Aluminum powder, commonly known as "silver powder", is a silver metallic pigment. It is made by adding a small amount of lubricant to pure aluminum foil, crushing it into a scaly powder, and then polishing it. Aluminum powder can be used to identify fingerprints and can also be used as fireworks. Aluminum powder is a large category of metallic pigments due to its wide application, large demand, and variety. Aluminum powder materials need to use vibrating screen equipment in the production line to ensure the fineness of the materials, so which vibrating screen is generally suitable for aluminum powder? Normally, 100 mesh and 200 mesh are the common sieve meshes, and vibro sifter is usually used in many places.

The vibro sifter is suitable for separating powder with a sieving mesh from 0 to 400 meshes. It is very suitable for sieving aluminum powder and can effectively solve the problem of blocking fine materials in the screening process. Adopting "strong" new power vibration exciter, the three-dimensional power is more prominent, and the scope of application is wider. Dahan's vibro sifter series products are also equipped with a special screen cleaning device to reduce the blocking rate to a low rate, and the screen passing rate and processing accuracy can be reduced. Effectively improve.

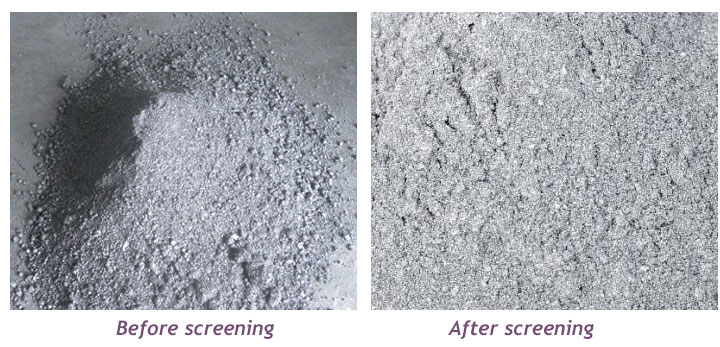

1. The screening material is more refined

For some fine powder and micropowder materials, it is difficult to perform accurate screening with other vibrating screen equipment, especially for materials above 100 mesh, vibro sifter can easily complete fine screening and leakage. Whether the material is dry or wet, fine or coarse, specific gravity or light, it can be screened from 0 to 400 mesh, and whether it is liquid or slurry, 0-600 mesh can be filtered.

2. Higher screening output

The vibro sifter has 1~5 layers of screens, which can be used in single or multiple layers. A vibro sifter equipment can be equipped with 5 layers of screens at the same time and divided into 6 grades. In order to meet the needs of various industries for fine screening as much as possible, vibro There are various types of sifter. Different types of vibro sifter correspond to different screening areas, and the corresponding screening efficiency and processing capacity are also very different, which can fully meet the fine powder screening needs of different industries.

3. With mesh cleaning device,not clogged

The net cleaning device of vibro sifter is a bouncing ball (rubber and silica gel). The bouncing ball of vibro sifter will bounce up and down to hit the screen during work, thereby avoiding the blockage of the mesh.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.