Used to ensure material uniformity, remove impurities and improve product quality.

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Function: Screening, separation, sorting, sieving, grading

Diamater Size: 400~2000m

Screen Mesh: 2-500 Mesh

Capacity: 100Kg-10Tons/hour

Layer(s): 1-5 Layers

Noise Level: less than 80dB

Material: Carbon Steel, Stainless Steel 304/316L

Application: There are a variety of applications in various industries, including pharmaceuticals, food processing, chemical engineering, mining and agriculture.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

A sifter machine, also known as a screening machine or sieve machine, is a mechanical device used to separate, classify, and remove impurities from particles or materials based on their size or shape. It employs a vibrating or rotating screen, typically made of mesh or perforated plates, to separate larger particles from smaller ones.

Sifter machines are widely used in various industries such as food processing, pharmaceuticals, chemicals, mining, and agriculture. They play a crucial role in quality control, process optimization, and ensuring product consistency.

Sifter machines are versatile equipment used across various industries for a wide range of applications. Some common uses of sifter machines include:

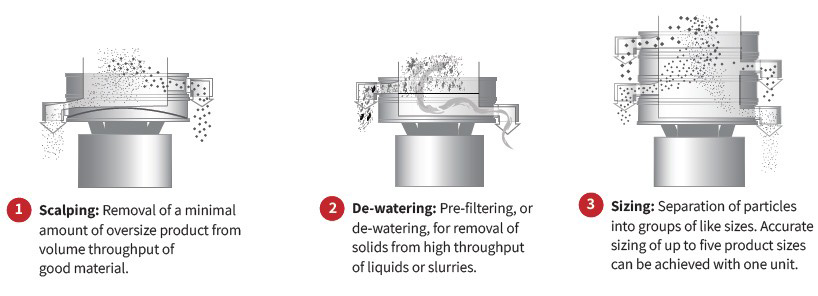

1.Particle Size Classification: Sifter machines are often employed to separate particles based on size. This is crucial in industries such as pharmaceuticals, food processing, and mining where precise particle size distribution is required.

2.De-Dusting: In industries like agriculture and food processing, sifter machines are used to remove dust, fines, and other impurities from materials, improving product quality and safety.

3.Scalping: Sifter machines are utilized for scalping applications to remove large contaminants or foreign materials from raw materials before further processing.

4.Separation of Agglomerates: Sifter machines are effective in breaking down agglomerates or clumps of material, ensuring a more uniform product.

5.Safety Screening: Sifter machines are employed for safety screening to remove any foreign objects or contaminants from products before packaging or distribution.

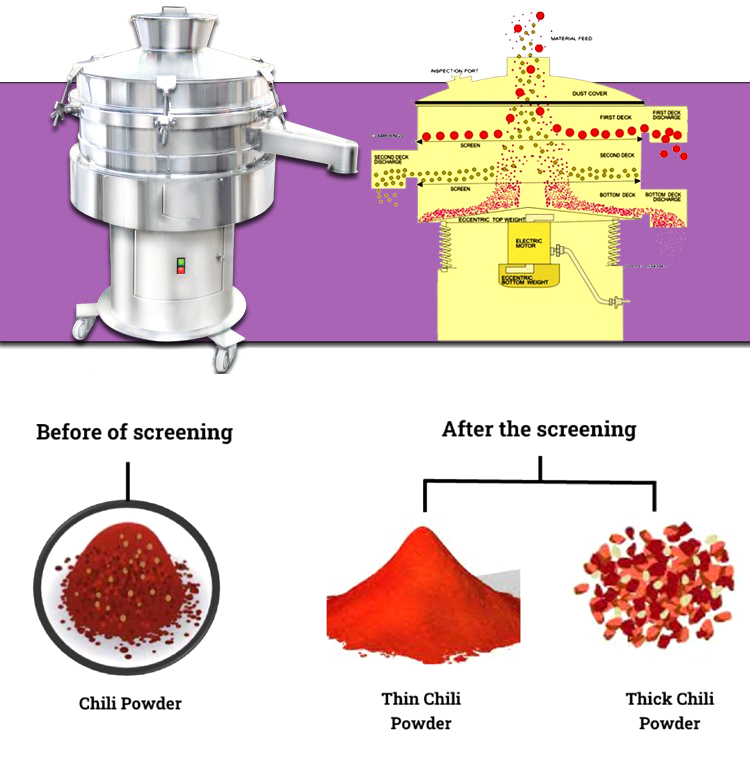

Material Feeding: The material to be screened is fed onto the sifter machine, typically at the top or one end of the machine. It can be gravity-fed or fed using a conveyor or feeder mechanism. Vibratory or Rotating Motion: The sifter machine imparts a vibratory or rotating motion to the screen, causing the material to move along the screen surface. This motion helps to distribute the material evenly and encourages smaller particles to pass through the screen openings.

