testing. It can accurately separate a kind of granular material into 2-8 particle segments at the same time. The test sieve machine can be customized to automatically shut down to ensure test repeatability.

Measuring range: 20µm-125mm

Feeding amount: 200g

Ultrasonic Sieve Shaker

It is an effective instrument to solve the problem of mesh clogging in the current laboratory when doing fine powder sample separation and screening. The mesh is not clogged and other characteristics, which solves the laboratory screening problems such as clogging of the mesh due to agglomeration, static electricity and strong adsorption.

Mesh Size: 635 mesh

Feed amount: ≤500

Electromagnetic Sieve Shaker

Electromagnetic sieve shaker uses electromagnetic vibrator as the vibration source, adopts high-frequency up and down vibration, and the vibration frequency can reach 3000 times per minute.

Mesh Size: 635 mesh

Feed amount: ≤500

Rotap Sieve Shaker

There are two screening methods: reciprocating and tapping vibration, which can discharge materials quickly and prevent materials from clogging. They are used for inspection of particle size composition of ordinary abrasives, classification of super-hard materials and detection of particle size.

Slap times: 156±3 times/min

Oscillation times: 290±6 times/min

| NO. | Type | Specifications |

| 1 | New standard sand sieve (φ300,7 pieces/set + bottom cover) | 9.50、4.75、2.36、1.18、600um、300um、150um |

| 2 | New standard stone screen (φ300 12 pieces/set + bottom cover) | 2.36、4.75、9.50、16.0、19.0、26.5、31.5、37.5、53.0、63.0、0.75、90.0mm |

| 3 | Road base aggregate screen (φ200, 300,11 / set + bottom cover) | 0.075、0.25、0.5、1、2、5、10、20、30、40、50mm |

| 4 | Drain the aggregate square sieve | 0.075、0.15、0.3、0.6、1.18、2.36、4.75、9.5、13.2、16、19、26.5、31.5、53mm |

| 5 | New standard square hole sieve (Φ200 ×50mm6 pieces/set) | Iron square hole:4.75、9.5、13.2、16、19、26.5、31.5、37.5、53mm Wire mesh square hole:0.075、0.15、0.3、0.6、1.18、2.36 |

| 6 | Blanking frame type sand screen (casting screen) φ200 (11 pieces/set) | 3.35、1.7、0.85、0.6、0.425、0.3、0.212、0.15、0.106、0.075、0.53mm |

| 7 | Pavement square hole aggregate screen | 80、60、50、40、30、25、20、10、5、2、1、0.5、0.2、0.075mm |

| 8 | Asphalt pavement aggregate screen (φ200, 300, 15 / set + bottom cover) | 0.075、0.15、0.3、0.6、1.18、2.36、4.75、9.5、13.2、16.0、19.0、26.5、31.5、37.5、53mm |

| 9 | Sand sieve Φ200 ×50(8 pieces/set) | Square hole copper mesh:2.5、1.25、0.63、0.315、0.16、0.08mm |

| 10 | Stone sieve Φ300 ×70mm (12 pieces/set) | 2.5、5、10、16、20、25、31.5、40、50、63、80、100mm |

| 11 | Lime screen (φ200 5 pieces/set + bottom cover) | 0.125、0.71、0.9、5、20mm |

| 12 | New standard pharmacopoeia sieve Φ 200×50mm (9 pieces/set) | 2、0.85、0.355、0.25、0.18、0.15、0.125、0.09、0、075mm |

Test shaker uses YZU vertical vibration motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating plate to vibrate, and then transmits it through the vibrating plate to the screen frame on the upper part of the vibrating plate. The material particles with the sieve aperture are sieved to the lower screen frame, so that only materials of the same size are left in each screen frame to achieve the separation of different particle sizes and determine the particle size composition of the material, so that the material in the screen frame It can be very effective for filtering, grading and sieving purposes.

Particle size analysis

Particle size analysis can be performed on granular materials to help determine the particle size distribution range of the materials. This is important for materials research, product development and quality control.

Screening efficiency

The screening efficiency of materials on different screens can be tested. By adjusting vibration parameters and screen size, the screening process can be optimized and screening efficiency improved.

Sieving consistency

A standardized screening process is provided to ensure the consistency and repeatability of screening results. This is important for comparative analysis and quality control.

Flexibility

It has replaceable screens and multi-layer screen settings, which can adapt to the screening needs of different particle size ranges. At the same time, some test screening machines also have adjustable vibration parameters to meet the screening requirements of different materials.

Laboratory scale

Typically smaller in size and lower power requirements, suitable for use in laboratory environments. They enable particle size analysis and screening operations in a relatively small space.

Save time and costs

It can quickly screen and classify granular materials, saving the time and labor costs of manual screening. At the same time, through the automated screening process, the possibility of human error is reduced.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Test shaker is widely used in different fields and industries, mainly used for particle size analysis and particle screening. Here are some common applications for test shakers:

Soil analysis: Used to determine the size distribution of particles in a soil sample to evaluate soil properties such as texture, permeability and water-holding capacity.

Construction Materials: Used to evaluate the particle size distribution of construction materials such as aggregate, sand and stone to ensure they meet specified standards and requirements.

Mining and Mineral Processing: Used for particle size analysis of materials such as ores, slag and mineral sand to determine their suitability and treatment effectiveness.

Chemical and pharmaceutical industry: used for screening and classifying granular materials to control the particle size distribution and quality of products.

Food and Beverages: Used to separate and screen raw materials, powders and granules to ensure product quality and consistency.

Environmental monitoring: used to analyze particulate matter in soil, water and air to assess its impact on the environment and health.

Scientific research: Test sieving machines are widely used in scientific research, including materials science, geology, biology and chemistry. They are used for particle size analysis and screening of granular materials to study their properties, behavior and interactions.

| Materials | Mesh size | Materials | Mesh size | Materials | Mesh size | Materials | Mesh size |

| sand | 2 mm | coal | 6 mm | coffee beans | 8 mm | steel ball | 12 mm |

| gravel | 5 mm | ore | 10 mm | iron powder | 150 micron | cellulose fiber | 40 mesh |

| flour | 100 mesh | sand | 1 mm | corn kernels | 4 mm | wheat bran | 800 micron |

| pulp | 200 mesh | salt | 500 micron | shattered glass | 3 mm | gravel | 20 mm |

| cement | 250 micron | medicinal powder | 300 mesh | plastic particles | 2.5 mm | raisin | 4.75 mm |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.