Particle size testing is a procedure used to determine the size distribution of particles in a sample. It involves measuring and analyzing the dimensions of individual particles or aggregations of particles within a given material. The particle size of a substance is typically described in terms of its diameter or equivalent spherical diameter.

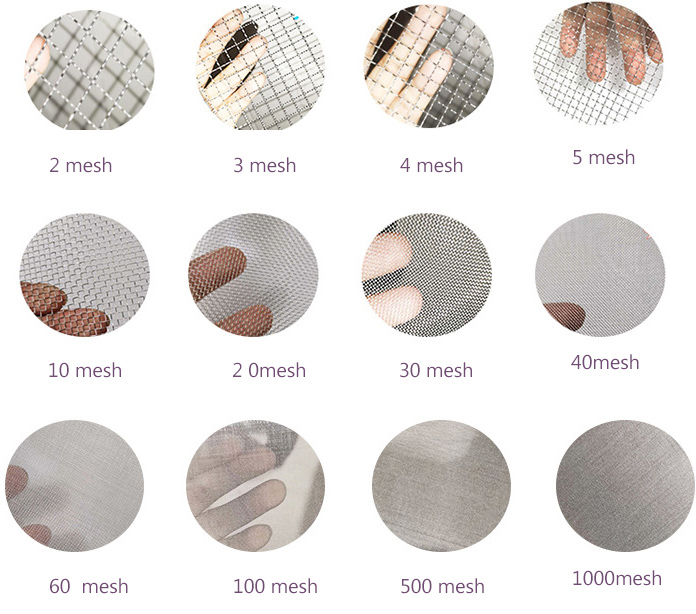

Particle size test is divided into three types, each with different characteristics and application scope: metal wire braided mesh (widely used, with mesh openings ranging from 2.36 mm to 0.02 mm, only square hole mesh), punched plate screen (main application For large meshes, there are round holes and square holes with meshes ranging from 0.2 to several hundred millimeters), electroforming screens (mainly used in high-precision situations, and each mesh can be within the average error range) .

Pharmaceuticals: Particle size analysis is critical in drug formulation, ensuring uniformity and consistency in dosage forms like tablets and capsules.

Food Industry: In food processing, particle size testing is used to control the texture, mouthfeel, and appearance of food products.

Paints and Coatings: Particle size distribution affects the properties of paints and coatings, such as gloss, color, and durability.

Environmental Analysis: Particle size testing is used in environmental monitoring to analyze pollutants, sediments, and airborne particles.

Cosmetics: In the cosmetics industry, particle size analysis helps in developing products with desired characteristics like smoothness and spreadability.

As particle size plays an integral role in the performance of the final product, it is essential that you are implementing particle analysis in your quality control protocol. Not knowing the size of your material's individual particles can cause major issues within your production line, costing you thousands, if not millions of dollars in potential revenue.

For example, in the fracking industry, if you are working with a mixture of particle sizes that are too variant, an uneven distribution of vacuum pressure can be created. In turn, the fracture in which the oil is being drawn from may shift, closing the wellbore and hindering the production of oil.

The pharmaceutical industry, on the other hand, relies on particle size as it controls the rate in which medicine dissolves and disperses throughout your body. Failure to know and control the particle size of any given medicine can lead to costly lawsuits and, more importantly, cause harm to the patient taking the medication.

In conclusion, particle size testing plays a vital role in various industries by providing valuable insights into the physical properties of materials, enabling quality control, process optimization, and product development.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.