Separation and Classification: As the material moves along the screen surface, the smaller particles that can fit through the screen openings pass through and are collected as the desired product or fraction. The larger particles are retained on the screen surface and are usually discharged separately as oversize or rejected material.

Discharge and Collection: The separated particles are collected through outlets or chutes located beneath the screen. Depending on the application, the machine may have multiple outlets to collect different size fractions or categories.

Efficient Particle Separation

Sifter machines efficiently separate particles based on their size, ensuring uniform particle sizes and consistent product quality. This is important for industries that require precise size control, such as pharmaceuticals, food processing, and mining.

Improved Product Quality

By removing oversized particles, foreign objects, or impurities, sifter machines help improve product quality and purity. This is particularly crucial in industries like food processing, where product safety and hygiene are paramount.

Increased Production Efficiency

Sifter machines enable high-speed and continuous screening operations, increasing production efficiency and throughput. They can handle large volumes of material, reducing processing time and improving overall productivity.

Versatility and Adaptability

Sifter machines are available in various configurations and sizes, allowing them to adapt to different material characteristics and processing requirements. They can be customized with different screen types, mesh sizes, and deck arrangements to suit specific applications.

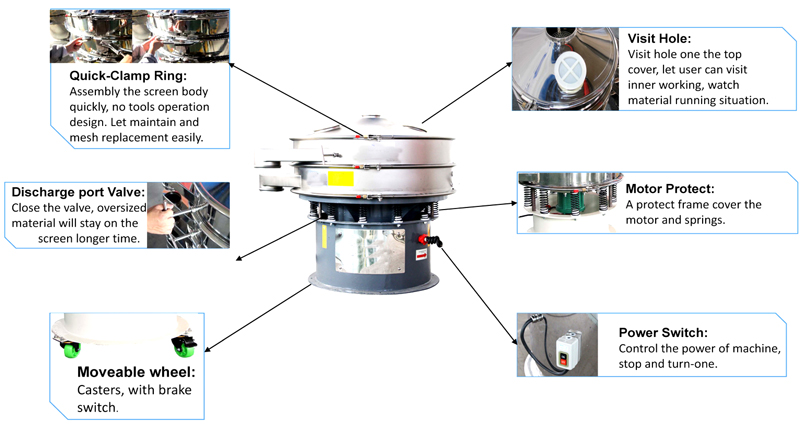

Easy Maintenance and Cleaning

Many sifter machines are designed for easy maintenance and cleaning. Quick-change screen options, accessible components, and user-friendly designs simplify maintenance tasks, reducing downtime and ensuring smooth operation.

Cost Savings

By automating the particle separation process, sifter machines reduce the need for manual labor, leading to cost savings and improved operational efficiency. They minimize the risk of human error and ensure consistent screening results.

The above parameters are commonly used models, the data are for reference only, we can also customize according to your needs.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Sifter machine structure design and function can be customized according to different material characteristics and process requirements.

1. Add-edge type: The heightened protection design of the feed inlet can increase the feed volume, prevent material splashing, and facilitate the observation of the screen. It is suitable for the chemical industry, food industry, papermaking industry, metallurgical industry, pharmaceutical industry, environmental protection and other fields.

2. Gate type: The gate design controls the retention and screening time of the material on the screen to ensure the processing accuracy of difficult-to-screen materials (such as sticky and fine materials) and increase the processing volume.

3. Anti-corrosion type: The part in contact with the material is made of polypropylene (PP plastic), which is suitable for screening materials that are corrosive to metals such as carbon steel and stainless steel.

4. Explosion-proof type: The motor adopts a special design, and the whole machine has better sealing, which is suitable for the screening requirements of special industries (such as powders, materials that are prone to static electricity, etc.).

5. Add hopper: It can evenly disperse the material on the screen surface, avoid local overload, extend the service life of the screen, and uniform feeding helps to improve screening efficiency.

6. Add scraper: During the screening process, fine particles and sticky substances in the material are easy to clog the screen, affecting the screening efficiency. Adding a scraper device can effectively solve this problem.

