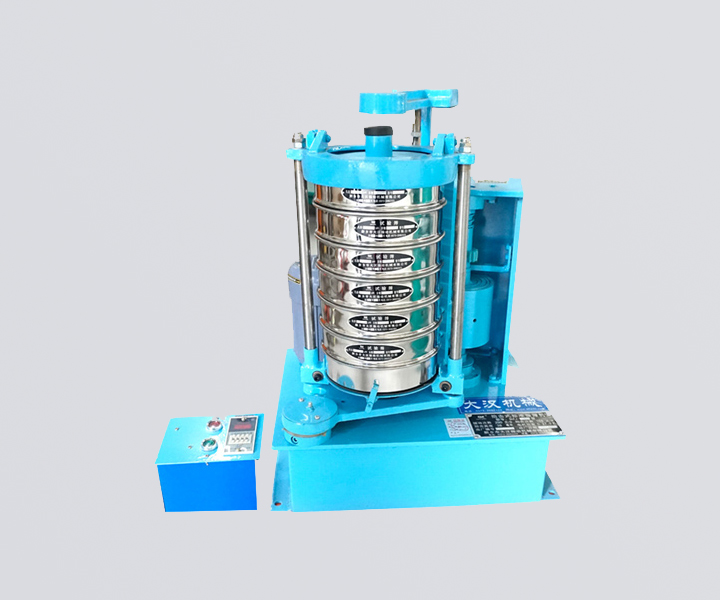

Lab sieve machine

Lab sieve machine Lab sieving machine

Lab sieving machine Lab sieve shaker

Lab sieve shaker Brass lab sieve machine

Brass lab sieve machine Fine stainless steel lab sieve machine

Fine stainless steel lab sieve machine

Dry and wet screening of large batches up to 25 kg

![]()

![]()

Price:$200.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

Diameter:100mm/200mm/300mm/400mm

Layer(s):1-8 layers

Screen material:SS 304 Woven Wire Mesh

Mesh size:0.038-3mm

Feeding Capacity(Once):<200 g/ml

Voltage:220V

Weight:45kg

Application: It is used for grading and filtration of various materials in chemical, food and other industries in laboratories and laboratories, such as chemical powders, food additives, etc.

Commitment:

Lab sieve machine is mainly used in the laboratory to classify and analyze powders, bulk particles and suspensions, and separate samples of different sizes by stacking sieves with different meshes. Up to 8 layers of sieves (including receiving trays) can be stacked. When feeding 1-1.5kg each time, a granular material can be precisely separated into 2-7 particle segments at the same time.

Lab sieve machine usually has diameters of 100mm, 200mm, 300mm, etc. It can also be customized into 75mm and 400mm according to customer requirements, with a built-in timer of 0-99 minutes, and the same amount of screening time can be set according to needs to ensure sample analysis data. The consistency of the inspection will reduce the inspection error to a very low level, so that the product quality data is accurate.

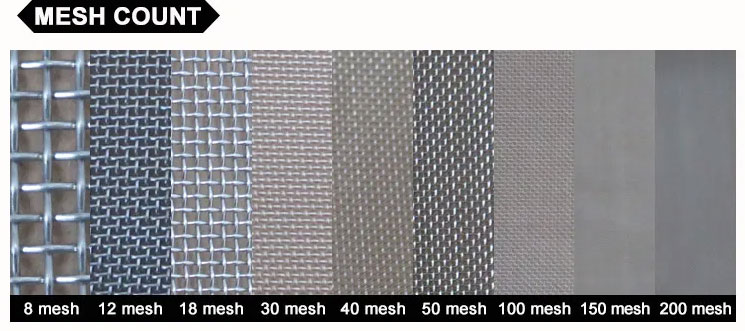

Measuring range: 8 mesh - 400 mesh

Application:Used in laboratories, universities and other scientific research institutions for particle size detection, particle size analysis, and debris content analysis

Measuring range: 20 microns

Application: Suitable for fine powder with high static electricity, strong absorption force, high density and light specific gravity

Measuring range: 5 μm-63 mm

Application: Used in the production and grading process of diamond micropowder and superhard materials industry for repeated use with high strength and high frequency

1. Metal wire woven mesh lab sieve machine: It is widely used, the shape of the mesh is square hole, the price is cheap, the application range is wide, and it is light and durable.

Diameter: 200mm, 75mm, 300mm

Sieve hole size: 0.02mm~2.36mm

Executive standard: GB/T6003.1-1997 (equivalent to ISO3310.1)

2. Metal perforated plate lab sieve machine: It is a test screen that is directly punched into a fixed shape and size of sieve on steel plate or other sieve body materials. This type of screen is mostly square or round, safe and firm , suitable for materials with relatively high density, large impact on the screen surface and irregular shapes.

Diameter: 200mm, 300mm

Sieve hole size: 1mm~125mm

Executive standard: GB/T6003.2-1997 (equivalent to ISO3310.2)

3. Electroforming lab sieve machine: Produced by electrochemical methods, the precision is the highest (up to one micron), but the cost is high, and it will only be used in some high-precision laboratories.

Diameter: 75mm, 200mm

Mesh size: 5um~500um

Executive standard: GB/T6003.3-1999 (equivalent to ISO3310.3)

| Model | DH-75 | DH-100 | DH-200 | DH-300 |

| Nominal diameter (mm) |

Φ75 | Φ100 | Φ200 | Φ300 |

| Screening size (mm) |

0.038-3 | |||

| Noise (dB) |

≤50 | |||

| Feeding amount (one-time) (g) |

≤200 | |||

| Amplitude (mm) |

≤5 | |||

| Voltage (V) |

220V(Or as required) | |||

| Power (Kw) |

0.125 | |||

| Dimensions (mm) |

360*300*736 | |||

| Support customized production(Click here to get accurate quotation) | ||||

The above are common diameters, there are also test sieves of 100, 150, 250, 450, 500, 600mm available to separate the particles by passing them through a series of sieves with different mesh sizes to achieve complete separation, according to Depending on the equipment, there are options for sieving powder, solid and liquid samples, and the choice of equipment will depend on the type of laboratory and the samples being processed.

