Grain auger conveyors and grain conveyors are common grain transportation equipment. They have some differences in structure, working principle, scope of application, advantages and disadvantages, etc. The selection of suitable equipment should be based on factors such as specific transportation requirements, working environment, and budget. Consider it. Here is a detailed analysis of grain auger vs grain conveyor for grain auger conveyor:

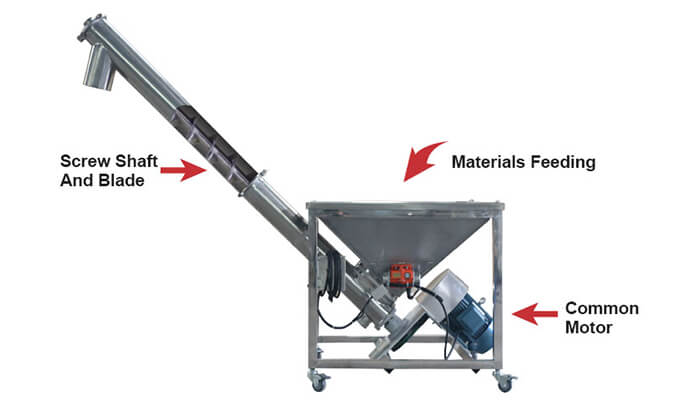

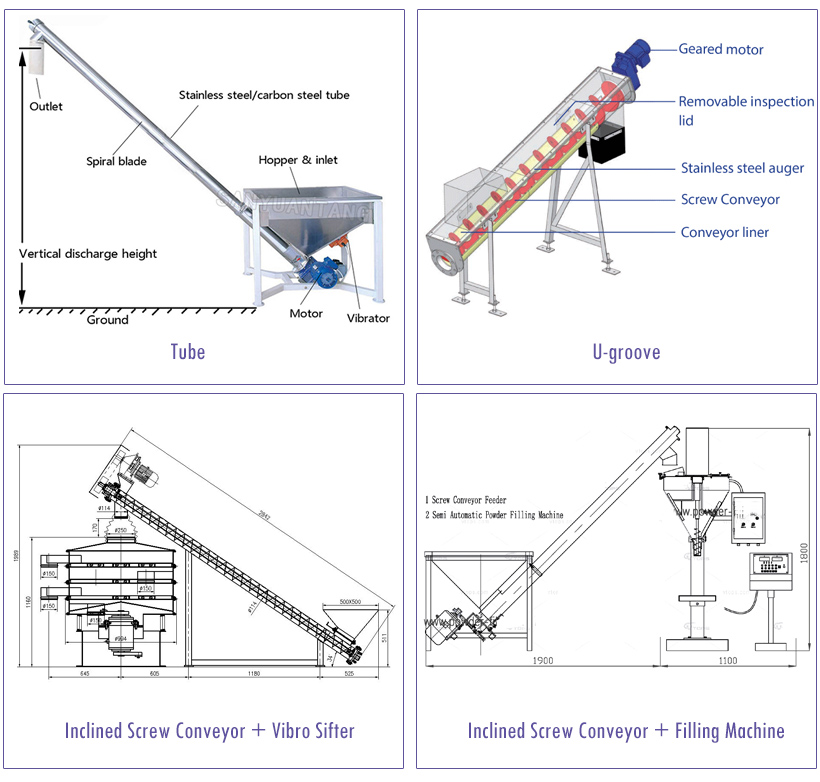

Grain Auger Conveyor: The screw conveyor consists of a spiral (screw) and a spiral groove (spiral tube). Spiral troughs are usually in the shape of a spiral, and the spiral pushes or transports the grain to its destination through rotation. Its structure is relatively simple, mainly composed of spiral groove, motor, reducer, etc.

Grain conveyor: Grain conveyor is mainly composed of conveyor belt, roller, support frame and other parts. Conveyor belts are usually made of rubber, polyurethane or metal materials and are driven by rollers to move continuously to transport grains from the starting point to the end point. Its structure is relatively complex, including conveyor belts, rollers, driving devices, support frames and other components.

Grain Auger Conveyor: The screw conveyor pushes or transports the grain along the track of the spiral groove through the rotation of the spiral. The thrust generated by the rotation of the spiral pushes the grain forward to complete the conveying process. The operating speed of the screw conveyor and the rotation direction of the screw can be adjusted according to actual needs.

Grain Conveyor: Grain conveyor transports grain from the starting point to the end point through the continuous movement of the conveyor belt. The conveyor belt is usually driven by a drive device that keeps it running, thereby transporting the grain along the direction of the conveyor belt. The running speed and direction of the conveyor belt can be adjusted according to needs.

Grain auger conveyor: Grain screw conveyor is suitable for grain transportation with shorter distance and smaller flow rate. It is often used in grain storage systems, unloading, feeding, and transfer during grain processing. Due to its simple structure and small footprint, it is suitable for places with limited space or where flexible layout is required.

Grain conveyor: Grain conveyor is suitable for conveying grain over longer distances and with large flow. It is often used for long-distance transportation in grain warehousing and logistics transportation systems, such as transporting grain from warehouses to shipping ports, processing plants or other destinations. Because the length of its conveyor belt is adjustable, it is suitable for longer-distance conveying needs.

The advantages of grain auger conveyors include simple structure, small space occupation, and suitability for limited space or places requiring flexible layout. However, the disadvantage is that the conveying capacity is relatively low and suitable for grain conveying over short distances and small flow rates.

The advantages of grain conveyors include strong conveying capacity and suitable for conveying grains over long distances and large flows. However, the disadvantages are that the structure is relatively complex and it takes up a large space.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.