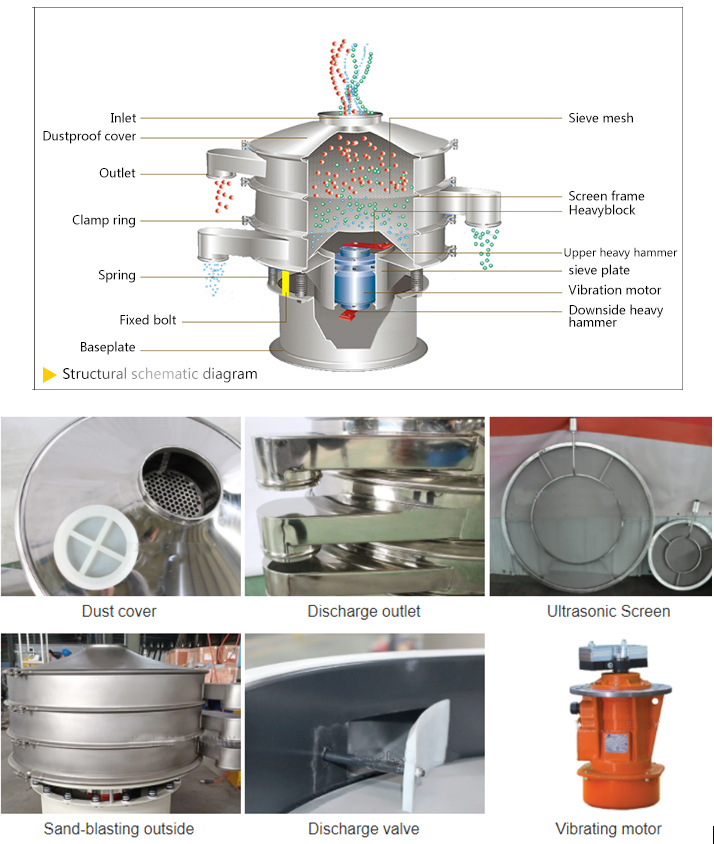

A sifter machine, also known as a screening machine or sieve, typically consists of the following components:

1. Frame: The main structural support of the machine, providing stability and rigidity.Can be made of various materials like steel, aluminum, or cast iron, depending on the machine's size and application.

2. Vibrator: A motor is the main component of a sifter machine which powers the whole machine and allows the screens to vibrate. Electrical power is given to these motors which are further converted into energy or mechanical form. Once the moment gets smooth through proper rpm of motor, the material is feed in the hopper lid. Depending on the production capacity and volume, selection of motor rating holds significant importance.

3. Screen or Mesh: The perforated surface through which particles pass, separating them based on size.The mesh size can be varied to achieve different levels of particle separation.

Can be made of various materials like wire mesh, woven fabric, or perforated sheet metal.

4. Screen Deck: The frame that supports the screen mesh.Can be fixed or adjustable to accommodate different screen sizes.

Optional Components:

Cleaning Mechanism: Some sifter machines have built-in mechanisms to clean the screen and prevent clogging, such as bouncing balls, ultrasonic cleaning devices or brushes. Dust Collection System: For applications where dust is a concern, a dust collection system can be integrated into the machine.

Sifter machines, also known as screening machines or sieve machines, have a wide range of applications across various industries. Here are some common applications of sifter machines:

Food Processing: Sifter machines are extensively used in the food industry for processes such as ingredient screening, flour milling, starch processing, sugar production, spice processing, and grading of fruits and vegetables. They help remove impurities, ensure consistent particle sizes, and improve product quality and safety.

Pharmaceuticals and Chemicals: Sifter machines play a crucial role in the pharmaceutical and chemical industries. They are used for sieving powders, granules, and solid materials, such as active pharmaceutical ingredients (APIs), excipients, catalysts, and chemical powders. Sifter machines ensure the quality and uniformity of these materials, meeting strict regulatory standards.

Mining and Minerals: Sifter machines are utilized in mining and mineral processing operations to separate and classify various minerals, ores, and aggregates. They help remove oversized particles, improve particle size distribution, and enhance the efficiency of downstream processes like grinding, flotation, and mineral concentration.

Recycling and Waste Management: Sifter machines are used in recycling and waste management facilities to separate different types of materials, such as plastics, paper, metals, and glass. They help segregate recyclable materials from waste streams, facilitating the recycling process and reducing landfill waste.

Construction and Aggregates: Sifter machines are employed in the construction industry to classify and separate aggregates like sand, gravel, and crushed stone. They help ensure the desired particle size distribution for concrete production, road construction, and other applications.

Agriculture and Farming: Sifter machines find application in agriculture and farming operations. They are used for seed cleaning, grain sorting, soil screening, compost processing, and separation of agricultural products like nuts, fruits, and vegetables. Sifter machines help improve product quality, remove impurities, and optimize yields.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.