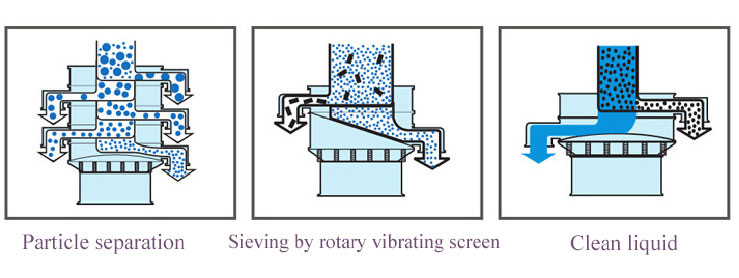

Screening equipment is a common industrial mechanical equipment whose main function is to separate and classify granular, powdery or liquid materials. In manufacturing, many raw materials and products need to be processed by screening equipment to ensure their quality and market competitiveness. The specific function of screening equipment and its application in industry will be introduced in detail below.

Screening equipment can quickly and efficiently remove impurities from granular materials and separate them out. In different industries, the raw material itself or other substances are mixed in it, which will affect the quality of the product. For example, in the pharmaceutical industry, it is required that the medicinal materials are not allowed to have any foreign matter, otherwise it will affect the quality of the pharmaceuticals. The use of screening equipment for fine screening and deep separation can remove impurities and broken materials contained in granular materials, ensuring product quality and safety.

Different industrial applications require different particle sizes. Screening equipment can classify materials, and this classification must use different types of screens to achieve different screening effects. For example, in the feed industry, since different animals require feed with different particle sizes, the feed must be sieved to achieve the best feed effect.

Many materials contain too much water, which needs to be properly removed in order to ensure the texture and performance of the product. Screening equipment can be separated and vibrated to promote the separation of water. For example, in the process of manufacturing fermentation solution, the screening equipment can extract the water in the solution to separate the water from the fermentation material, thereby improving the fermentation effect.

Screening equipment can process raw materials quickly and efficiently, separate out impurities, and carry out precise classification, which helps to improve production efficiency. If there is no screening equipment, manual screening is required, which is time-consuming and labor-intensive, resulting in a waste of human resources. The use of screening equipment can efficiently increase production, reduce labor costs, and gain an advantage in market competition.

In short, screening equipment is an indispensable part of modern production and manufacturing processes. Through screening, it is possible to remove impurities in the material, classify the particle size, remove moisture and increase production, so as to ensure production efficiency and quality, reduce costs and improve market competitiveness.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.