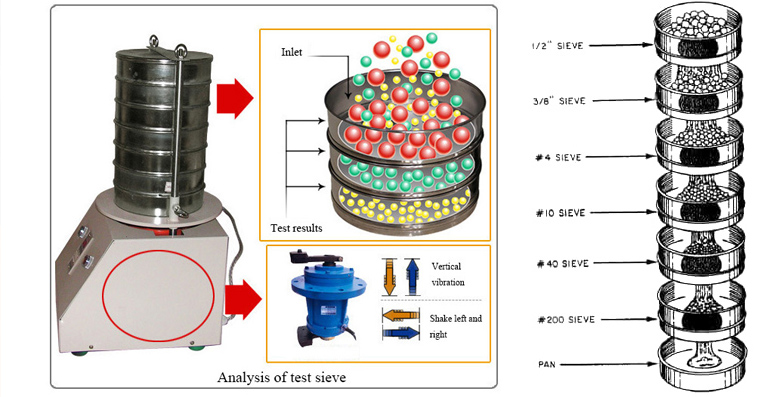

Lab sieve machine uses YZU vertical vibrating motor as the vibration source of the whole machine, drives the upper vibrating plate to vibrate through the vibrating motor, and then transmits it to the screen frame on the upper part of the vibrating plate through the vibrating plate, and then uses the screen frame that needs to detect the mesh number to vibrate The material particles smaller than the pore size of the screen are screened to the lower screen frame, so that only the same particle size materials are left in each layer of the screen frame, so as to achieve the separation of different particle sizes and determine the particle size composition of this material, so that the particles in the screen frame materials can be very effective for filtering, grading and screening purposes.

durable

The screen frame is made of SUS304 stainless steel by stretching and polishing, with a wall thickness of 0.6 mm. The screen can be electroplated, and chemical processing can make the screen surface smooth and wear-resistant. At the same time, the warp and weft nodes are fixed together, and the mesh will not be deformed after long-term use.

Multi-layer filtering

Samples of different sizes are separated by a stack of sieves of different sizes, which can be used individually or stacked in 8 layers (including feeding trays), which can divide a product into 7 different particle segments.

Precise mesh

The screen used in it is produced in strict accordance with the GB6003.1-1997 standard and selected by a tool microscope to ensure its precision.

Controllable detection time

The equipment is equipped with a timer and can be shut down regularly to ensure the consistency of each production or test.

Lab sieve machine, separates samples of different sizes through a stack of sieves of different sizes, which can be used individually or in stacks of 8 layers. It can quickly and effectively measure the size of solid particles from 125mm to 20μm. It is mainly used in laboratories for powder, The classification and particle size determination of bulk particles and suspensions are also commonly used in fields such as particle size composition inspection of ordinary abrasives and production and classification of superhard materials.

Pearl powder screening

filter slurry

Screen: The screen is the high-tech part of the lab sieve machine. The most commonly used mesh type is stainless steel woven wire mesh. Opening sizes are 5 inches (125 mm) to 635 mesh (20 microns).

Screen Frame: Frames are circular metal rings that hold the mesh in place. Standard frame sizes in the U.S. are 3 inches, 8 inches, and 12 inches. Internationally, 100mm, 200mm and 300mm are standard sizes. The screen frame can be made of stainless steel or brass.

Skirt: The main function of the skirt is to allow the sieves to be stacked without tipping over.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 70# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

To purchase a lab sieve machine, you need to provide the necessary information:

It is precisely because of the consideration of the accuracy of the experimental results that Dahan Machinery recommends that major laboratories or school scientific research institutions must provide detailed application information when consulting and purchasing lab sieve, so that vibrating screen manufacturers can customize accurate standard labs according to national standards. For sieve machine, the specific data that needs to be provided are as follows:

1. What standards need to be provided. (Example: I need a standard sieve that meets the national standard GBT6003-1997)

2. Provide mesh size and wire diameter.

3. What materials are tested.

4. Square hole sieve or round hole sieve.

Precautions for ordering laboratory standard vibrating sieve machine (national standard test sieve)

1. (Please note) The standard sieve above 120# in the national standard is braided with copper, if you need stainless steel, please explain.

2. The lab sieve machine produced by our factory is a standard sieve that conforms to the national standard GBT6003-1997 or the international standard ISO3310-1: 1990. The sieve frame is made of stainless steel (SUS304), with a diameter of 200mm, a height of 50mm, a wall thickness of 0.6mm, and 120# The above adopts copper mesh, and the following adopts stainless steel mesh. If you have special requirements, please ask.

| Product | Mesh Size | Product | Mesh Size | Product | Mesh Size |

| Soybean | 5 mesh | yellow worm powder | 12 mesh | Rice | 12 mesh |

| Sesame | 20 mesh | corn flour | 30 mesh | Pharmaceutical powder | 50 mesh |

| Flour | 50 mesh | Notoginseng powder | 80 mesh | Seasoning | 60 mesh |

| Pearl powder | 150 mesh | cereals | 0.025mm-3mm | Iron powder | 270 mesh |

| Plastic particles | 5mm | resin | 2mm | Graphite powder | 500 mesh |

| Aggregate | 75μm | Aluminum oxide | 100μm | Chemical powder | 150μm |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.