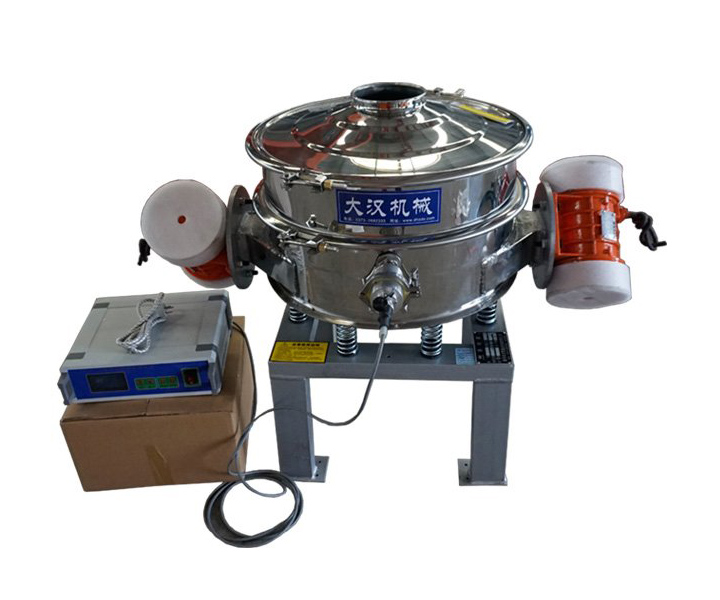

Suitable for rough inspection screening and impurity removal of powders and granules, ideal for screening incoming ingredients and final production inspection of finished products

![]()

![]()

Price:$760.00-$3,090.00/Set

Consult now and enjoy a 10% discount

Model: 600-1500 Screening accuracy: 140 mesh

Capacity: 3-30 tons/hour Power: 2×(0.18-0.75)kW

Motor speed:1460r/min

Customizable: Single motor/Double motor/Explosion-proof type/Ultrasonic type (As you need)

Application: Suitable for safety screening of raw materials, process screening, inspection screening, dust removal and mainly for pre-package screening, such as flour, washing powder, metal powder, chemical powder, fertilizer and other industries

Commitment:

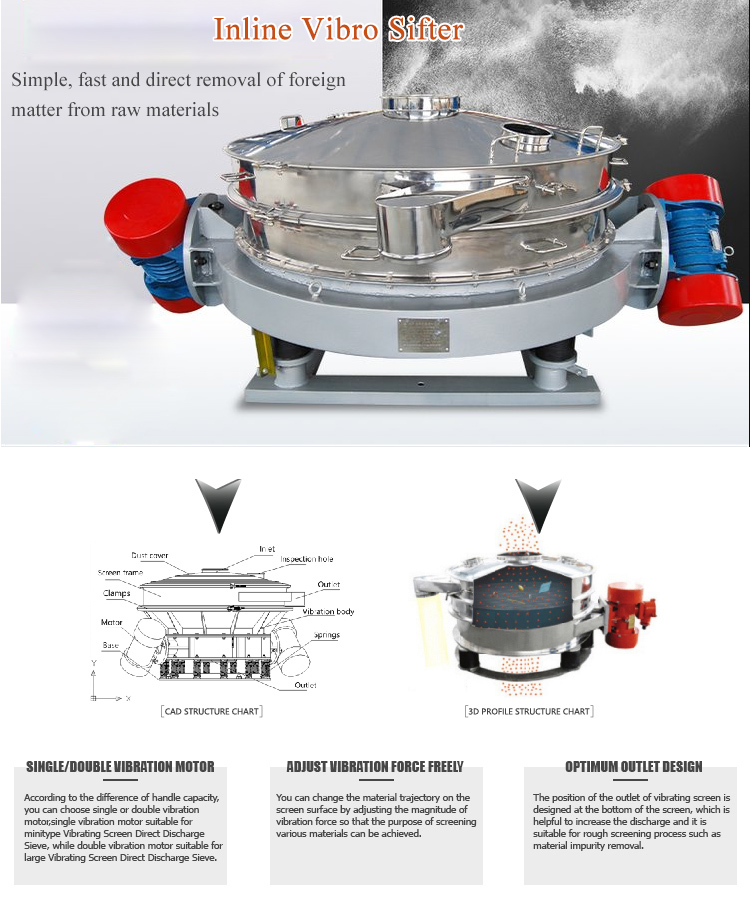

Inline vibro sifter, also called inline central discharge vibro sifter, can quickly remove foreign matter in raw materials, suitable for raw material safety screening, process screening, inspection screening, dust removal and mainly used for pre-packaging screening.

