Trough screw conveyor is a common material conveying equipment and is widely used in various industries. According to different needs and application scenarios, common trough screw conveyor models include U-shaped, trumpet-shaped, tubular and rectangular.

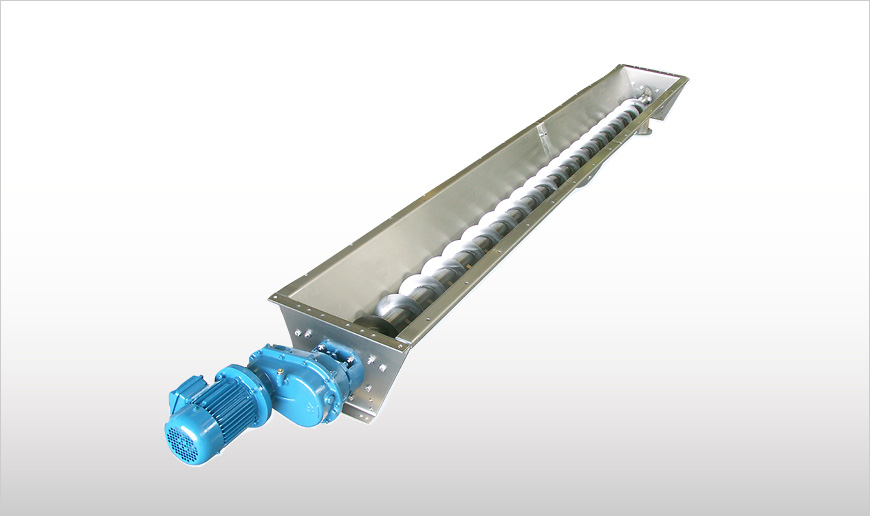

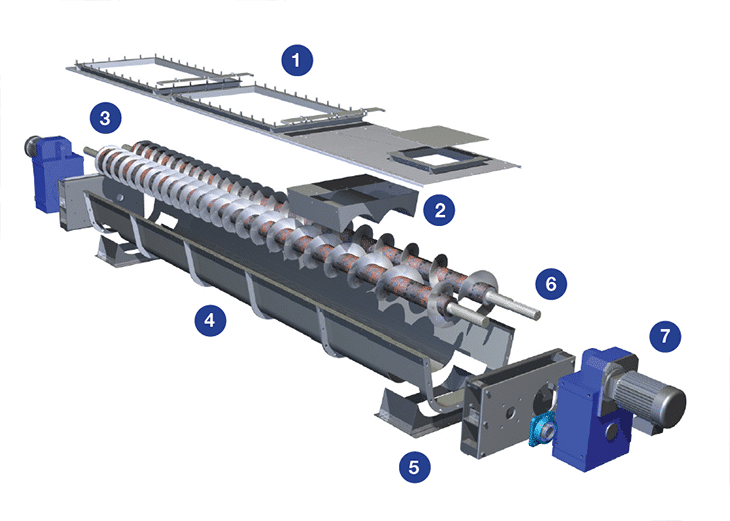

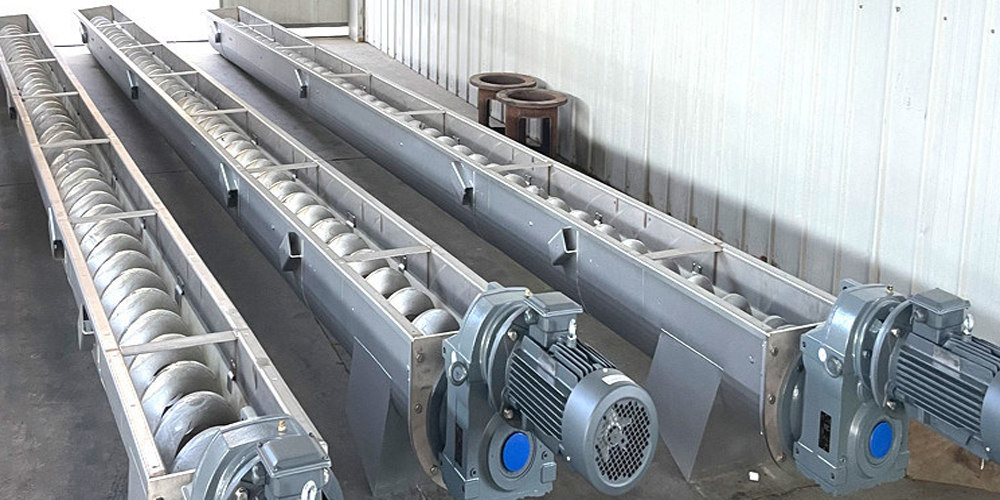

U-shaped trough screw conveyor is the most common model. Its conveyor trough presents a U-shaped cross-section and is suitable for conveying bulk materials. U-shaped trough screw conveyor has a simple structure and large conveying capacity. It is widely used in grain processing, chemical industry, building materials and other industries.

The groove design of the U-shaped trough screw conveyor enables the material to form a continuous spiral flow during the transportation process, ensuring smooth transportation of the material. It is suitable for conveying bulk materials such as granules, powders, and granule mixtures, such as grains, ores, coal, etc. U-shaped trough screw conveyors can be customized and designed according to the characteristics of materials and transportation requirements to meet the application needs of different industries.

The conveyor trough of the trumpet screw conveyor presents a trumpet-shaped cross-section, which is suitable for conveying sticky materials or materials that are easy to agglomerate. The trumpet-shaped screw conveyor can provide better sealing during the transportation process and prevent the spillage and accumulation of materials. It is commonly used in chemical industry, environmental protection and other fields.

