Fill the silo with the material at one time, and then adjust the butterfly valve on the silo to control the flow of the flow into the vibrating screen of the silo for screening.

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Screening mesh: within 500 mesh (25 microns)

Output: 1-5 tons/hour

Screening materials: starch, soybean milk, soy sauce, monosodium glutamate, resin powder, paint, traditional Chinese medicine powder, electromagnetic materials, plastic particles, washing powder, etc.

Can be rotated and moved 360 degrees

Commitment:

Silo Vibro Sifter has a feeding bin above the feeding end, which can fill the bin with materials at one time, and then control the material entering the rotary vibrating screen by adjusting the butterfly valve on the bin. The feature of Silo Vibro Sifter is that it can realize intermittent feeding and It has a certain storage function, which saves the time cost and labor cost of manual feeding. The existence of the silo can also play a certain buffering role and protect the screen. The function of Silo Vibro Sifter butterfly valve is not only to control the size of feed flow, but also to improve the screening accuracy of materials.

The Silo Vibro Sifter made of all-carbon steel is painted with carbon steel as a whole, and its wear resistance and corrosion resistance are average. Painting can delay rust, improve wear resistance to a certain extent, and also play an aesthetic role to a certain extent. It is mainly used to process abrasives, plastics, sand and other materials that have no special properties and do not require high screening hygiene.

The Silo Vibro Sifter made of all stainless steel is 304 or 316L stainless steel as a whole, which is resistant to acid and alkali corrosion, rust and wear resistance, and can withstand high-temperature material screening up to 300 ℃. It is also used in the production of appliances for the food and pharmaceutical industry The material is safe and hygienic, and it can handle food and medical materials such as sugar, flour, nuts, tablets, and raw materials. It can also be used in the chemical industry.

The plastic Silo Vibro Sifter is made of PVC as a whole, which has strong corrosion resistance, is metal-free and non-magnetic, and is suitable for screening some special materials that will react with metals, such as zirconia, fluorescent agents and others. chemical additives.

1. Self-contained silo, butterfly valve to adjust uniform feeding, saving manual screening and high efficiency, with a certain storage function

2. The silo is set above the feed inlet to play a certain buffering role, avoiding the excessive drop and causing the material to directly hit the screen, resulting in damage to the screen

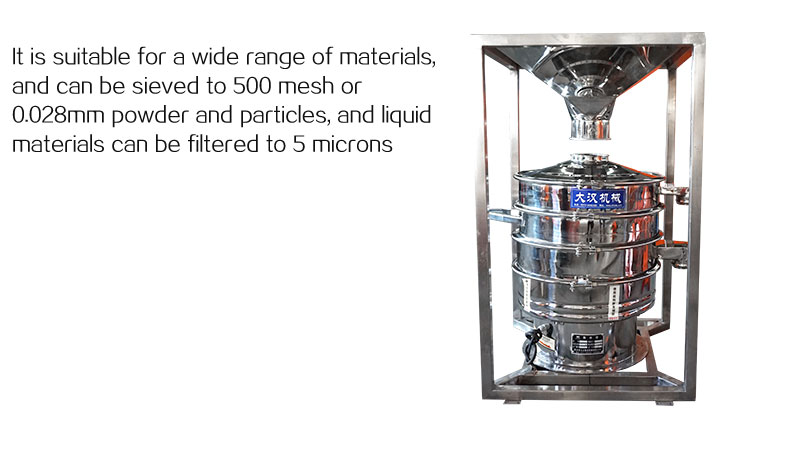

3 It is suitable for a wide range of materials, and can be sieved to 500 mesh or 0.028mm powder and particles, and liquid materials can be filtered to 5 microns

4. The flange design of the silo can be connected to the upper feeding device to realize the automatic production of the assembly line. The fully enclosed structure prevents dust spillage and improves the working environment.

5. Set up a net cleaning device to automatically clean the net. For viscous and static materials, an ultrasonic deblinding system can be installed

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 0.55 | 500 | ||||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Silo:Reduce the impact of materials on the screen, and the screen has a long life

Universal wheels: It is convenient for the machine to be transferred according to the change of the screening location

The material is stored in the silo, and the feeding flow of the silo is controlled by adjusting the butterfly valve of the silo, so that the material automatically and evenly enters the vibrating screen for screening. During the screening process, the bouncing ball of the net cleaning device under the screen continuously hits The sieve mesh enables the upper layer of the sieve to screen through the mesh smoothly, and effectively solves the problem of material blocking. The oversieve and undersieve are discharged from different outlets to achieve screening, impurity removal or filtration classification. Purpose. Adjusting the phase angle of the upper and lower ends can change the movement track of the material on the screen surface

The biggest feature of Silo Vibro Sifter is the increased silo design, which can better match the feeding of feeding equipment (storage barrel, screw feeder, vibrating feeder, mixer, etc.). Feed material capacity of vibrating screen.

At the same time, a butterfly valve is designed at the discharge end of the silo, which can be opened or closed according to the actual screening process.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.