The main advantage of Inline vibro sifter is that the inlet and outlet are on the same center line, which helps to reduce the movement of materials in the screening machine, thereby shortening the screening time, and the output is 2-5 times that of the ordinary round vibro sifter.

Double motor inline vibro sifter: There are two vertically mounted motors on each side, the material vibrates horizontally and circularly on the screen surface, it helps to improve the vibration and passing capacity, and has the function of automatic discharge.

Single motor inline vibro sifter: only one vibration motor is installed on one side, the material mainly vibrates up and down on the screen surface, and there is no automatic discharge function.

Inline vibro sifter is mainly for the screening of flour powder materials, and the maximum mesh size of flour powder materials is 140 mesh, so the maximum screen mesh number of the inline sifter is 140 mesh, which can be installed under the bulk silo. The powder is safely screened and can also be installed in bakeries and food processing plants of all sizes. In addition, the in-line screen can be used with the feeding station (dust-free feeding station) to unload and inspect small or large bags of flour to avoid dust problems during screening.

The sieved material or under sieve is discharged at the bottom outlet of the inline vibro sifter, and the bottom outlet is located just below the top inlet, allowing the material to fall vertically through the screen, and the material larger than the screen aperture stays on the screen surface and is discharged from the upper discharge port , the material smaller than the screen aperture will quickly pass through the screen and be discharged from the bottom discharge port.

Rough sieving and impurity removal

It mainly removes agglomeration, foreign matter and contaminants in the product, usually the impurity content is around 5%, which is very suitable for screening powder or granules in large quantities.

Large output

The inlet and outlet are in the same vertical direction, and the finished product under the screen quickly passes through the screen, reducing the residence time of the material on the screen surface, and the output is 3-5 times that of the ordinary vibro sifter.

Use in tandem systems

The single vibration source is used directly in series in the pipeline to remove foreign matter and impurities in the pipeline without manual operation and avoid secondary pollution.

No dust pollution

The sealing is strict, the liquid does not leak, and the dust does not fly. It can be used with a dust-free feeding station to achieve dust-free powder screening.

Small footprint

The motor is designed on the outside of the equipment, reducing the height of the equipment and making effective use of space.

Very flexible

The compact body, with casters, is highly mobile and easy to operate.

Coal particles inline vibro sifter

Milk powder inline vibro sifter

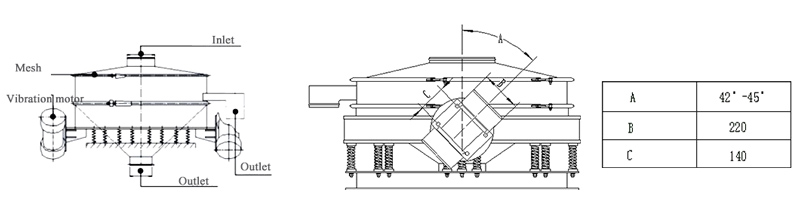

| Model | Power(kw) | RMP(r/min) | Sieve diameter(mm) | A | B | C |

| ZPS-600 | 0.18 | 1460(960) | 520 | 1070 | 600 | 502 |

| ZPS-800 | 0.25 | 720 | 1390 | 800 | 525 | |

| ZPS-1000 | 0.37 | 890 | 1566 | 970 | 543 | |

| ZPS-1200 | 0.55 | 1090 | 1875 | 1170 | 814 | |

| ZPS-1500 | 0.75 | 1390 | 2226 | 1470 | 875 |

In addition to the conventional models, the inline vibro sifter produced by Xinxiang Dahan can also be designed according to the needs of different industries or users, such as ultrasonic type, edge type, gate type, baffle type, etc. You can provide the following data: material name, mesh number , output, specific gravity, installation location. So that the technology can provide you with the corresponding equipment production plan according to your requirements.

1. The application standard of inline vibro sifter in the production process of the food and pharmaceutical industries is mainly hygienic. The equipment used in the production of the food industry cannot pollute the product, so the material needs to use 304 stainless steel.

2. In the production process of the chemical industry, since many materials are corrosive or liquid, the material of the machine needs to be made of 304 stainless steel or higher 316L stainless steel, and a closed design is required to prevent liquid leakage.

3. The main problem to be solved in the production process of the powder industry is powder escape, so when the sieve machine is used in this industry, it is necessary to adopt a closed design and a leak-proof material design.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.