A sieving machine is a device used to separate different particle sizes and is often used in the production process of powdery or granular substances.

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Screen frame: 1-5 layers (3 layers is best)

Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

Motor power: 0.25Kw to 2.2Kw or customized

Power supply: 220/240/380/415/450V can be used. 50 or 60HZ.

Application: Suitable for dry or wet applications such as silica, ceramics, powder coatings, tapioca starch, coffee beans, copper powder, silver powder, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Sieve machine is suitable for screening and filtering granular, powder, mucus and other materials. It can be used at the same time for 1-5 layers according to the different needs of customers. It is complete in various models such as carbon steel, 304 stainless steel and plastic materials. It is also suitable for the needs of special industries. It can be designed as gate type rotary vibrating screen, edge-added rotary vibrating screen and other models.

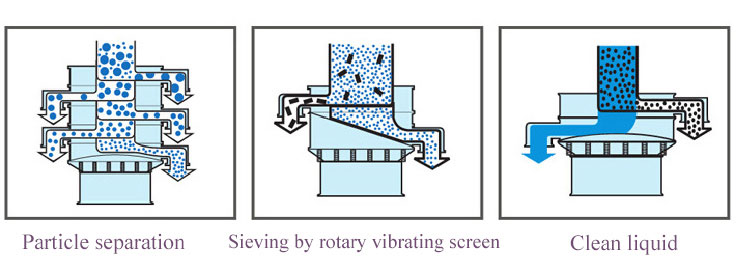

1.Classification: Divide the powder and particles into particle segments of different sizes, which can be equipped with 1-5 layers of screens, which can continuously sort 2-6 kinds of particles.

2.Impurity removal: In the process of high-flow processing, it can quickly remove large or small particles with a low percentage of materials.

3.Filtration: Quickly remove insoluble substances in various types of slurry, and continuously discharge slag.

The Sieve machine uses a vertical motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights, which convert the rotation of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the screen surface.

1. It can meet the requirements of various powder and particle screening requirements and liquid filtration requirements. The screening is as fine as 500 mesh or 0.028mm, and liquid materials can be filtered to 5 microns.

2. Bounce to remove the net device is installed under the screen of each layer, by constantly hitting the screen, the material can be screened smoothly and effectively avoid the problem of material blocking the net.

3. Impurities and coarse materials are automatically discharged, continuous operation is possible, and the output can reach up to 5 tons/hour

4. 1-5 layers of multi-layer screening can obtain 2-6 kinds of finished products with different specifications.

5. Fully sealed structure, no powder overflow, no liquid overflow.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Chemical industry: resins, coatings, industrial medicines, pigments, paints, Chinese medicine powder, etc.

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

Metals, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy carbonic acid Calcium, quartz sand, etc.

Pollution treatment: waste oil, wastewater, dyeing and finishing wastewater, additives, activated carbon, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.