The trumpet screw conveyor is suitable for conveying viscous materials, wet materials or materials that are easy to agglomerate, such as mud, fertilizers, powdered chemicals, etc. The design of the trumpet screw conveyor can reduce material clogging and adhesion and maintain the fluidity of materials.

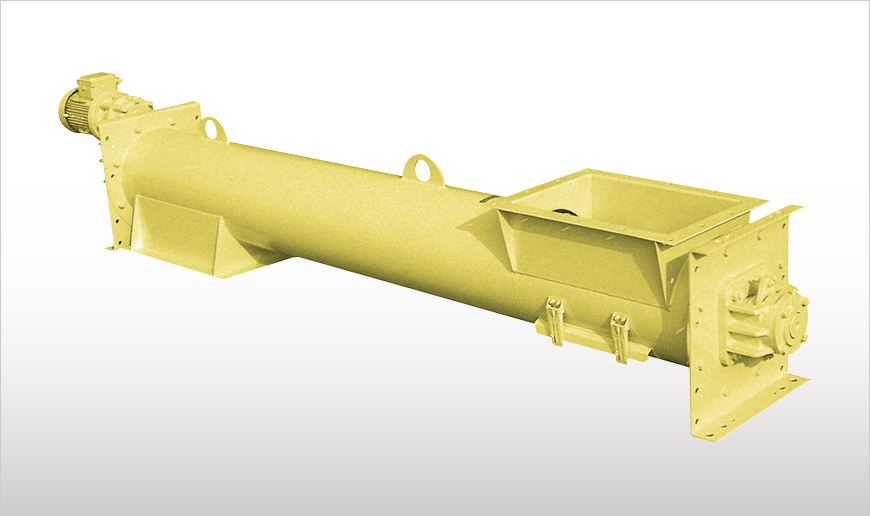

Tubular screw conveyors use pipes as conveying troughs and are suitable for long-distance transportation or scenarios where materials need to be protected from the external environment. Tubular screw conveyors usually consist of a spiral screw running inside a pipe to transport materials along the pipe.

Tubular screw conveyors can provide better sealing and dust-proof effects during the transportation process. It is commonly used in mining, cement, chemical industry, environmental protection and other industries, and is used to transport cement, ore, fertilizer, fly ash and other materials.

The trough of the rectangular screw conveyor presents a rectangular cross-section and is suitable for conveying bulk materials and sheet materials. Rectangular screw conveyors usually have a spiral screw running inside a rectangular trough to transport materials along the trough.

Rectangular screw conveyor has large conveying capacity and high conveying efficiency. It is commonly used in chemical industry, food processing, metallurgy and other industries, and is used to transport chemical raw materials, food raw materials, ore and other materials.

These are common trough screw conveyor models, each with its specific application areas and advantages. When selecting a model, factors such as the nature of the material, conveying distance, and conveying capacity need to be considered, and the selection should be based on actual needs. In addition, custom designs can be made to meet specific material handling needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.