The main purpose of concrete vibrating table is to improve the quality and construction efficiency of concrete.

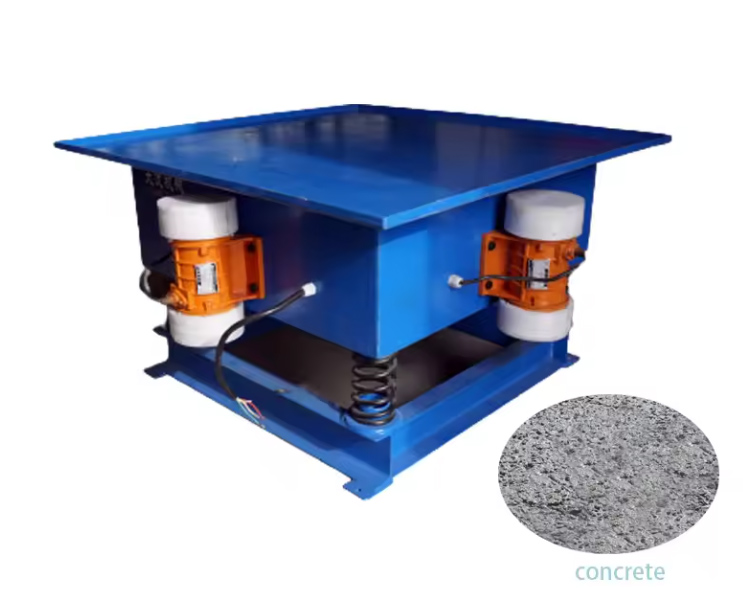

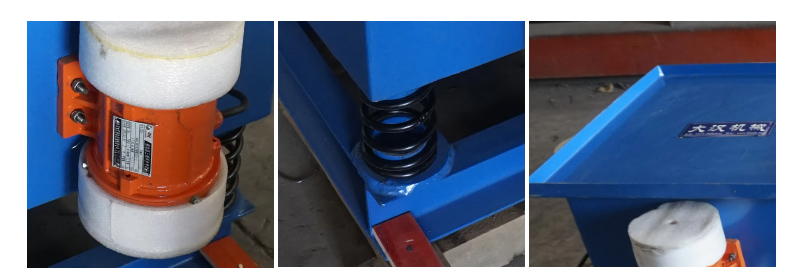

The application of concrete vibrating table in concrete construction is a wide and important topic. Vibrating platform, also known as vibrating table or vibration platform, is a device that improves the quality and performance of concrete through vibration. It is mainly used to remove bubbles in concrete, improve the compactness and strength of concrete, and thus ensure the stability and durability of concrete structure.

Concrete vibrating table, also known as concrete vibrator, is a device that improves the quality and performance of concrete by generating high-frequency vibration. Its main functions include:

Improve the compactness of concrete: Through the action of vibration, the particles in the concrete can be rearranged and the gaps can be filled, thereby improving the compactness of the concrete and enhancing the strength and durability of the concrete. Eliminate bubbles: Vibration can help eliminate bubbles in concrete, reduce defects and cracks in concrete, and improve the impermeability and durability of concrete.

Improve the construction environment: Compared with traditional concrete construction methods, the use of vibrating table can greatly shorten the construction period, while reducing noise and dust pollution during construction, and improving the construction environment.

In addition, concrete vibration tables are also widely used in various types of concrete structure construction, such as bridges, buildings, roads, tunnels, etc. Whether it is a large-scale engineering project or a small civil building, you can see the figure of the vibration table. Therefore, the concrete vibration table is one of the indispensable and important equipment in concrete construction.

In addition to its application in construction, the concrete vibration table also conducts relevant vibration tests on samples in laboratories and production lines, such as environmental acceptance tests, quality identification tests, reliability identification tests, and durability tests. By simulating the vibration environment that the product is subjected to during manufacturing, assembly, transportation and use, the vibration resistance, reliability and integrity of its structure can be evaluated.

In actual concrete construction, the application of the vibration platform also needs to be selected and configured in combination with specific engineering requirements. Different types of vibration platforms have different characteristics and scope of application, which need to be comprehensively considered according to factors such as the scale, structural form, and construction conditions of the project. For example, for some large-scale engineering projects, you may need to choose a vibration platform with higher power and better vibration effect; while for some small civil buildings, you can choose a vibration platform with lower power and easier operation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.